Patents

Literature

33results about How to "Fast steady state" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

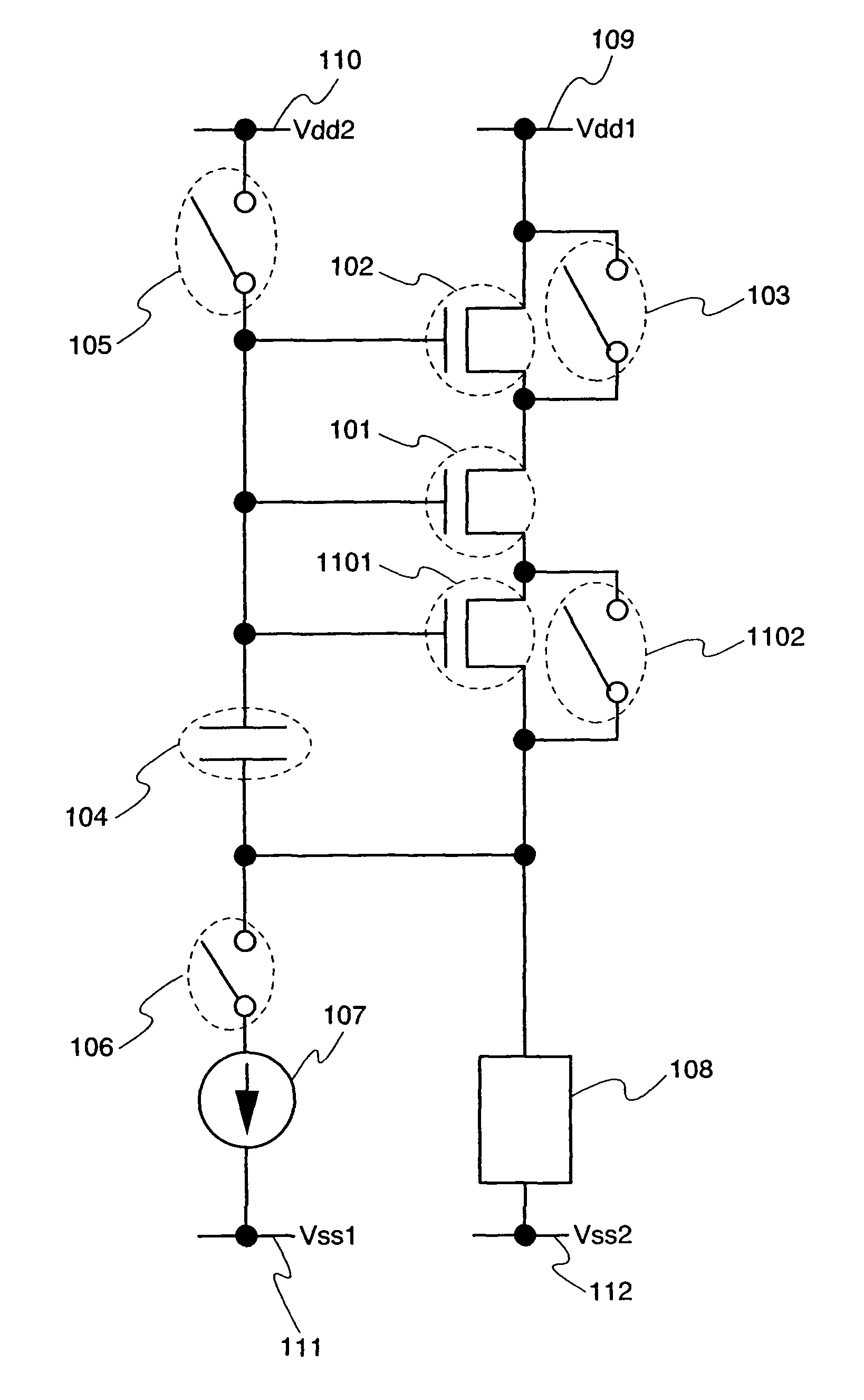

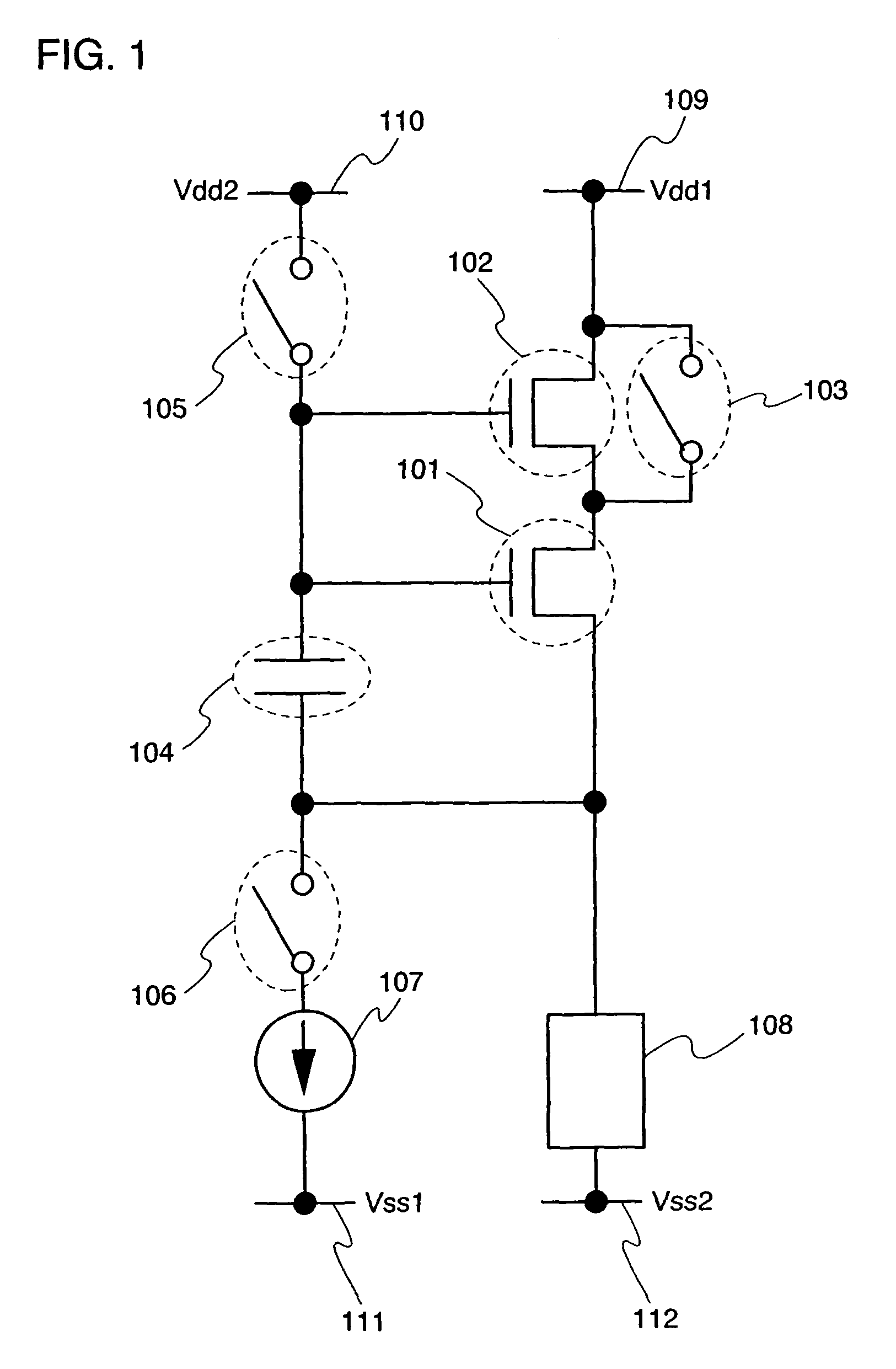

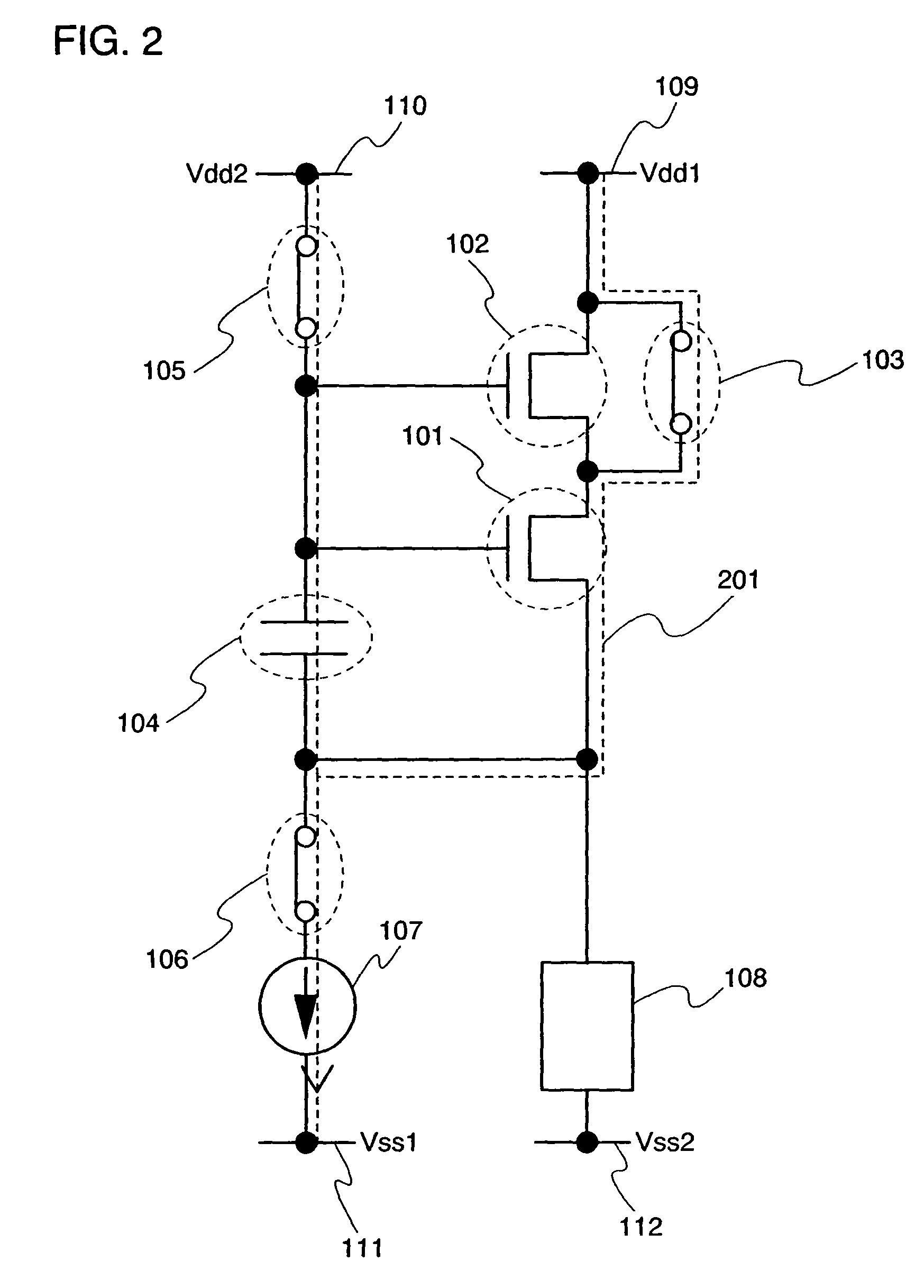

Semiconductor device, display device and electronic device equipped with the semiconductor device

InactiveUS20070035340A1Reduce power consumptionAvoid flowImpedence convertorsElectroluminescent light sourcesCapacitanceElectrical resistance and conductance

The present invention provides a semiconductor device which can prevent a current from flowing into a display element at a signal writing operation, without increasing power consumption and without changing a potential of a power supply for supplying a current to a load in each row. When a predetermined current is supplied to a transistor to set a gate-source voltage of the transistor, a potential of a gate terminal of the transistor is adjusted so as to prevent a current from flowing into a load which is connected to a source terminal of the transistor. Thus, a potential of a wire connected to the gate terminal of the transistor is made different from that of a wire connected to a drain terminal of the transistor. At that time, an operation of a transistor is shifted so as to allow a large amount of current to flow, and influences by intersection capacitance parasitic to a wire or the like or wire resistance are hardly caused, and a set operation is conducted quickly.

