Thresher based on differential inversion principle of corn ear grains

A technology of corn ears and threshers, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve problems such as grain damage, and achieve the effect of ensuring detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The core of the present invention is that, according to the grain growth law of corn ears, that is, corn grains are arranged in rows and rows on similar cone-shaped corn ears, and based on this, a corn ear threshing device is provided, which can remove the kernels along the rows of ears. drop without causing damage to the corn kernels.

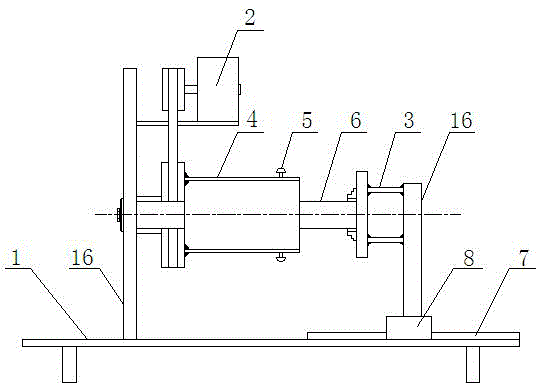

[0018] Such as figure 1 As shown, a thresher based on the principle of differential inversion of corn ear grains includes a frame 1, a motor 2, a threshing device 3 for corn ears 6, a clamping device 4, and a detachable central shaft 42, wherein the motor 2 It is fixed on the frame 1, and the upper end surface of the frame 1 is oppositely provided with two vertically arranged risers 16, and the ends of the clamping device 3 and the threshing device 4 are respectively fixed on the two risers.

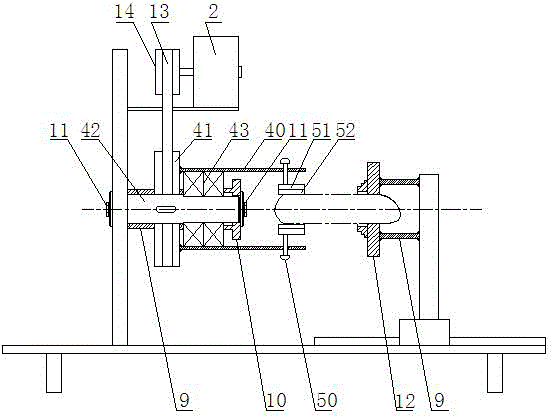

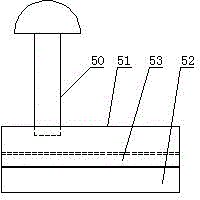

[0019] Such as figure 2 As shown, the threshing device 4 includes a drum 40 that can be sleeved on the outside of the corn ear 6 clamped by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com