Reversing control method, driving force control unit, control system, method, and vehicle

A technology of control system and control unit, which is applied to control drive, vehicle components, electric vehicles, etc., can solve the problems of driver inconvenience, lack of auxiliary power for reversing, and heavy weight, so as to increase driving comfort, prevent hidden dangers of accidents, and ensure safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Preferred embodiments of the vehicle driving force control system and method thereof according to the present invention will be described in detail below with reference to the accompanying drawings.

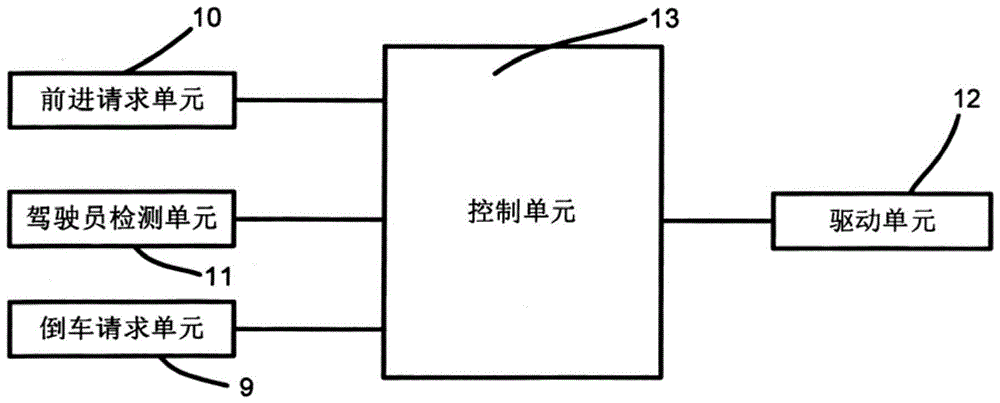

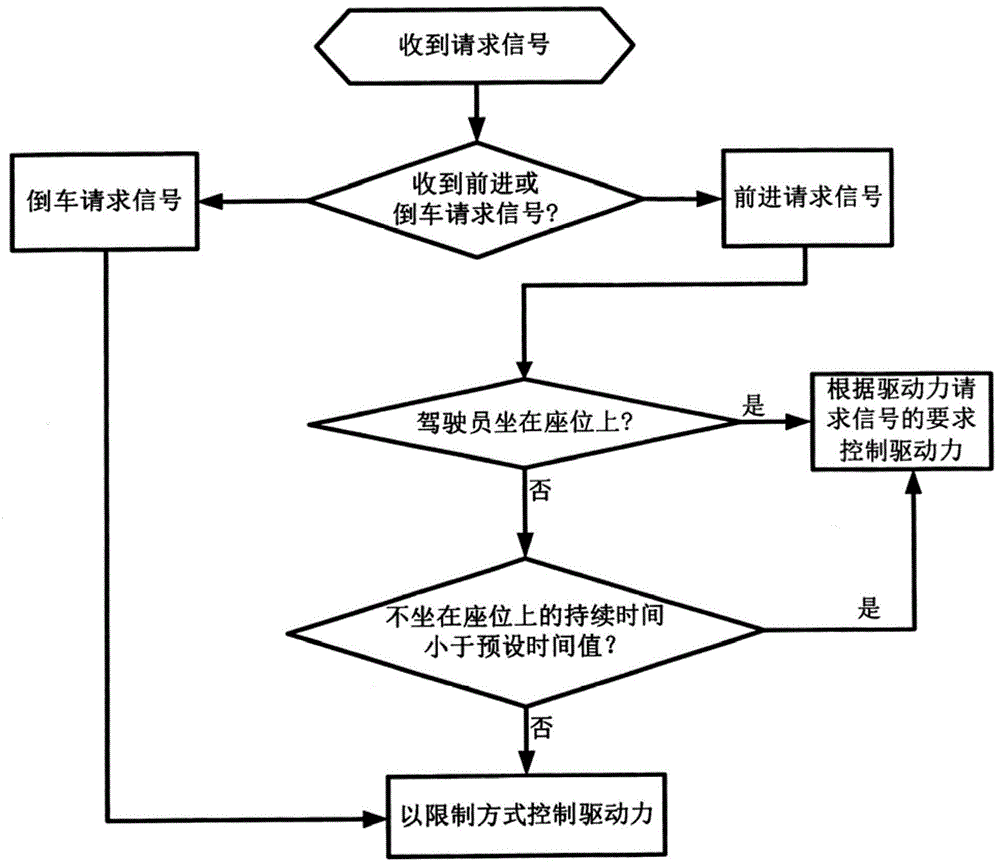

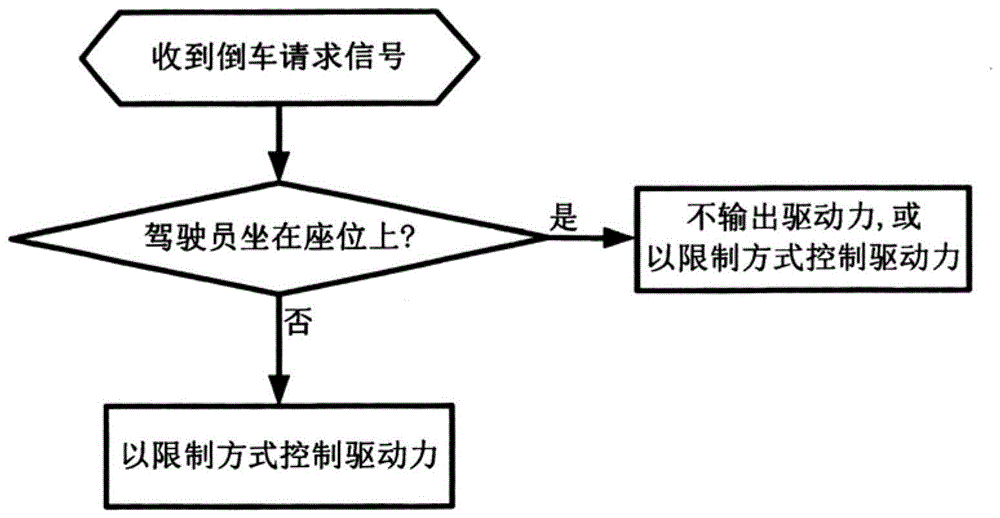

[0018] figure 1 It is a structural schematic diagram of a vehicle driving force control system according to an embodiment of the present invention. The vehicle drive force control system includes a forward request unit 10 , a reverse request unit 9 , a driver detection unit 11 , a drive unit 12 , and a control unit 13 . The control unit 13 includes an input terminal and an output terminal, the input terminal is connected with the forward request unit 10 , the reverse request unit 9 and the driver detection unit 11 , and the output terminal is connected with the drive unit 12 . The control unit 13 controls the magnitude and direction of the output drive force of the drive unit 12 according to the signals of the forward request unit 10 , the reverse request unit 9 and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com