Aluminum plate forward and reverse bending device

A technology of bending device and aluminum plate, applied in storage device, feeding device, positioning device, etc., can solve the problems of low bending efficiency, waste products, large errors, etc., and achieve the effect of low reject rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing.

[0036] Depend on figure 1 It can be seen that the front and rear bending angles of the aluminum plate bent by the device of the present invention are preferably 30 degrees, and the bending width is 5 mm.

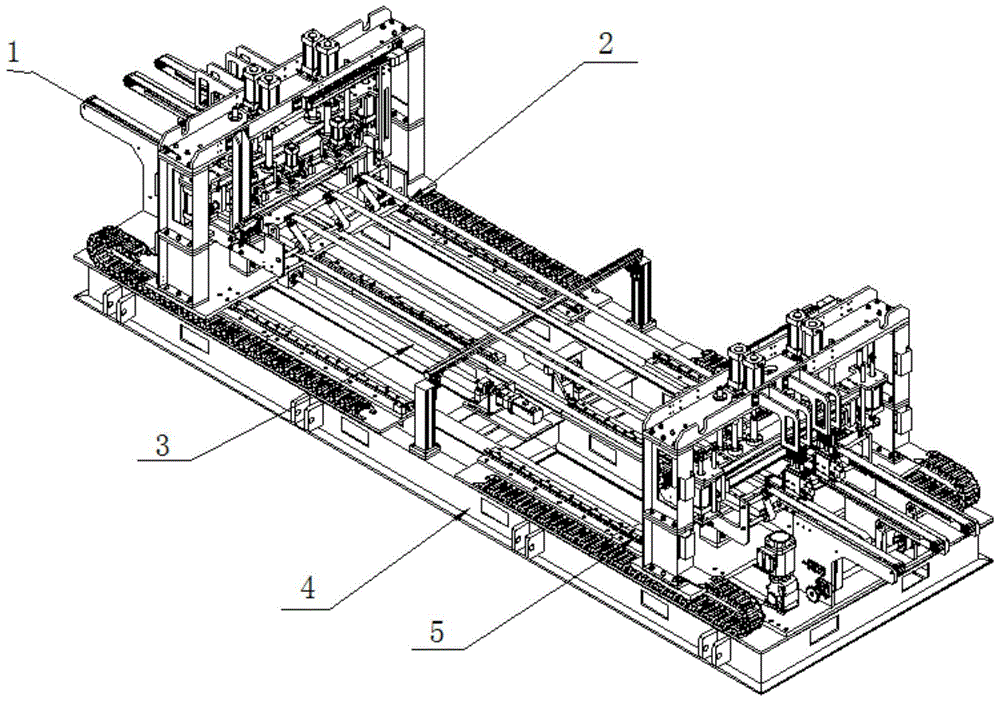

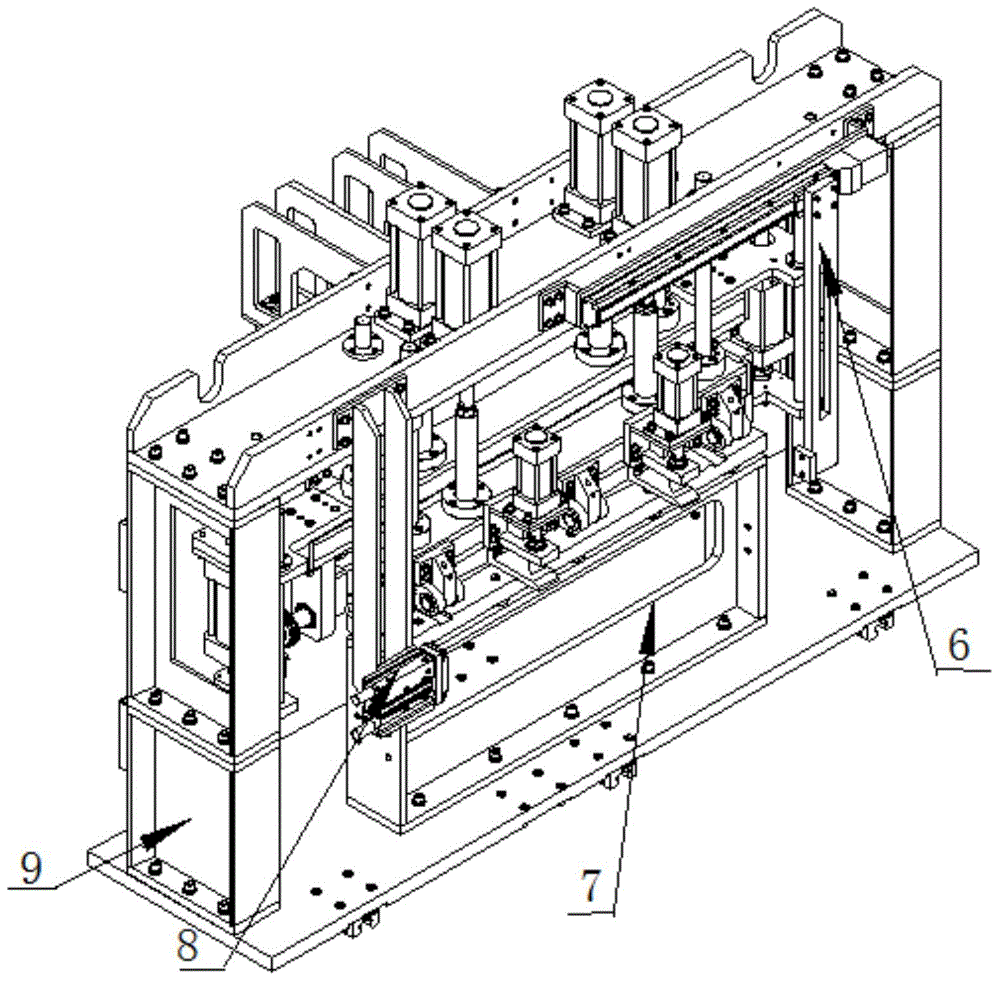

[0037] Depend on figure 2 It can be seen that a front and back bending device for aluminum plates includes a bending knife module 1, a belt conveying module 2, a servo moving module 3 and a base 4, wherein the bending knife module 2 includes bending knife modules installed on the left and right ends of the upper surface of the base respectively. The first bending knife part and the second bending knife part, the belt conveying module 2 is located between the two parts of the bending knife module 1, and the servo moving module 3 includes the first bending knife part and the second bending knife part respectively. The two parts connected by the bending knife part, the fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap