Automobile water cut bending equipment

A technology for automobiles and equipment, which is applied in the field of automobile water cutting and bending equipment, can solve the problems of increasing raw material costs, expensive stretch bending machines, and increasing procurement costs, and achieves the effects of simple structure, low manufacturing cost, and wide matching range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. In addition, it should be understood that after reading the teachings of the present invention, those skilled in the art may make various changes or modifications to the present invention, and these equivalent forms also fall within the scope defined by the appended claims of the present application.

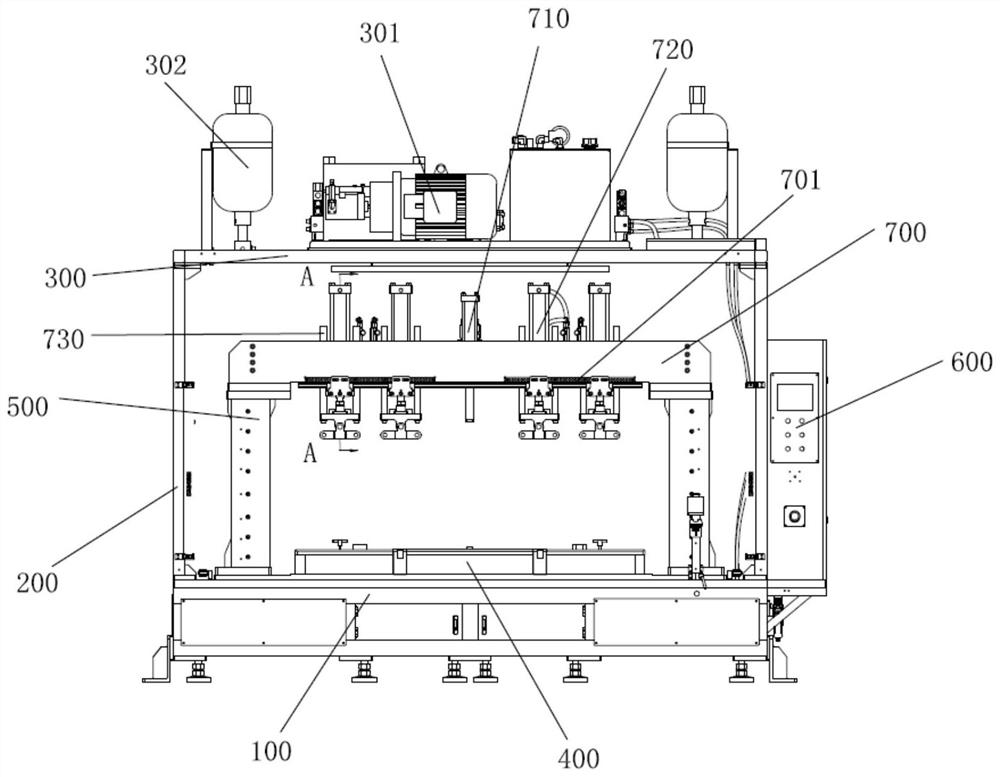

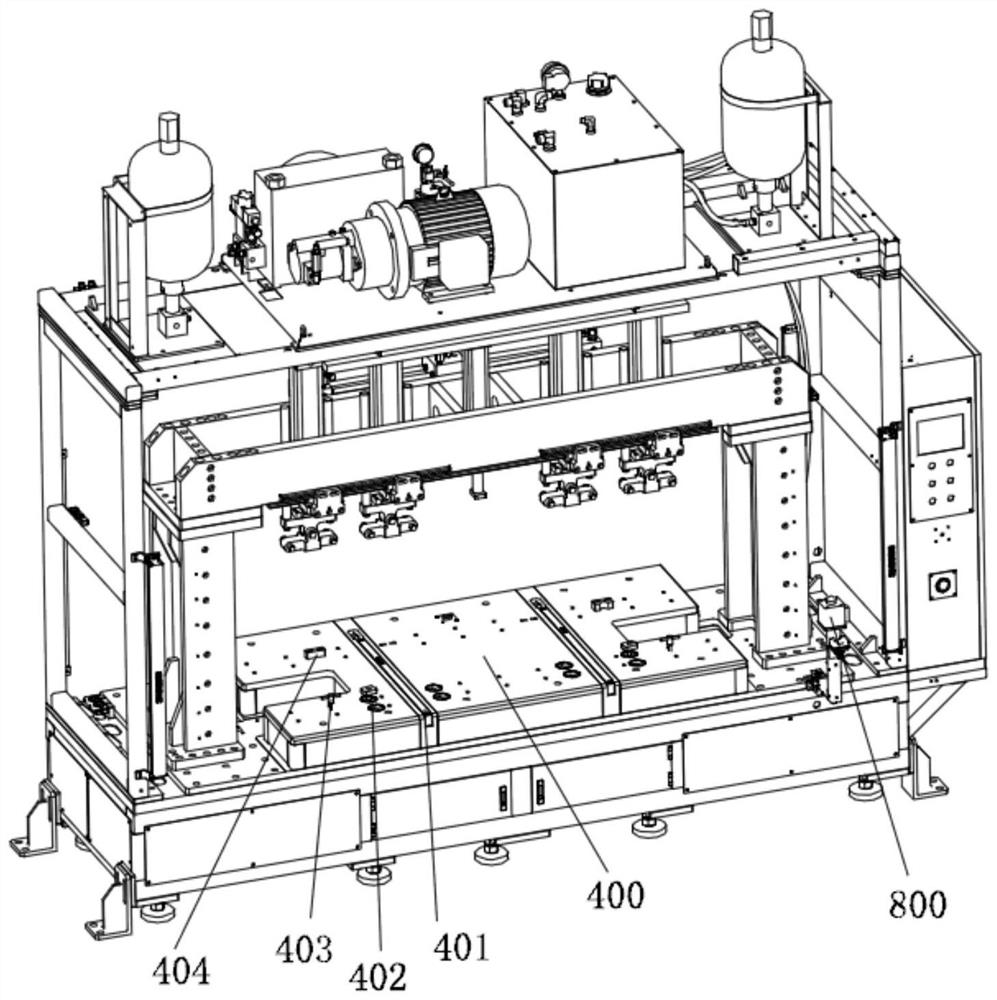

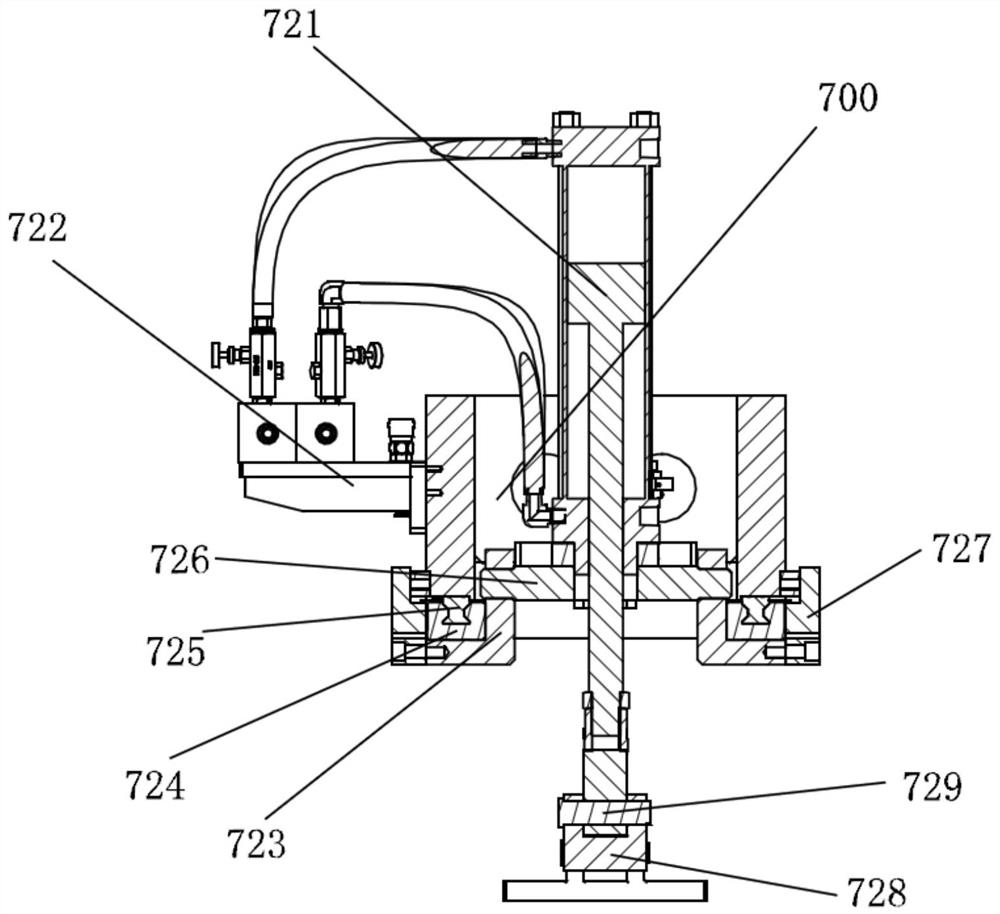

[0021] A specific embodiment of a kind of automobile water cutting and bending equipment described in this technical solution, its specific embodiment is as follows figure 1 - As shown in -4, it includes an underframe 100, a tooling placement platform 400 and a side bearing frame 500. The middle part of the upper end surface of the underframe 100 is provided with a tooling placement platform 400, and both sides of the tooling p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap