A new multi-variable predictive control method for thermal power unit load

A technology of thermal power unit and predictive control, applied in adaptive control, general control system, control/regulation system, etc., can solve the problem that the dynamic coordination between the boiler side and the steam turbine side cannot be realized, the project cannot realize online real-time control, and the calculation amount is large. To achieve stable economic operation, speed up load response speed, and achieve the effect of dynamic coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

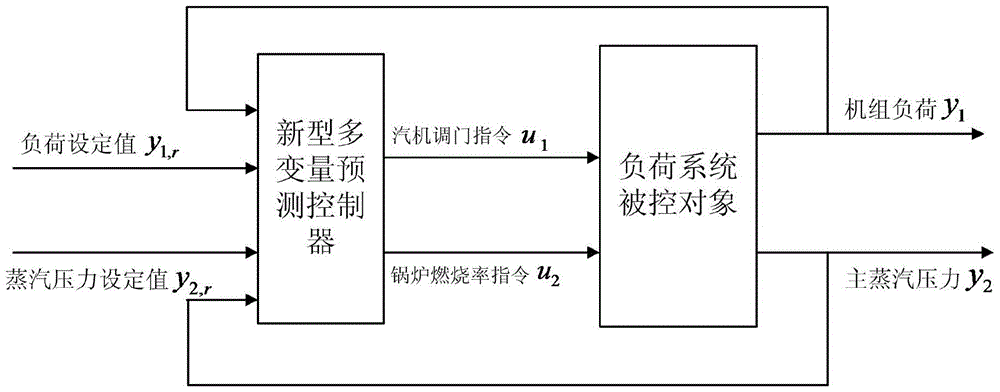

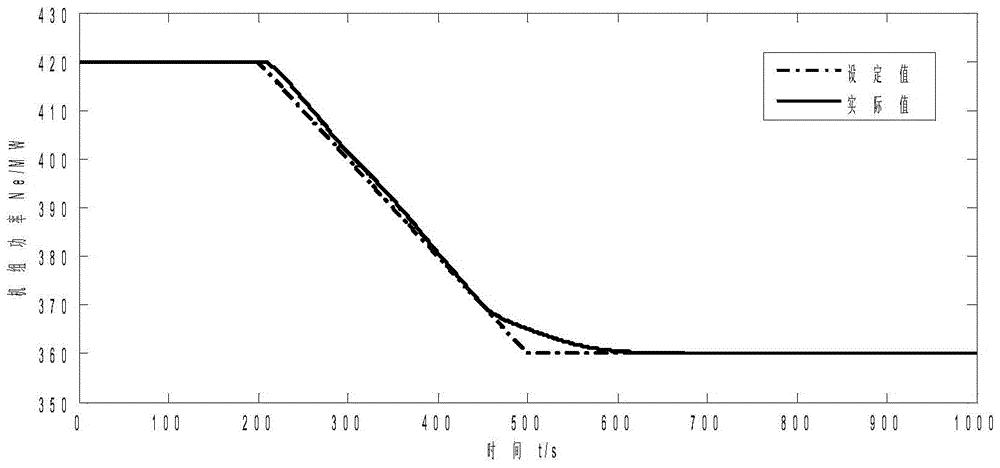

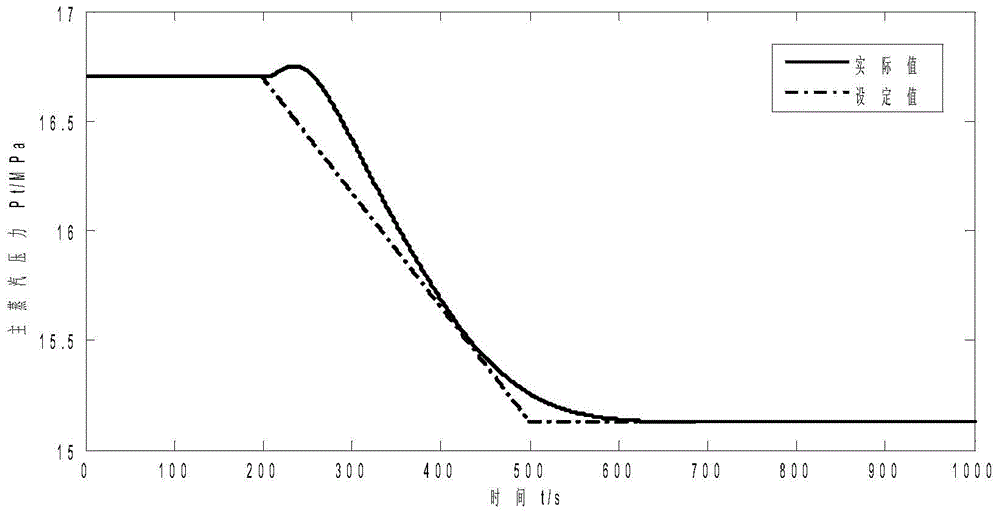

[0041] Step 1: Adjust the door opening u according to the steam turbine respectively 1 , boiler firing rate u 2 is the step quantity, get the unit load y 1 and the main steam pressure y 2 The step response value of the step response value; the above response data is fitted by the least squares system identification method, and the following transfer function is obtained: 1 is the input, load y 1 is the output steam turbine valve-load transfer function G 11 ; Take boiler combustion rate u 2 is the input, load y 1 is the output firing rate-load transfer function G 12 ;Use the steam turbine to adjust the door opening u 1 is the input, the main steam pressure y 2 is the output steam turbine valve-main steam pressure transfer function G 21 ; Take boiler combustion rate u 2 is the input, the main steam pressure y 2 is the output firing ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com