Bamboo and wood equilateral polygon milling machine

A multi-faceted, milling machine technology, applied to wood processing appliances, processing machines for manufacturing flat surfaces, manufacturing tools, etc., can solve problems such as uneven processing and inconsistent thickness of original bamboo side walls, and achieve simple structure and low installation accuracy requirements , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

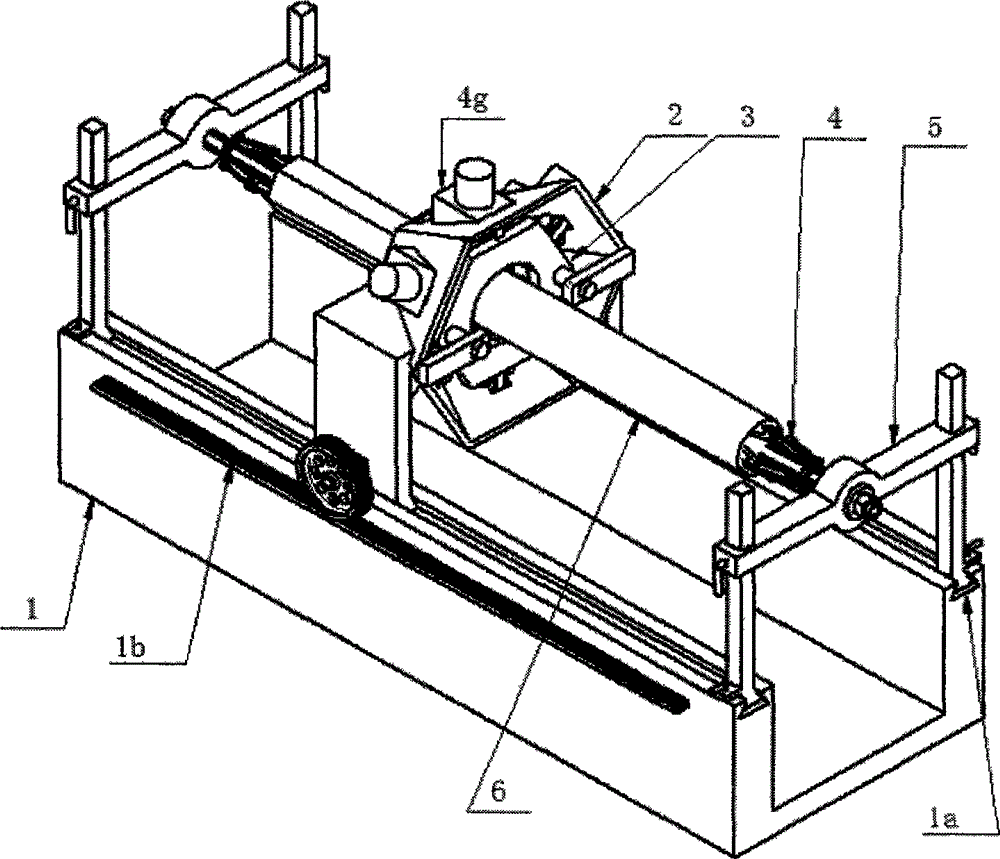

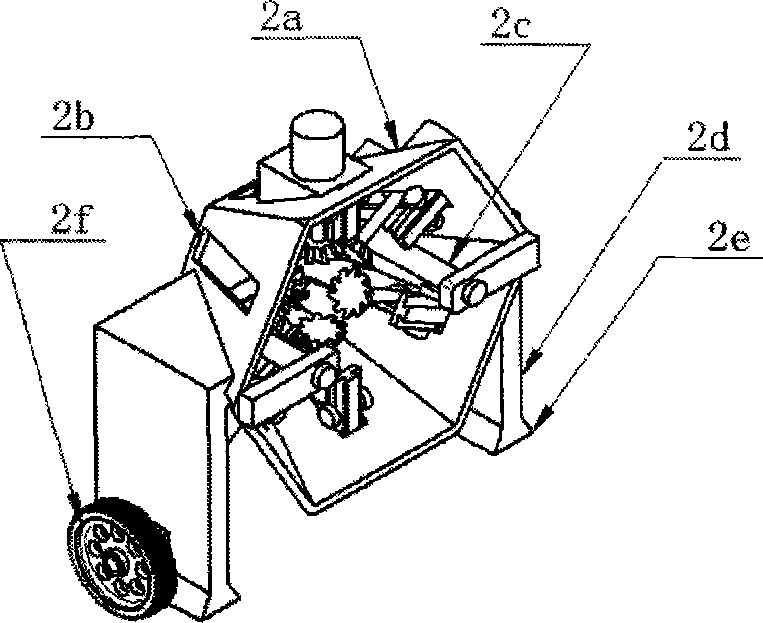

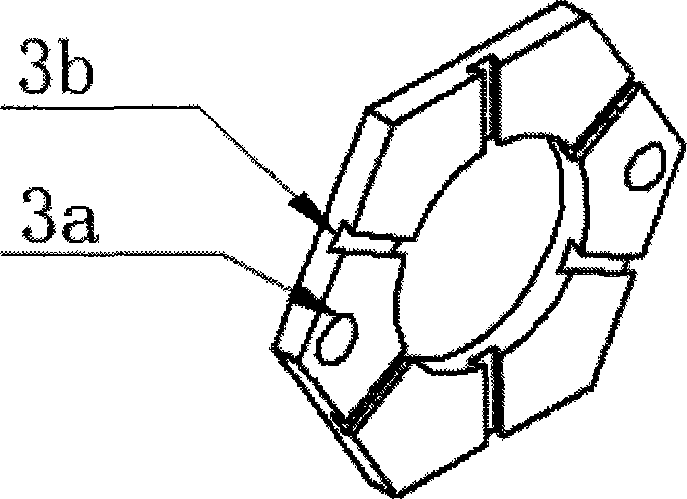

[0021] 1-base, 1a-base dovetail groove, 2-tool mounting platform, 2a-hollow positive edge platform, 2b-tool base mounting groove, 2c-guide rail, 2d-support leg, 2e-support leg dovetail tenon, 2f-drive gear , 3-tool adjustment plate, 3a-guide rail hole, 3b-tool adjustment plate dovetail groove, 4-fixed top claw, 4a-tool base slope, 4b-limit block, 4c-tool base dovetail tenon, 4d-limit rolling Body, 4e-vertical through hole, 4f-tool upper plane, 4g-tool base, 5-top claw bracket, 5a-top claw shaft, 5b-ejector rod, 5c-connecting rod, 5d-slider, 5e-adjusting nut , 6-original bamboo, 6a-longitudinal strut, 6b-horizontal strut, 6c-axial adjustment nut

[0022] attached Figure 1-6 A specific embodiment of the invention is given. Taking the processing of hexagonal bamboo as an example, it is described as follows in conjunction with the accompanying drawings.

[0023] Bamboo and wood hexagonal milling machine, including base (1), used for installing and connecting other parts, its c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com