Owner:SEMICON ENERGY LAB CO LTD

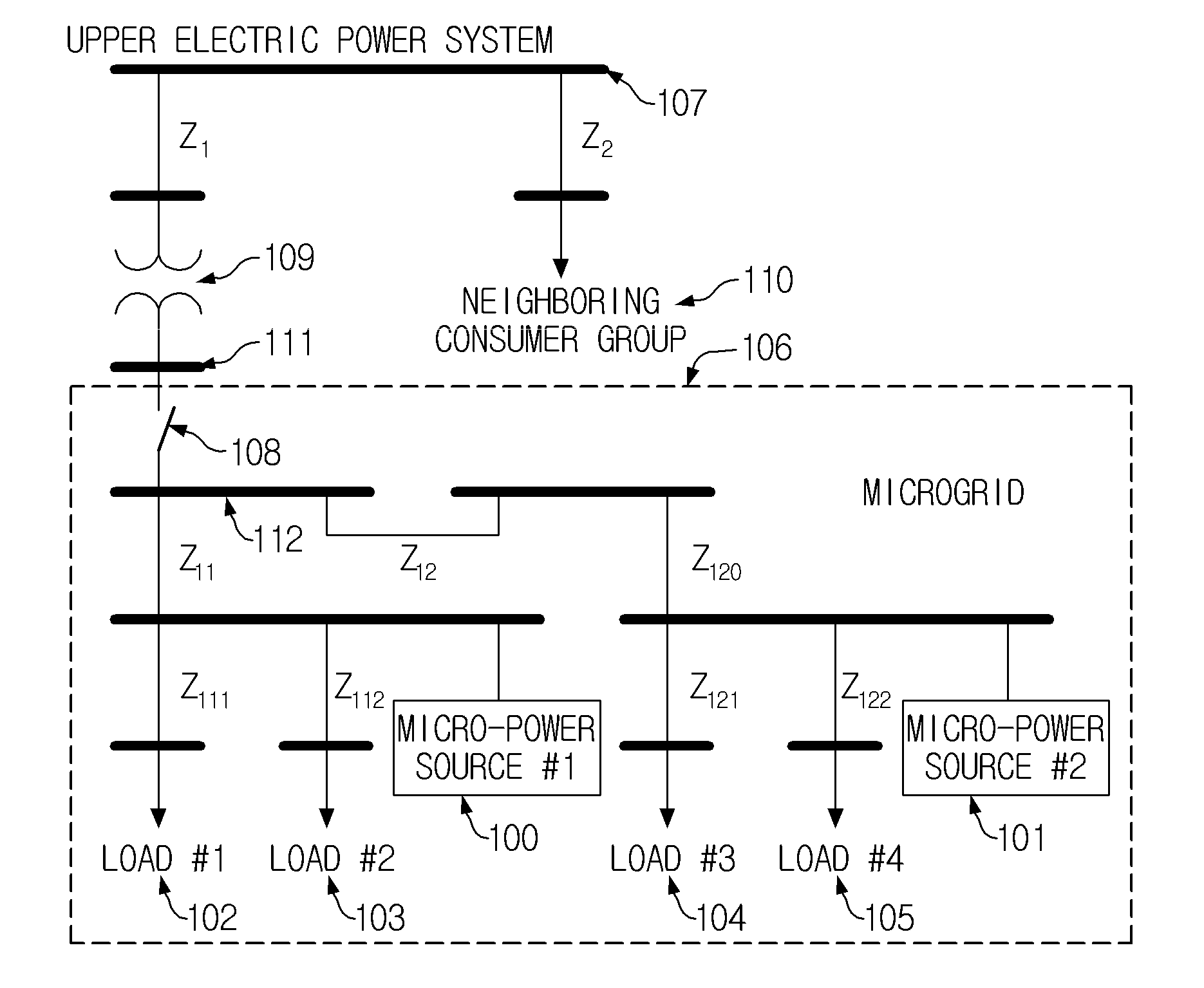

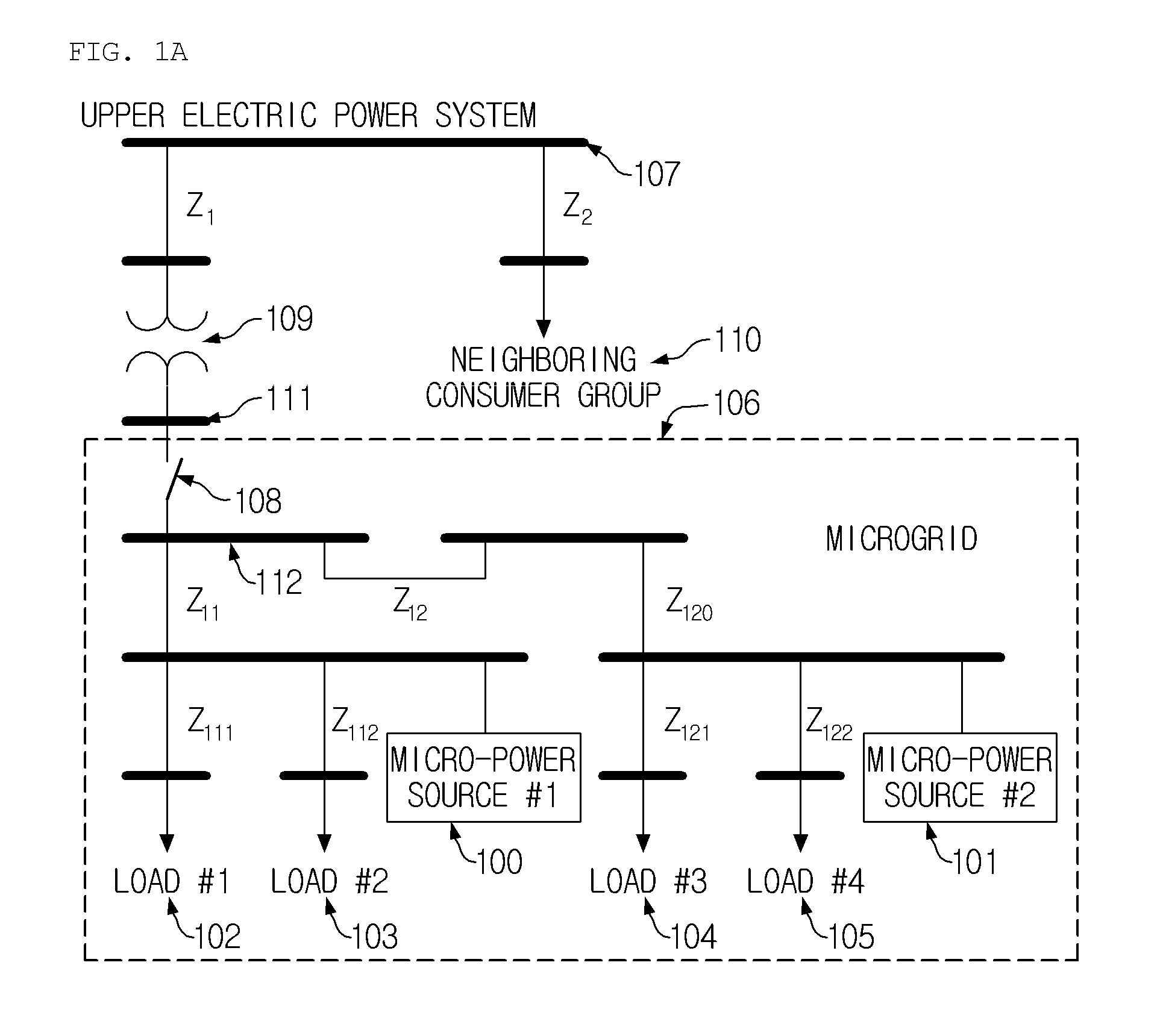

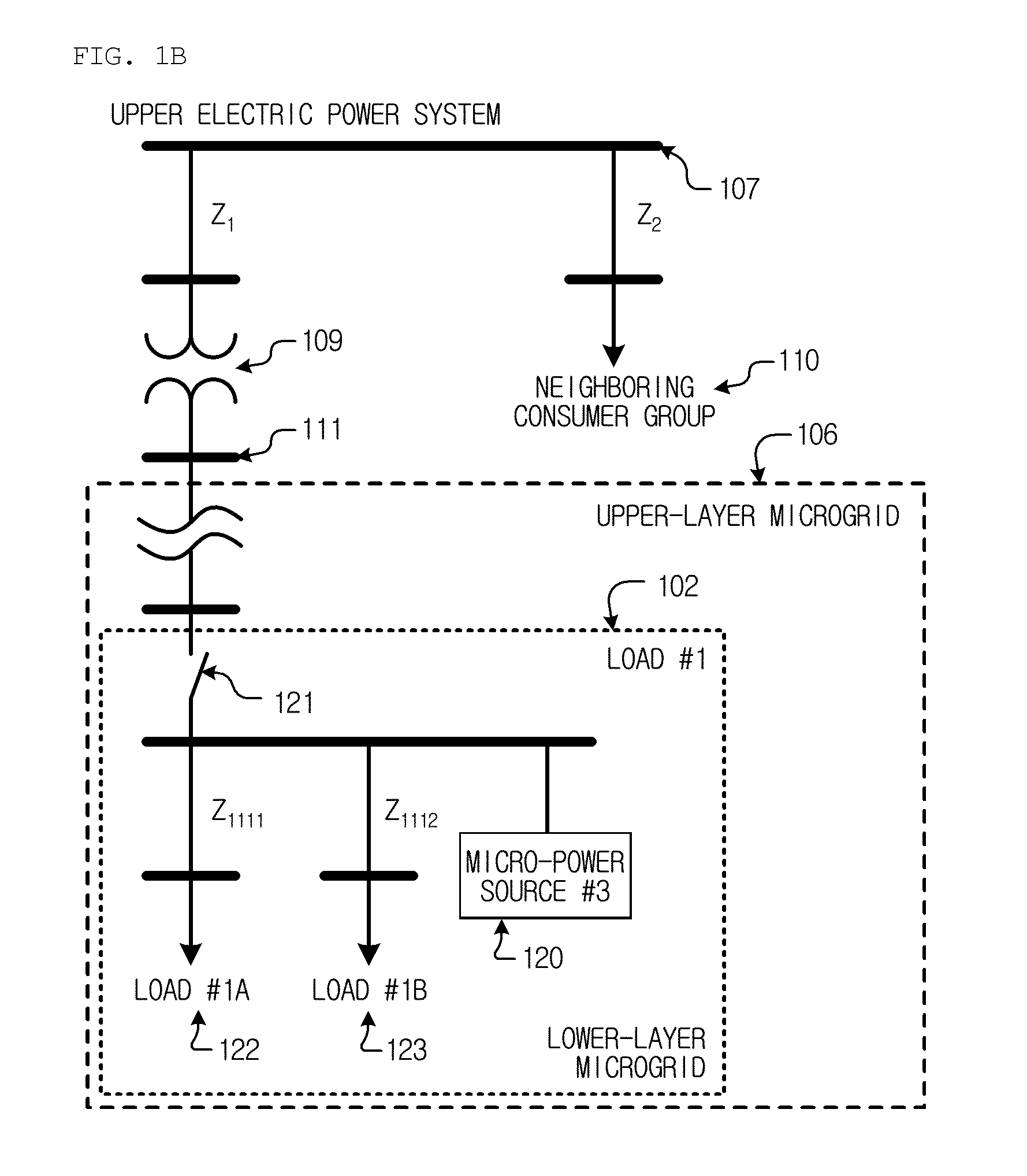

Apparatus and control method of micro-power source for microgrid application

InactiveUS20110248569A1Rapidly reach steady stateSmooth switchingDc network circuit arrangementsEnergy industryPower qualityMicrogrid

The present invention relates to a micro-power source for successfully implementing a microgrid and to a control method for realizing smooth reconnection between the microgrid and an upper electric power system and smooth switching between the control modes of the micro-power source. A micro-power source sectionalizes an electric power system into an upper electric power system and a lower electric power system, and enables the lower electric power system to be independently operated in an island mode and to smoothly switch between a grid-connected mode and the island mode. As a result, a hierarchical microgrid is implemented with sectionalized sub-microgrids. One of the merits of the hierarchical microgrid is that each consumer group can be supplied with high quality power regardless of the power quality of the other consumer groups, and various types of services independently.

