A gearbox transmission system for a 310g high-speed two-for-one twister

A transmission system and two-for-one twisting machine technology, which is applied to spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve the problems of insufficient lubrication, wear of various parts, low production efficiency, etc., and achieve convenient processing , Fewer components and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

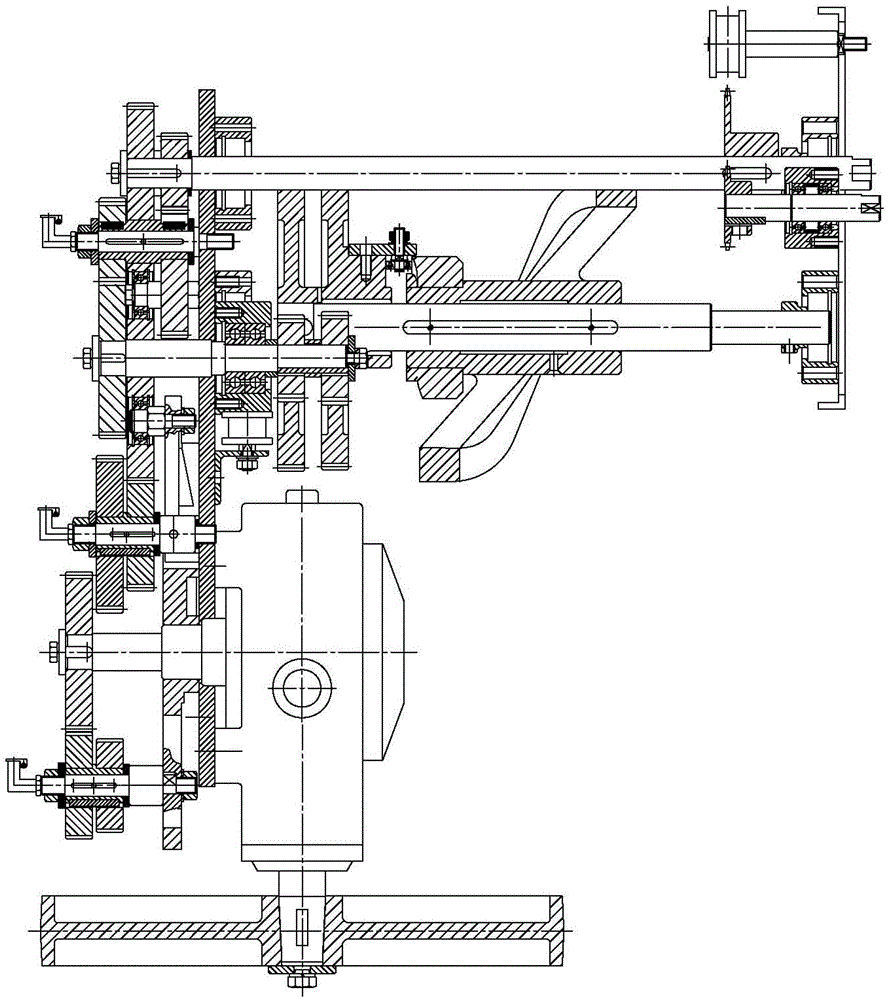

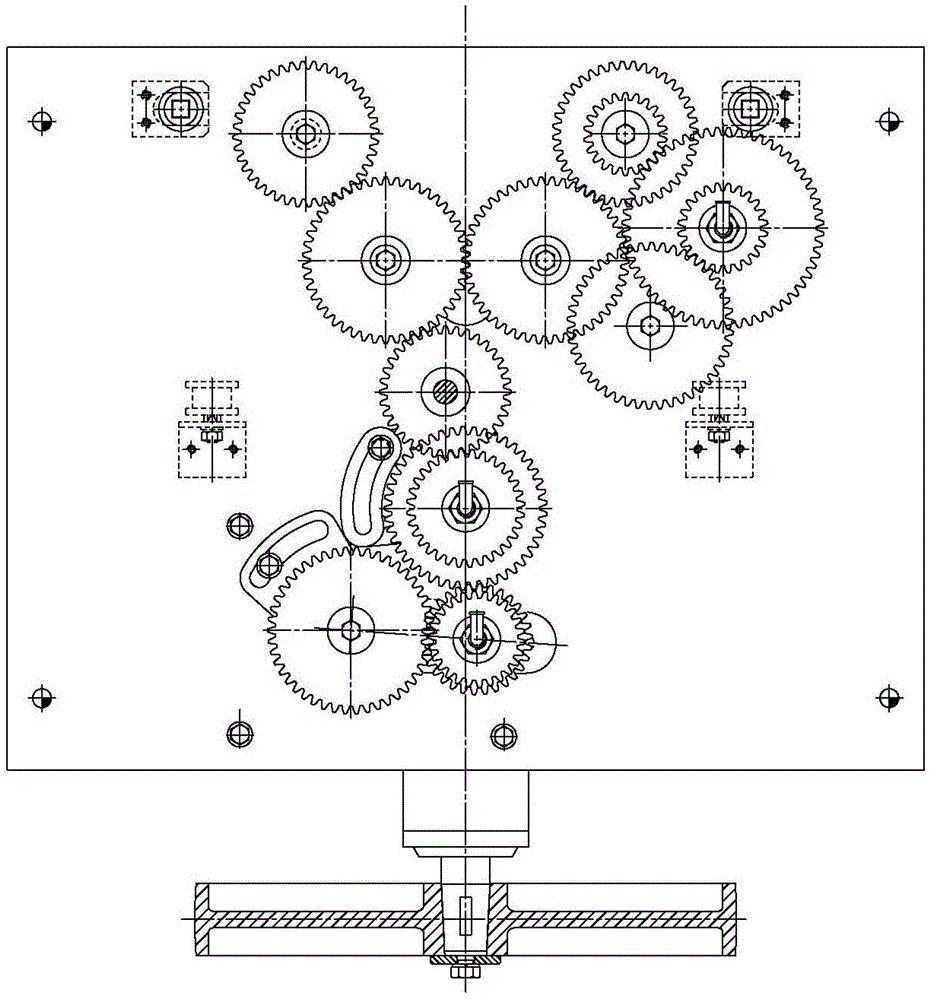

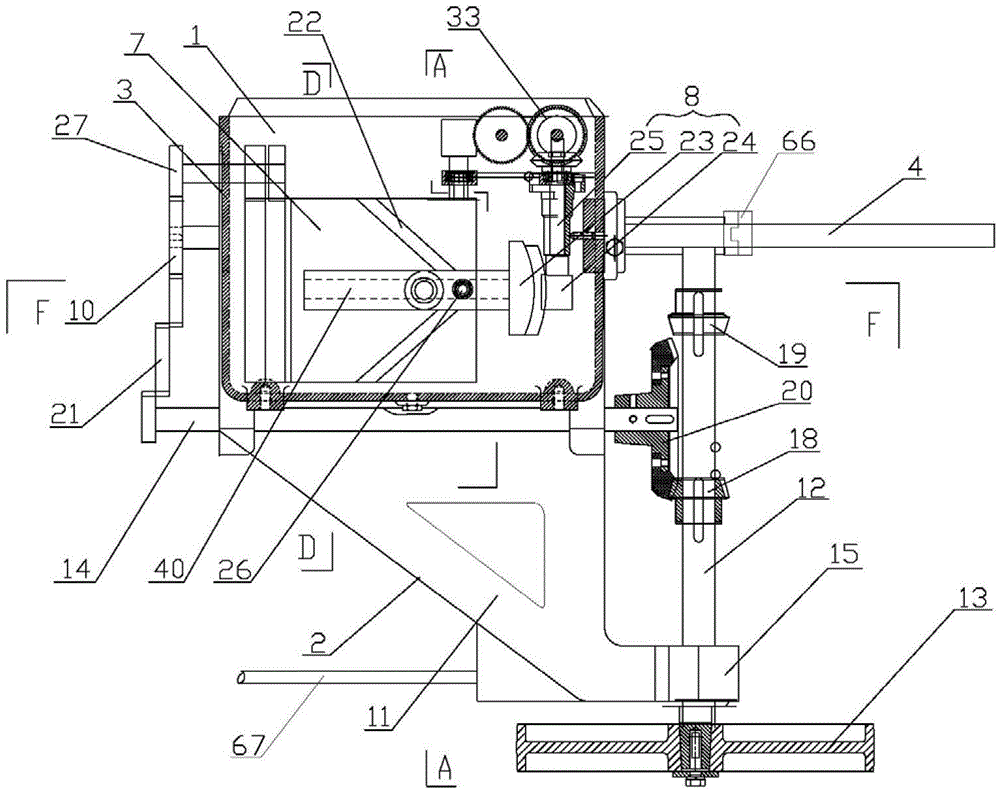

[0031] Please refer to the attached image 3 to attach Figure 8 As shown, the present invention is a gear box transmission system of a 310G high-speed two-for-one twister, which is assembled from several parts such as a fully enclosed transmission box 1 and a flywheel bracket 2 of the main transmission shaft.

[0032] Wherein, the fully enclosed transmission box 1 is supported on the flywheel bracket 2 of the main transmission shaft. The fully enclosed transmission box 1 is mainly composed of a box body 3, a first friction roller transmission shaft 4, a second friction roller transmission shaft 5, a transmission gear set 6, a grooved cam 7, an edge receiving mechanism 8, and an electronic pulse device 9. composition. Wherein, the distance between the first friction roller transmission shaft 4 and the second friction roller transmission shaft 5 is 230±2cm, so that the universality of the transmission system is good.

[0033] Further, the first friction roller transmission s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com