Rebar bending machine

A technology of hoop bending machine and steel bar, which is applied in the field of steel bar hoop bending machine, can solve the problems of high labor intensity, different shapes of steel hoops, and low efficiency, and achieve the effect of high hoop bending efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0038] refer to figure 1 -14:

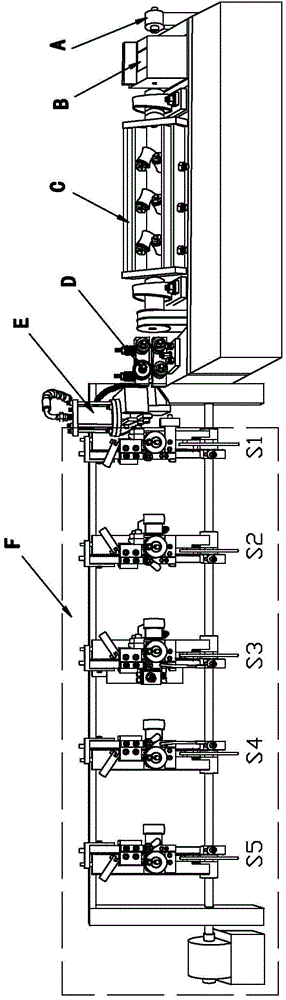

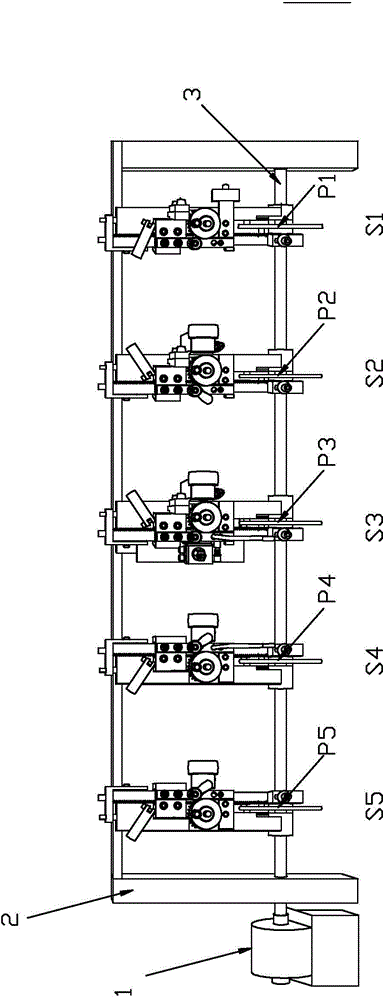

[0039] A steel bar hoop bending machine, including a positioning seat A, a cooling box B, a straightening frame C, a measuring instrument D, a cutting device E, and a hoop bending mechanism F; the feature is that the hoop bending mechanism F includes a main shaft 1 and a frame 2;

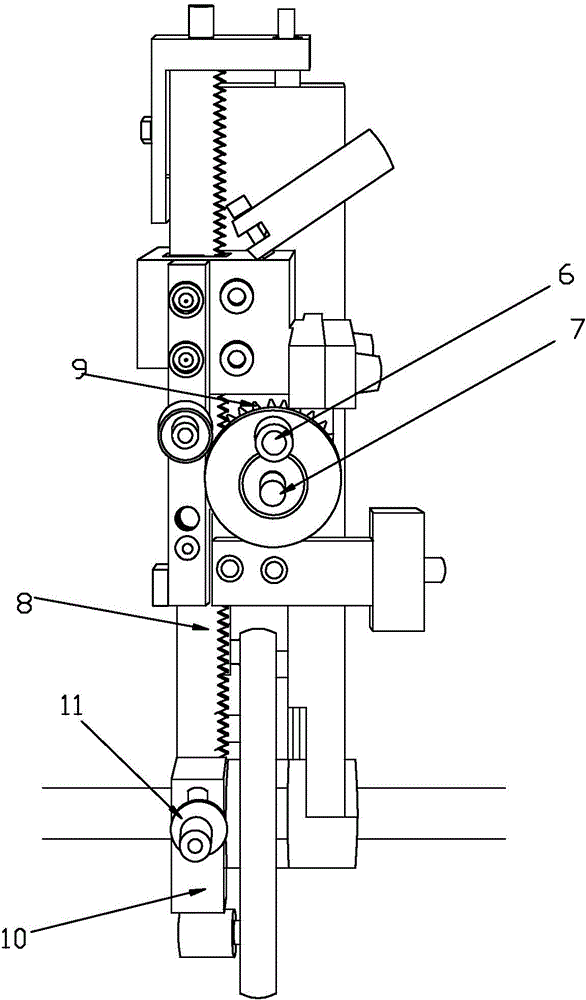

[0040] The main rotating shaft 1 is driven to rotate by a motor 3, and the first, second, third, fourth and fifth turntables P1, P2, P2, P3, P4, P5, wherein: the disk surfaces of the first, second, fourth and fifth turntables P1, P2, P3, P5 are all circular, and the disk surface of the third turntable P3 is oval; The third, fourth and fifth turntables P1, P2, P3, P4 and P5 are provided with first and second toggle wheels 4 and 5 on both sides of the turntables respectively;

[0041] The frame 2 is provided with first, second, thi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap