A shock-absorbing adjustment mechanism for a plane mirror

A technology of adjusting mechanism and plane mirror, applied in installation, optics, instruments, etc., can solve the problems of plane mirror deformation, high cost, inability to meet the requirements of use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

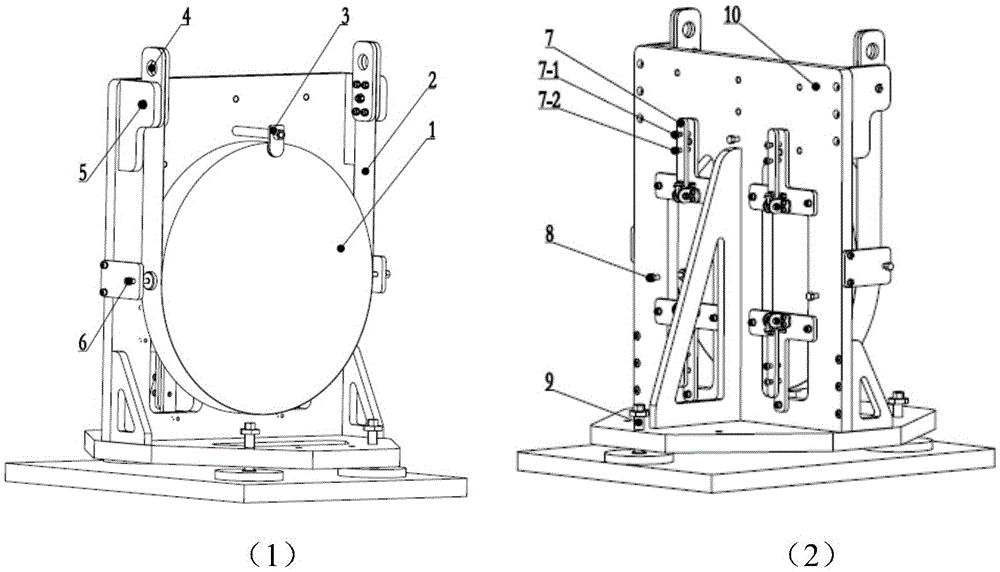

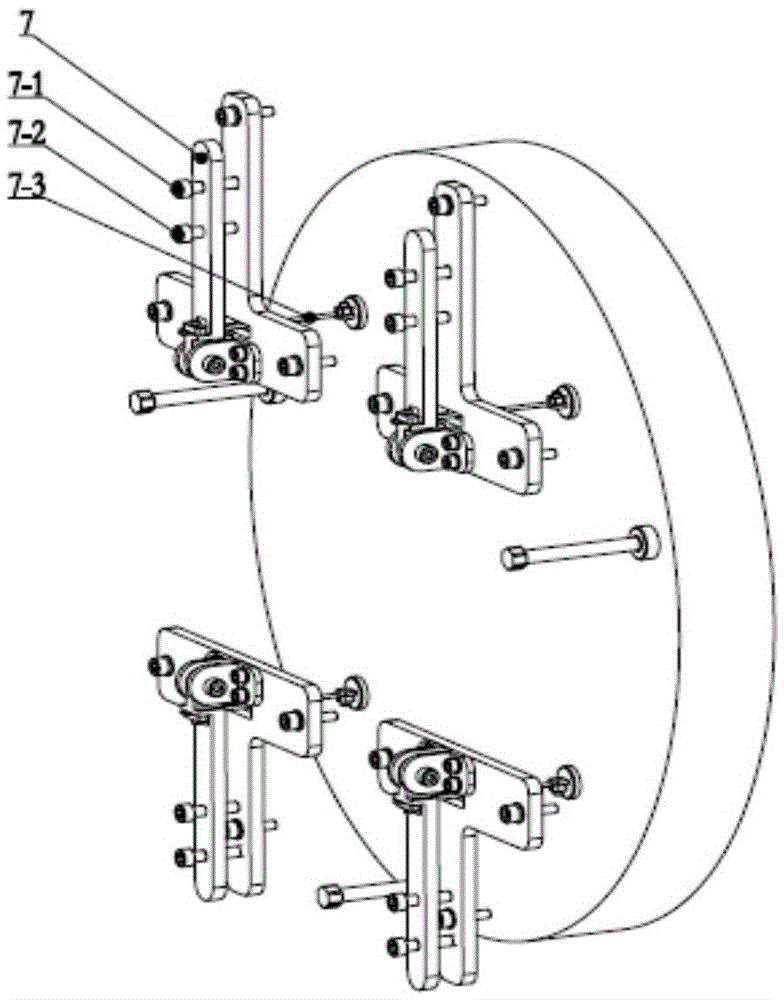

[0019] exist figure 1 In the shown embodiment, a microcrystalline plane mirror 1 with a diameter of 600 mm is placed on a thin steel strip 2 with a thickness of 0.5 mm, and is hung on the main structure 10 through a suspension block 4 and a half-threaded bolt 5 of M14, and the lateral screw adjustment is adjusted. Rod 6 withstands both sides of plane mirror 1, loosen adjustment screw rod 7-1 and tension adjustment screw rod 7-2 in combination to make tension steel belt 7-3 pull plane mirror 1, and adjust back thread adjustment rod 8 to withstand plane mirror 1, Adjust the bottom threaded adjustment rod 9 to realize the adjustment of the plane mirror 1 up and down and pitch direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com