Flow channel mechanism

A technology of flow channel and flow channel body, which is applied in the field of food automatic production tools, can solve the problems of fixed flow channel size, inability to adjust products, and inability to adapt to batch biscuit or senbei-like materials, so as to ensure smoothness and avoid mutual interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

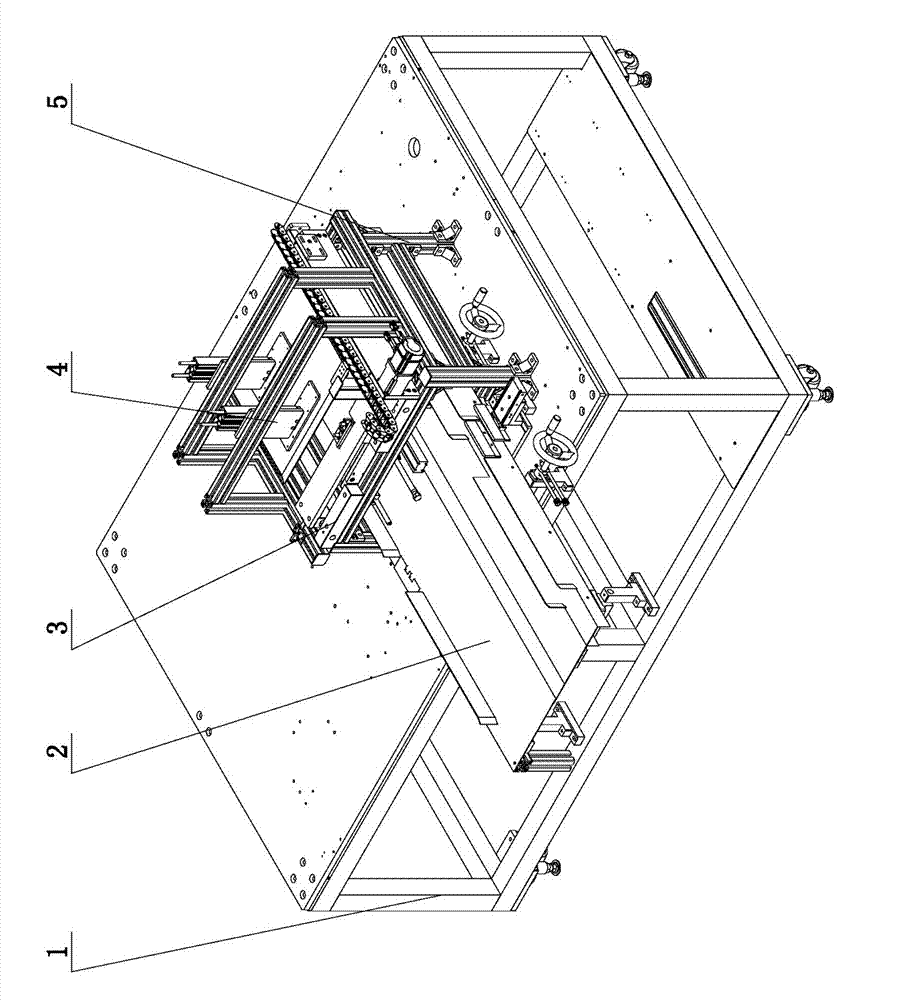

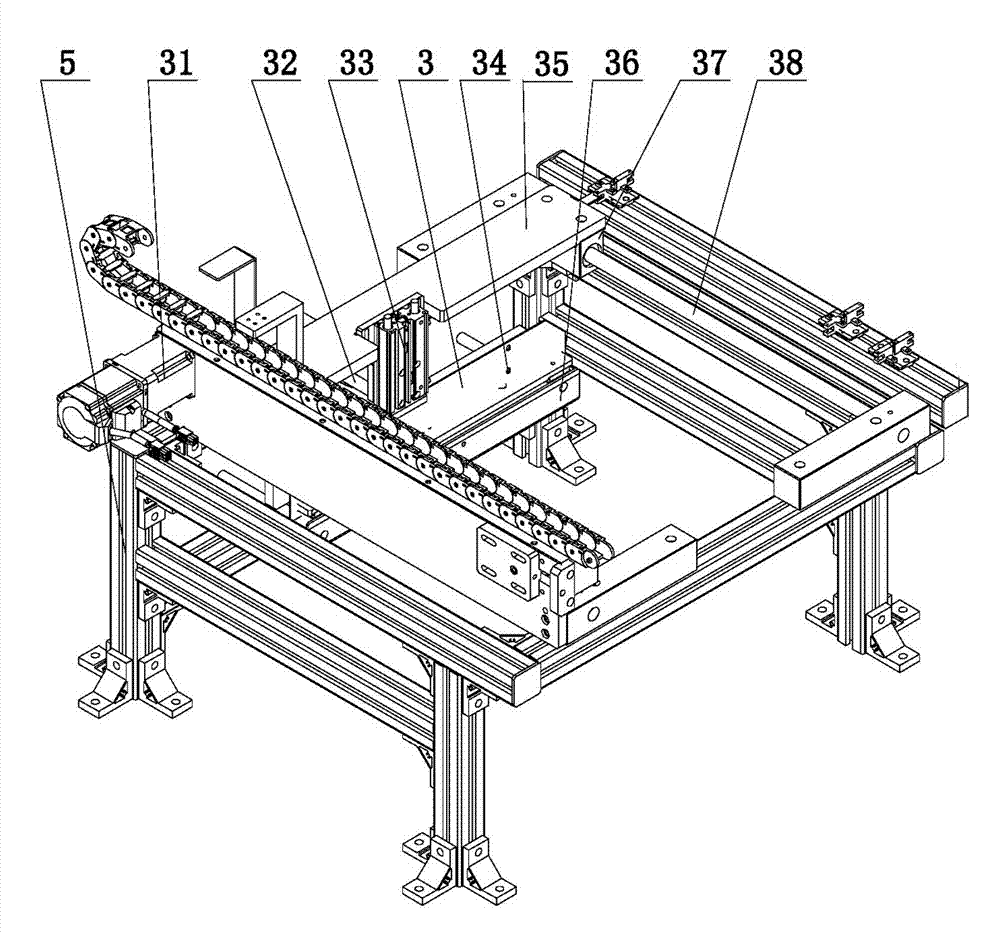

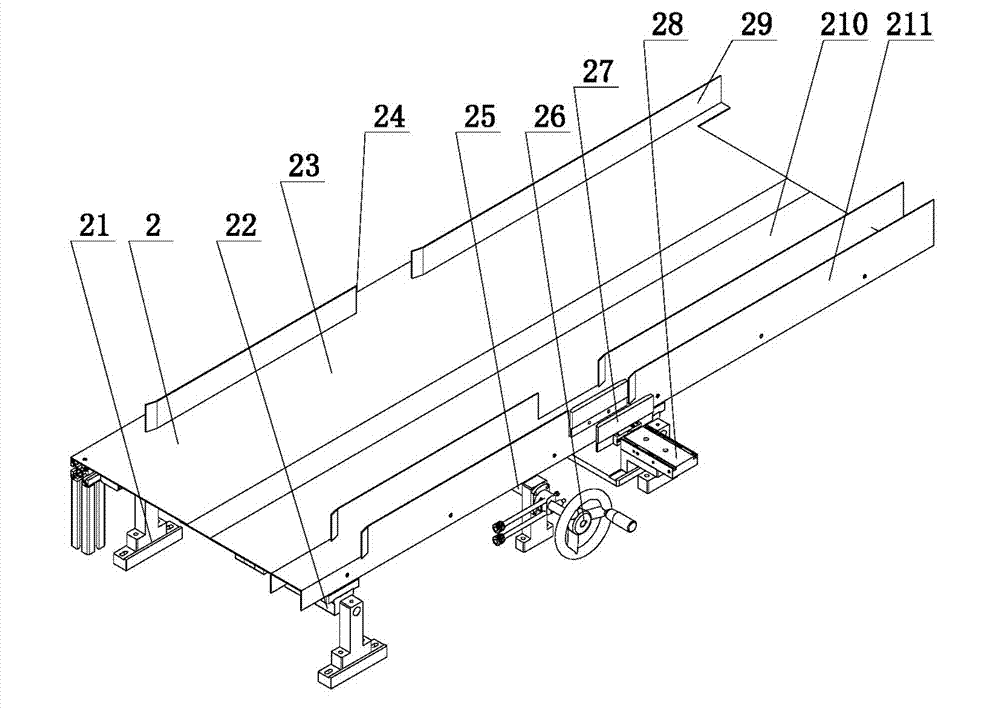

[0027] The present invention comprises frame 1, and it is characterized in that: frame 1 is provided with the runner body 2 that is made of reference channel 23 and moving channel 210, and one end of reference channel 23 and one end of moving channel 210 are alternately arranged; The other end is provided with a reference rib 29, and the other end of the moving path 210 is provided with a moving rib 211; the frame 1 is provided with a ball screw 25 perpendicular to the runner body 2, and the moving path 210 is the same as the ball screw. The silk nut on the 25 is fixedly connected.

[0028] One end of the flow channel body 2 is arranged on the frame 1, and the bottom of the other end of the flow channel body 2 is provided with a mounting base, the mounting base is provided with a first linear bearing 22, and the bottom of the moving channel 210 is provided with a first linear bearing 22. The line bearing 22 fits the first guide shaft. The first guide shaft plays a guiding rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com