AGV drive independent suspension vibration reduction mechanism

A vibration damping mechanism and independent suspension technology, applied in the direction of suspension, elastic suspension, control device, etc., can solve the problems of high installation difficulty, prone to rollover, etc., achieve good vibration damping effect, improve the maximum force capacity, Strong grip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

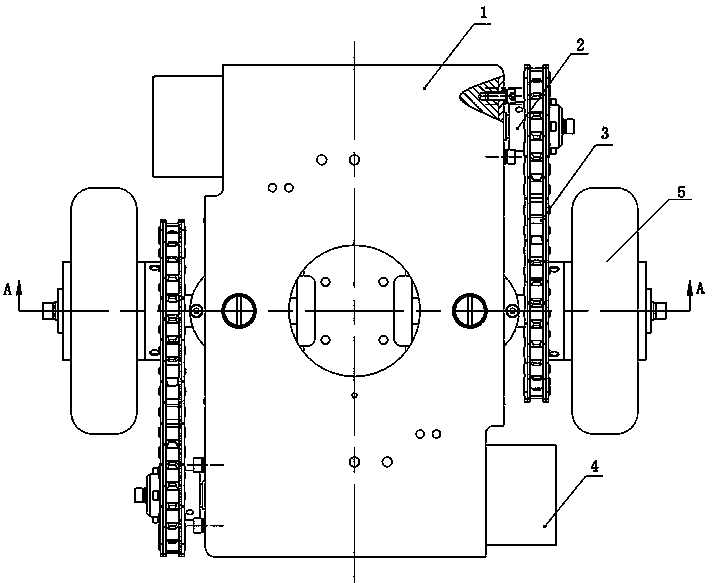

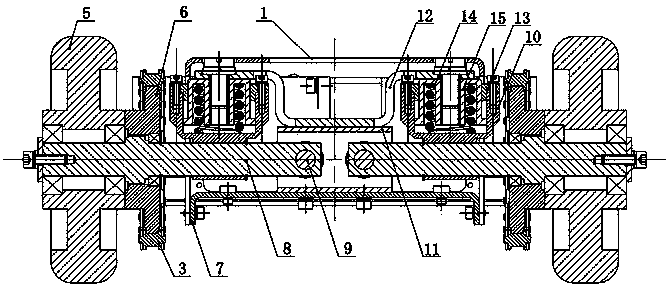

[0018] Such as figure 1 and figure 2 As shown, an AGV drives an independent suspension damping mechanism, which includes a drive mounting plate 1, a gear motor 4, a chain transmission, a vibration damping device, a drive shaft 8 and a drive wheel 5, and the gear motor 4 is installed on the drive mount plate 1 , there are two driving shafts 8, the driving shafts 8 are installed on the lower side of the driving mounting plate 1, the two driving wheels 5 are respectively installed on the outer ends of the two driving shafts 8, and the inner ends of the two driving shafts 8 are rotatably installed On the lower side of the drive mounting plate 1, damping devices are respectively arranged between the two drive shafts 8 and the drive mounting plate 1; The sprocket 2 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com