Owner:GRIDON

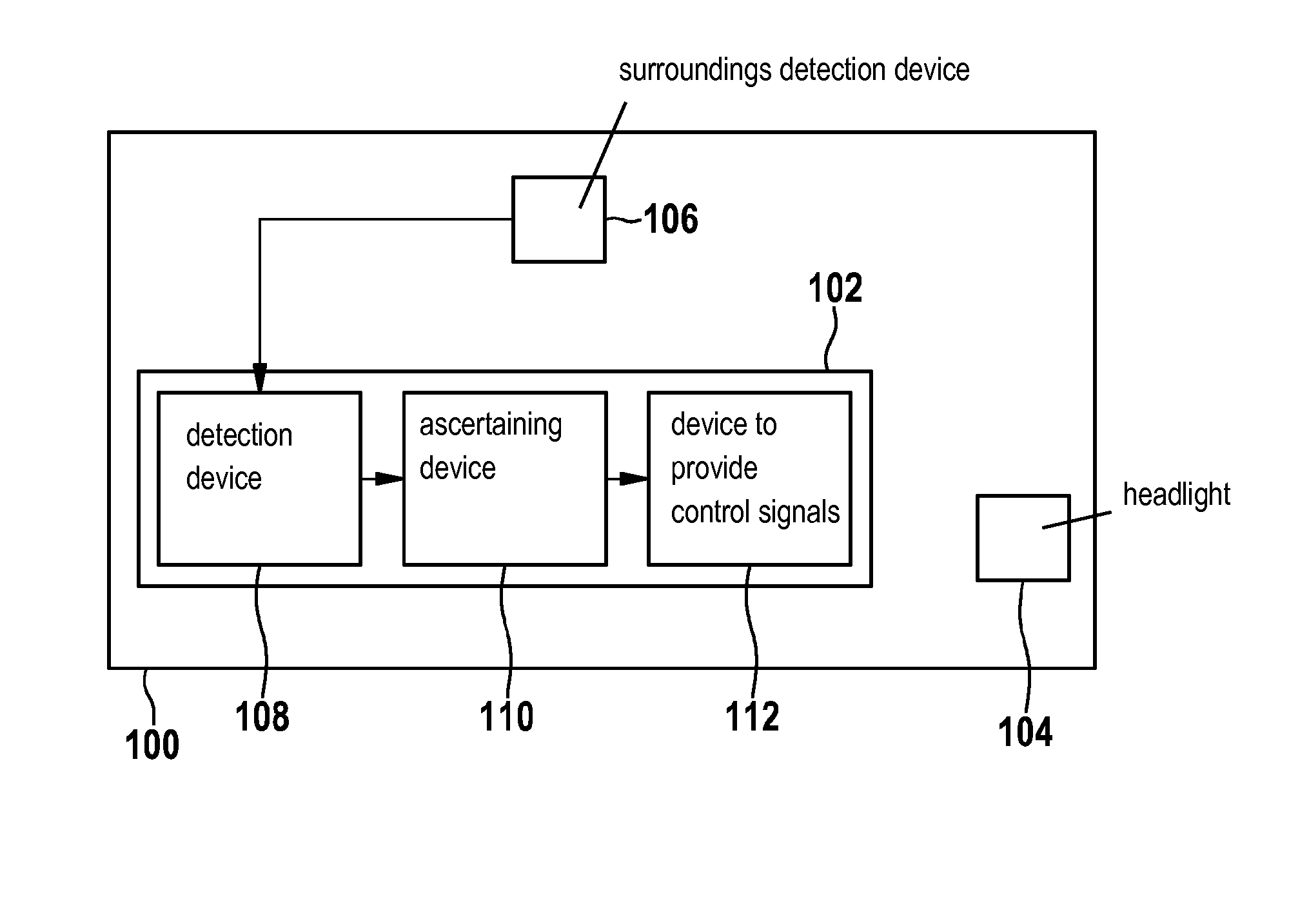

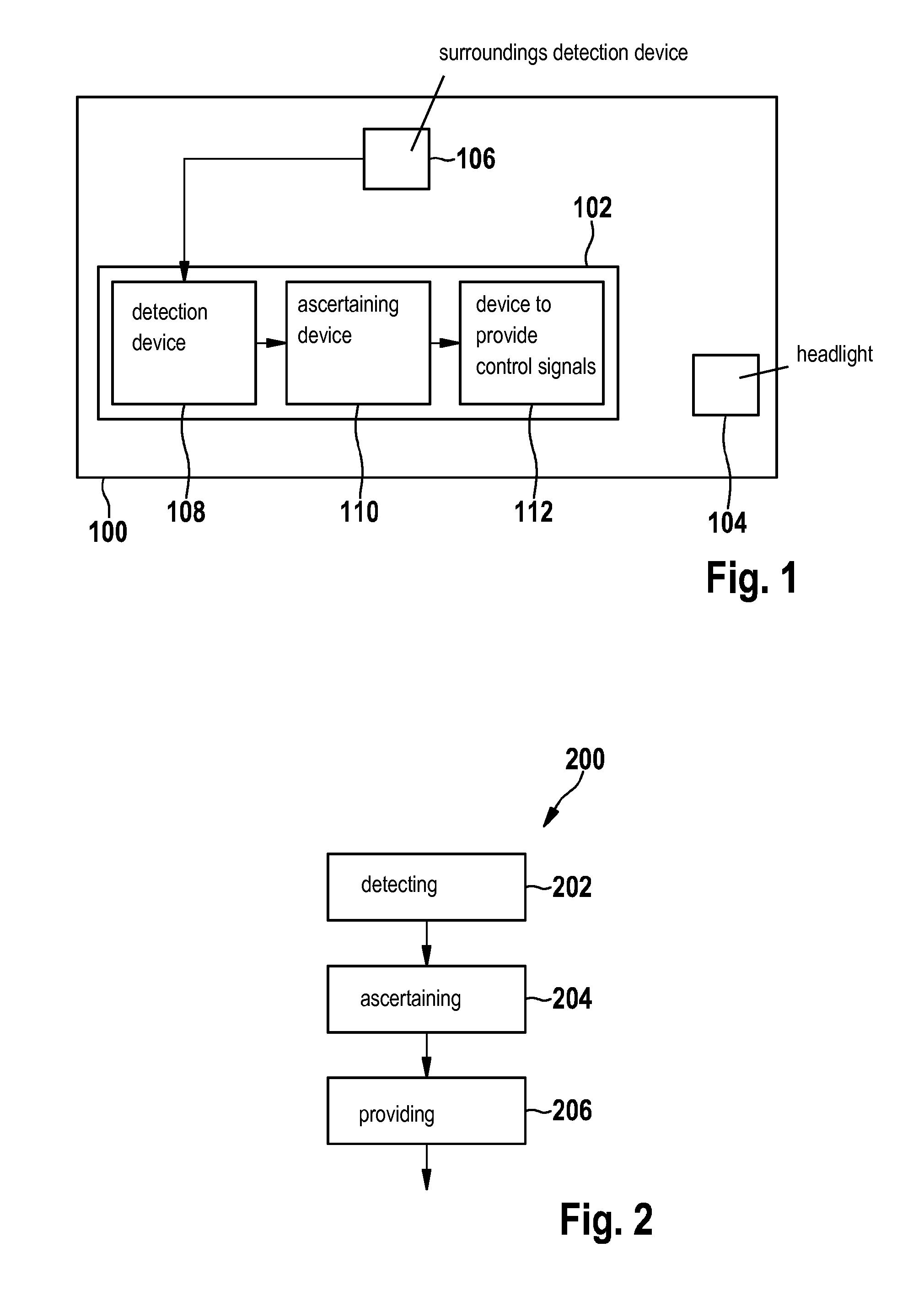

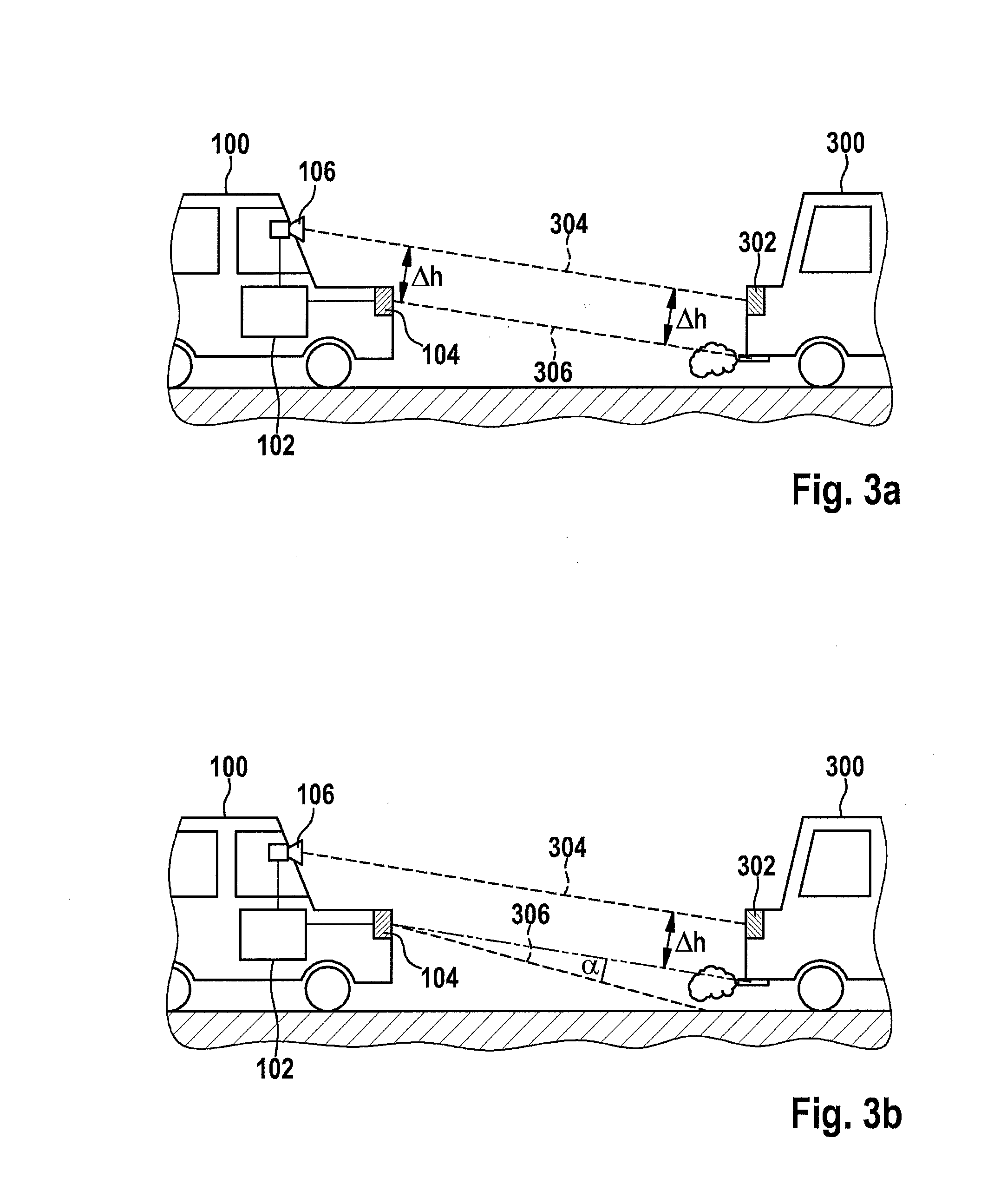

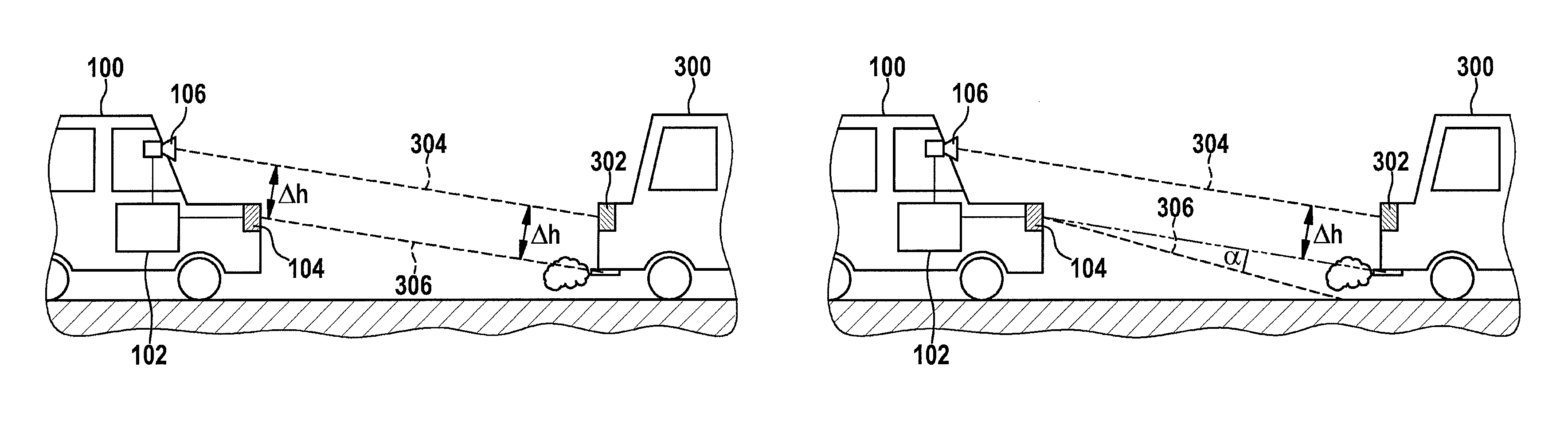

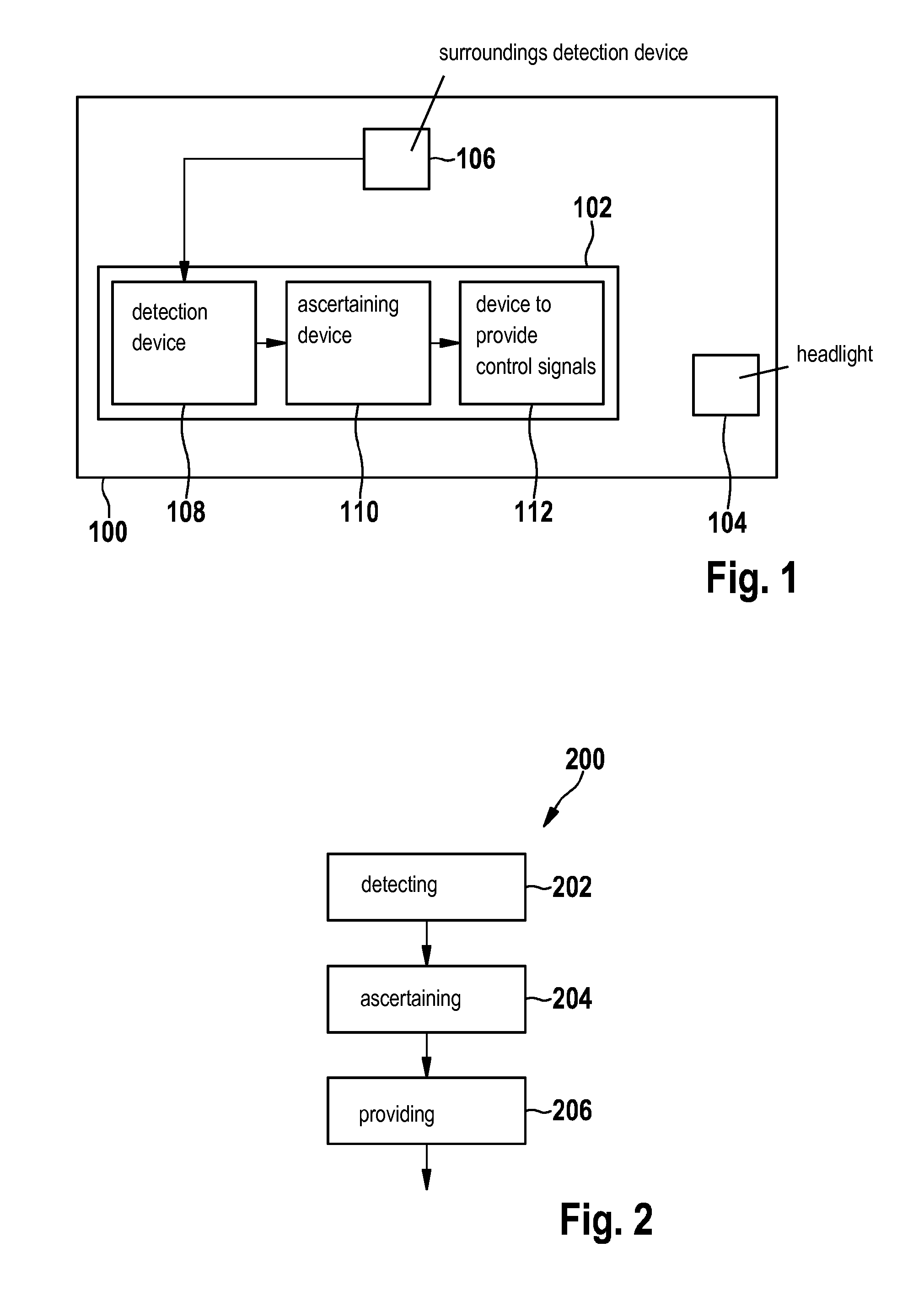

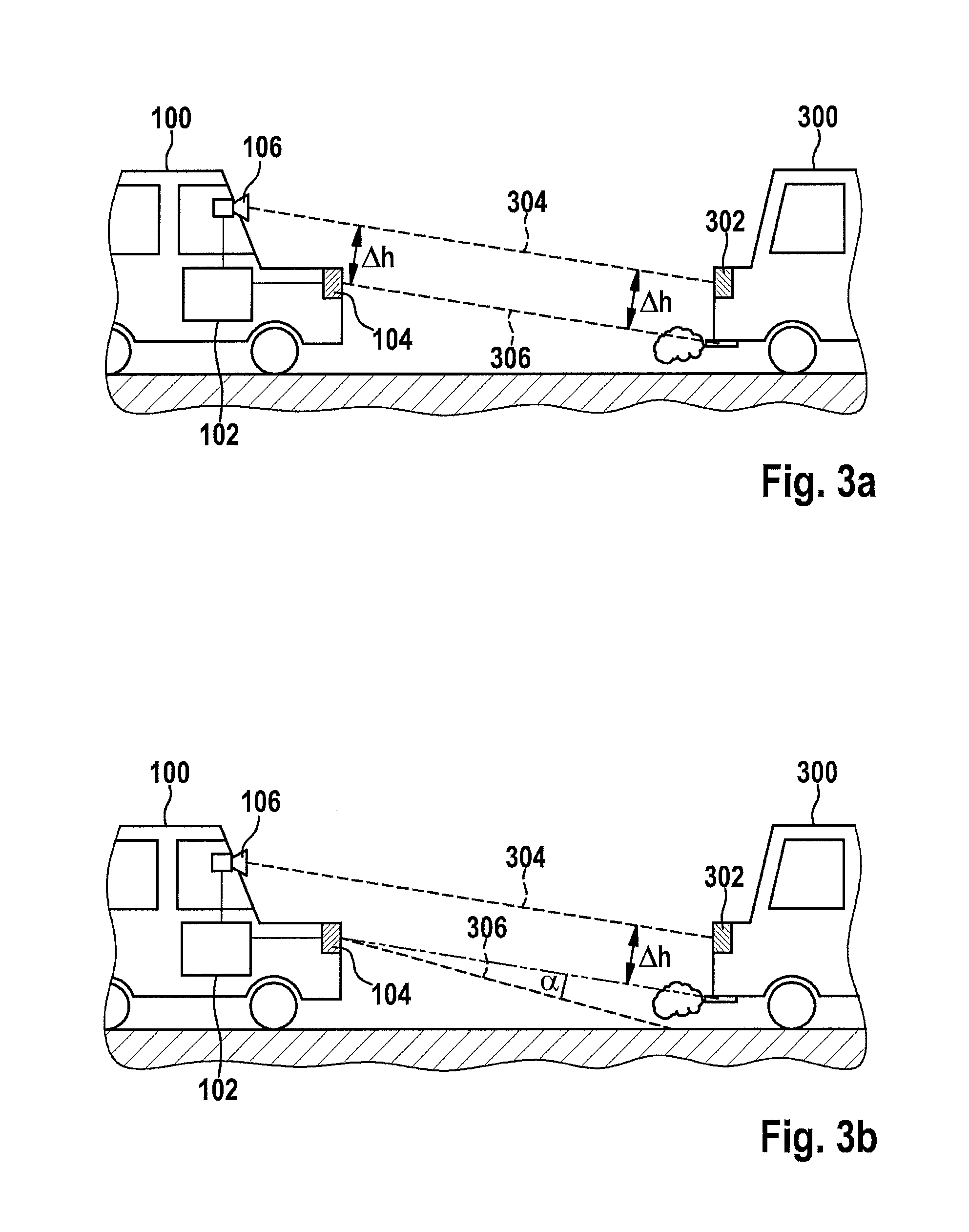

Method and control unit for adapting an upper headlight beam boundary of a light cone

ActiveUS20150051797A1Increase probabilitySafety value may also become smallVehicle headlampsDigital data processing detailsControl signalRoll rate

A method for adapting an upper headlight beam boundary of a light cone of at least one headlight of a vehicle. The method includes detecting a time curve of a pitch rate of the vehicle or a value that is dependent on the pitch rate and / or of a roll rate of the vehicle or a value that is dependent on the roll rate. The method also includes ascertaining an envelope curve and / or an amplitude of the time curve and / or an average value of the time curve. The method also includes providing a control signal for adapting the upper headlight beam boundary of the headlight beam.

