Zipper installation edge curler for sewing machine

A technology of a crimper and a sewing machine, which is applied to sewing equipment, sewing machine components, cloth feeding mechanisms, etc., can solve the problems of asymmetric sewing of zippers, easy deviation in processing, and troublesome processing methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with drawings and embodiments.

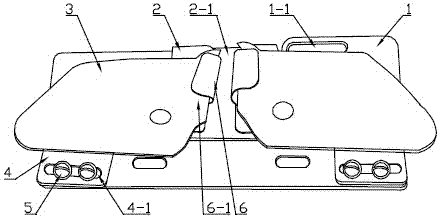

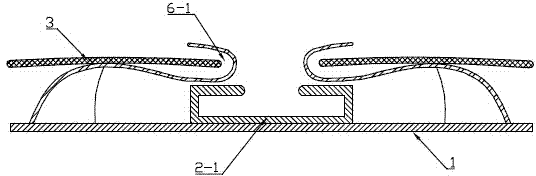

[0010] Such as figure 1 and figure 2 As shown, the present invention includes a bottom plate 1 and a curling plate. A zipper roll 2 is welded in the middle of the bottom plate 1, and the zipper roll 2 is bent to form a zipper placement groove 2-1. The zippers to be processed are placed in this groove.

[0011] There are two curling plates, which are distributed on both sides of the zipper rolling plate 2 . The curling plate includes a curved plate 6 and a horizontal plate 3, the horizontal plate 3 is welded on the curved plate 6, the curved plate 6 is bent to form a curling groove 6-1, the side of the curved plate 6 is horizontally bent to a fixed plate 4, and fixed The plate 4 is provided with a chute 4-1. The curved plate 6 and the fixed plate 4 are integrally formed.

[0012] The two curling plates are distributed symmetrically with the zipper rolling plate 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com