Bunched cable connecting socket, bunched cable connecting plug and bunched cable testing fixture

A technology for bundling cables and connecting sockets, which is applied in the direction of two-part connection device, parts of the connection device, connection, etc., can solve the problems of easy twisting, low efficiency, high labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

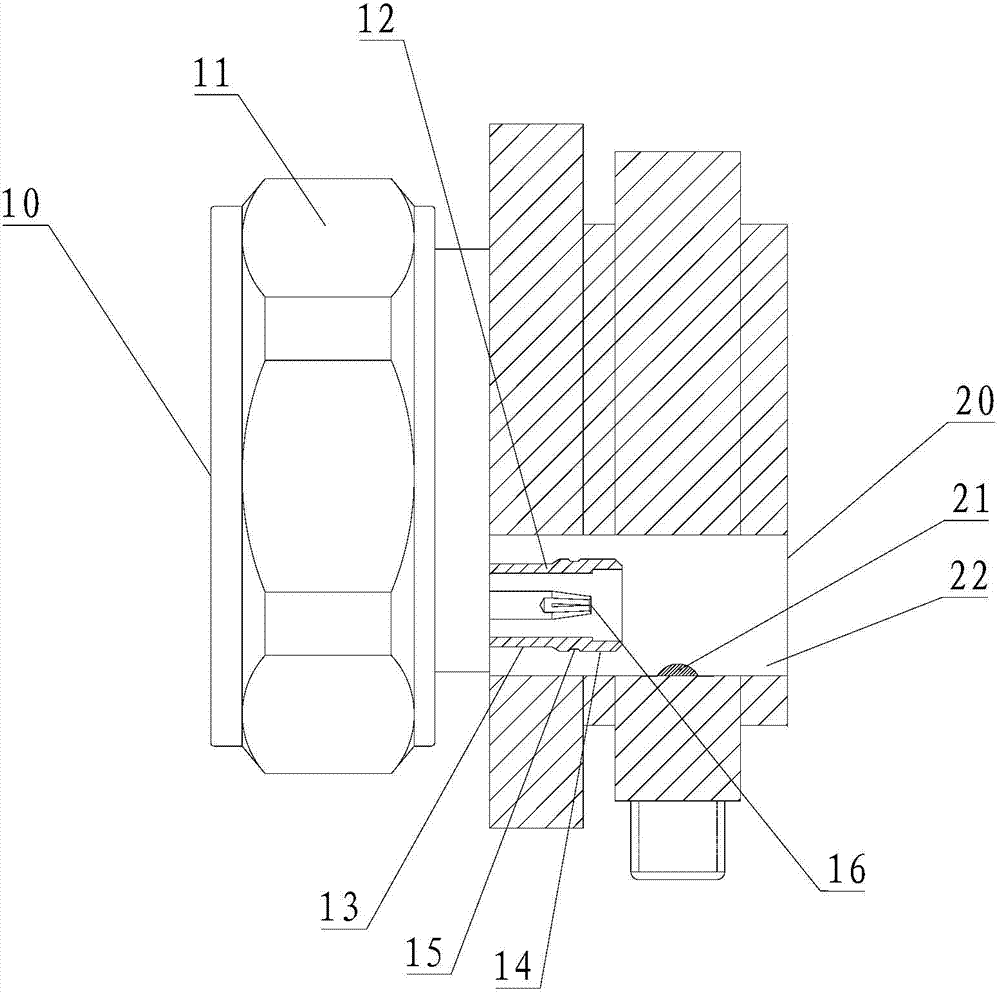

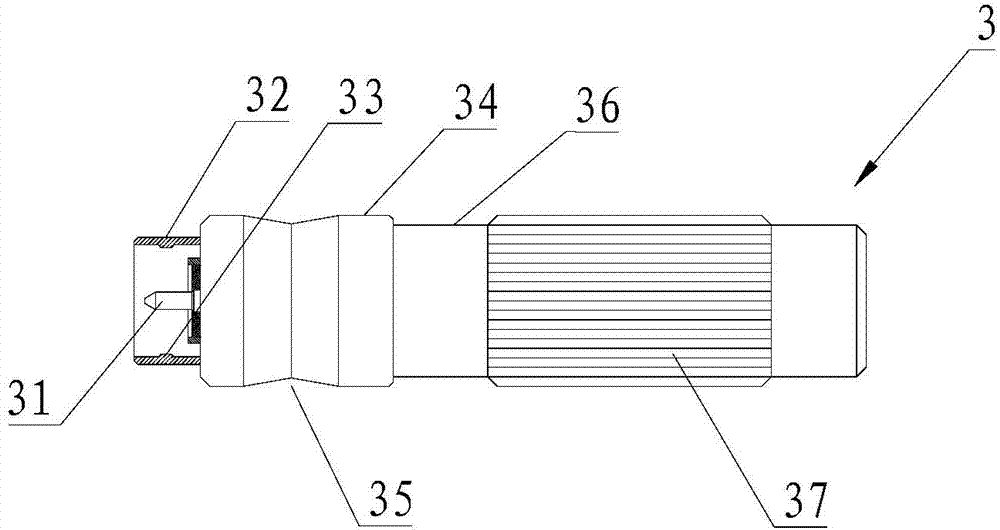

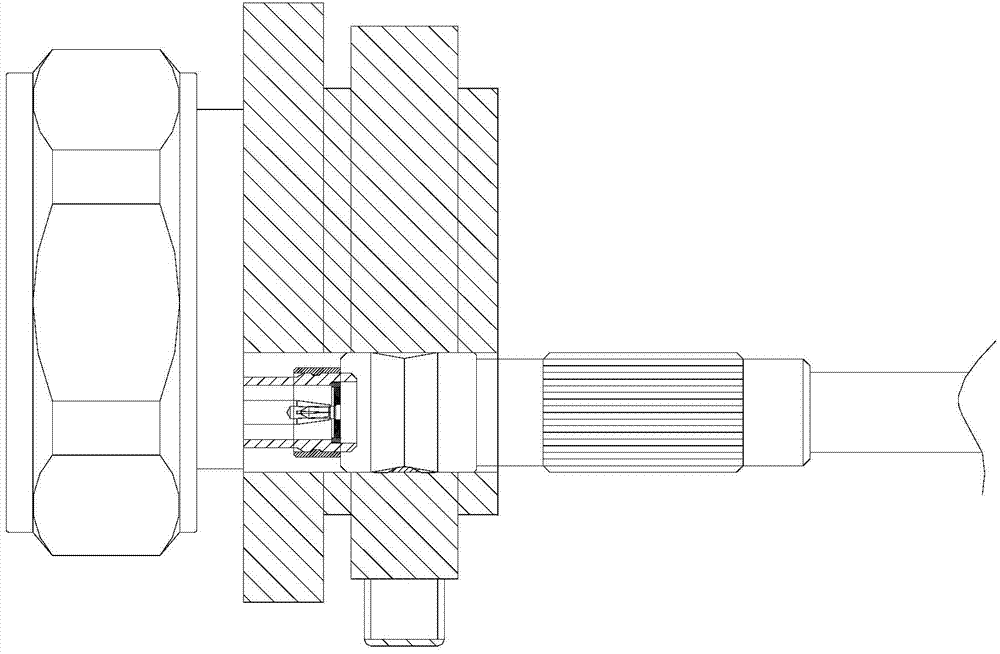

[0022] One end of the main body is provided with a first socket 10 , and a locking nut 11 is provided on the outside of the main body corresponding to the first socket 10 , so that the first socket 10 of the main body can be locked on the required equipment through the locking nut 11 . Correspondingly, the other end of the main body is provided with a plurality of second sockets 20 , and the main body is provided with a connecting structure corresponding to each second socket 20 . That is, the socket of the present invention can be designed as a one-to-many connection mode, that is, the first socket 10 is the main port, so it occupies a large area and is usually arranged in the middle of the main body, while the second socket 20 is each external detection port. Therefore, more are distributed on the other surface of the main body. In order to ensure convenient connection, each second socket 20 is provided with the above-mentioned connection structure, so that the multi-line acc...

Embodiment 2

[0024] Such as Figure 4 , 5 As shown, in this embodiment, the main body is mainly composed of two parts, the main seat 1 and the auxiliary seat 2 . Wherein, one end of the main seat 1 is provided with a first socket 10, and the other end is provided with a flange 17, and the sub-seat 12 in the connection structure (the structure with multiple sub-seats 12 as shown in the figure) is arranged at the other end of the main seat. Lan 17 on. Corresponding to the main seat, a flange 23 is provided at one end of the auxiliary seat 2, and a second socket 20 and a guide hole 22 for the connection structure are provided at the other end. Further, the main seat 1 and the auxiliary seat 2 are attached to each other through respective flanges 17, 23 and connected by means such as bolts.

[0025] The biggest benefit of splitting the socket main body into two parts by adopting the scheme of this embodiment is to simplify the production process of the socket with complex structure. The gu...

Embodiment 3

[0027] The outer surface of the connecting section of the sub-seat 12 is plane.

[0028] In this embodiment, the outer surface of the sub-seat 12 is a plane, which means that it is not a threaded surface of a conventional common connector, so that it can support the axial entry and exit of the plug, and facilitate the realization of the quick plug-in and pull-out function.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap