Double fish-shaped reactor

A reactor and reaction technology, applied in the direction of microcapsule preparation, microsphere preparation, etc., can solve the problems of poor operability and practicability, and achieve the effects of easy adjustment, rapid mixing, and stable branch flow distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0028] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

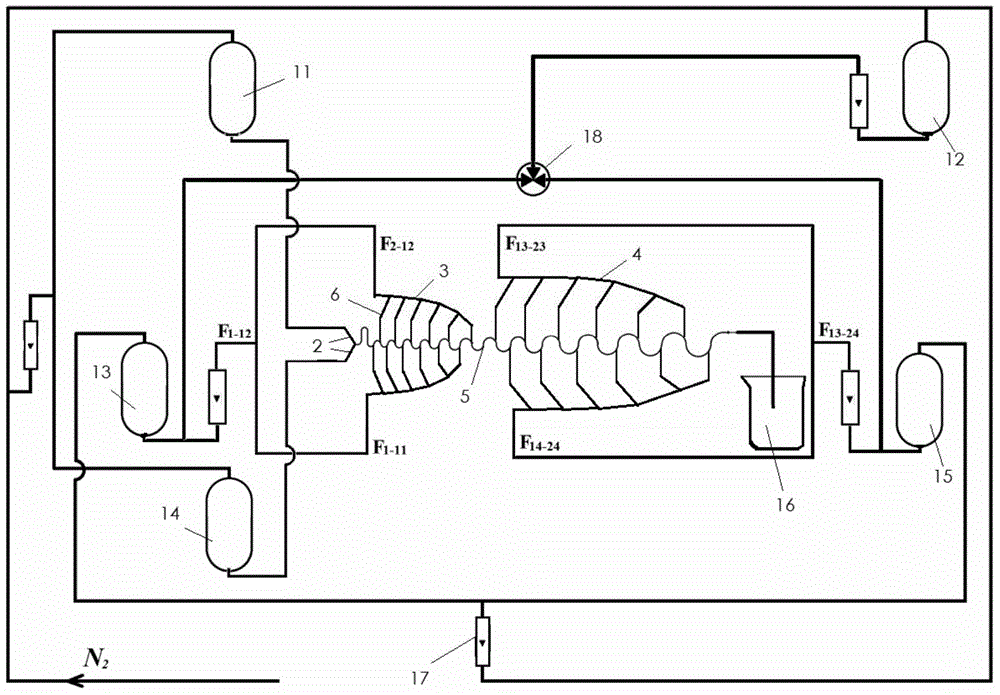

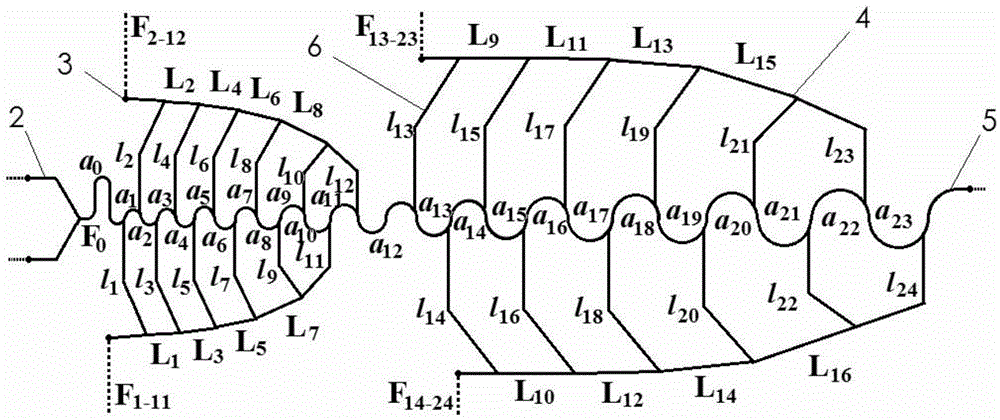

[0029] figure 1 Shows the structure of an embodiment of the present invention when it is applied. The double fish-shaped reactor provided by the embodiment of the present invention is connected to a material liquid supply and storage system. The material liquid supply and storage system includes six storage tanks, which can produce stable and continuous The high-pressure gas source of pressure nitrogen N2 (such as: air compressor or cylinder gas) and multiple connecting pipes, pipe fittings, multiple flow meters 17 (including liquid flow meters and gas flow meters), pressure gauges (not shown), Three-way valve 18 and so on. The six storage tanks are storage tank 11, storage tank 12, storage tank 13, storage tank 14, storage tank 15, and storage tank 16. Due to the difference in the quantity and nature of the stored liquid, the size and material of each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com