Owner:ROBERT BOSCH GMBH

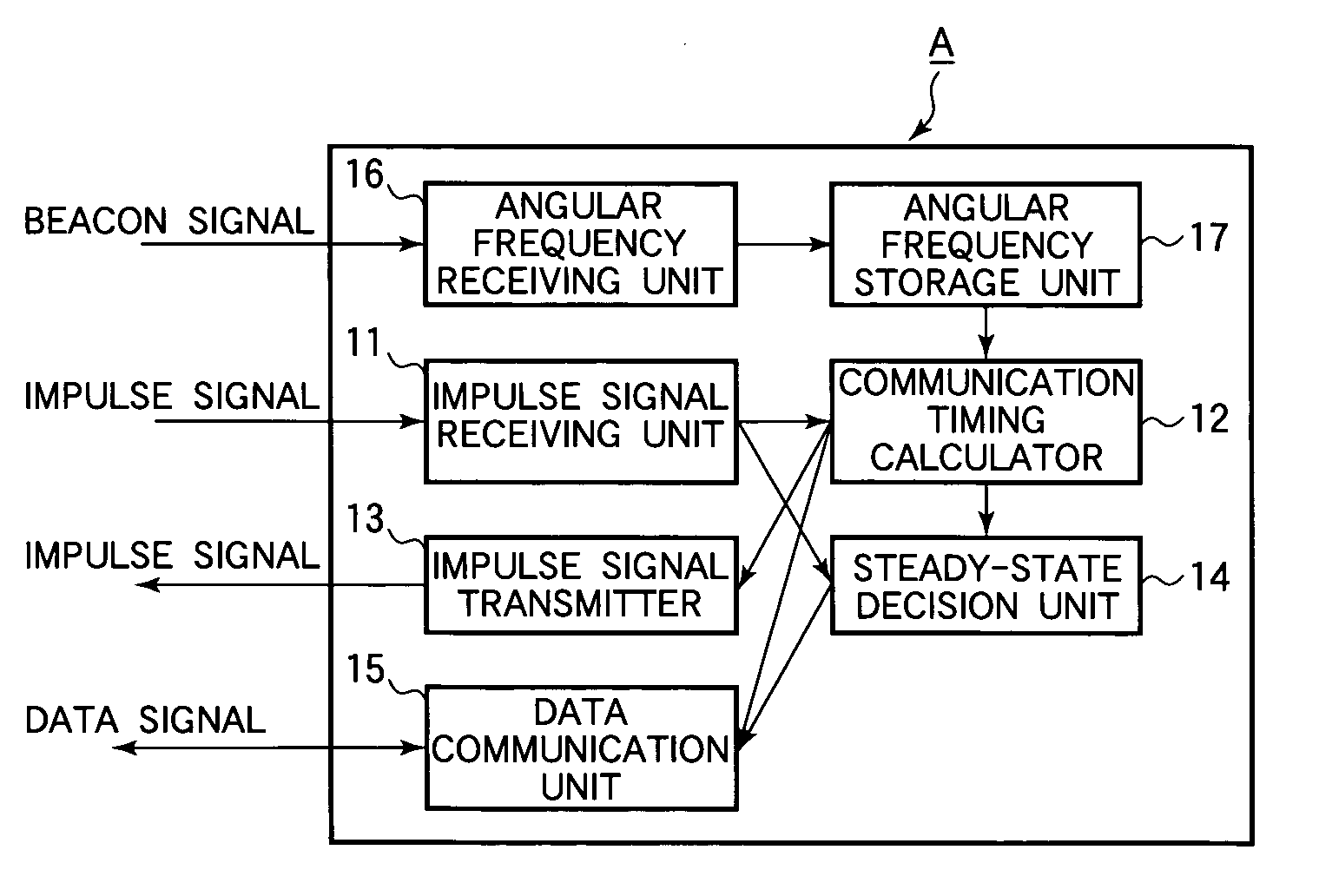

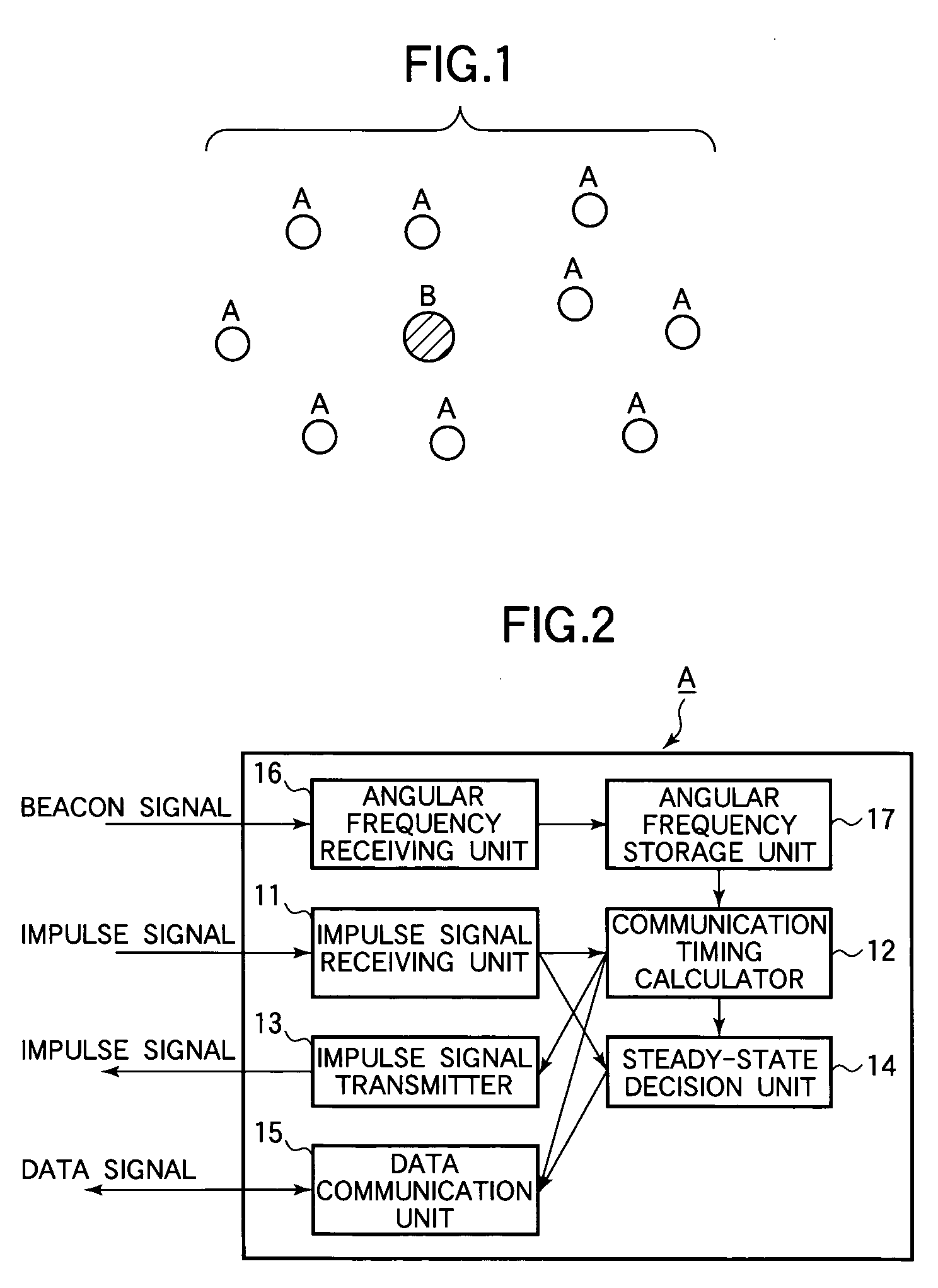

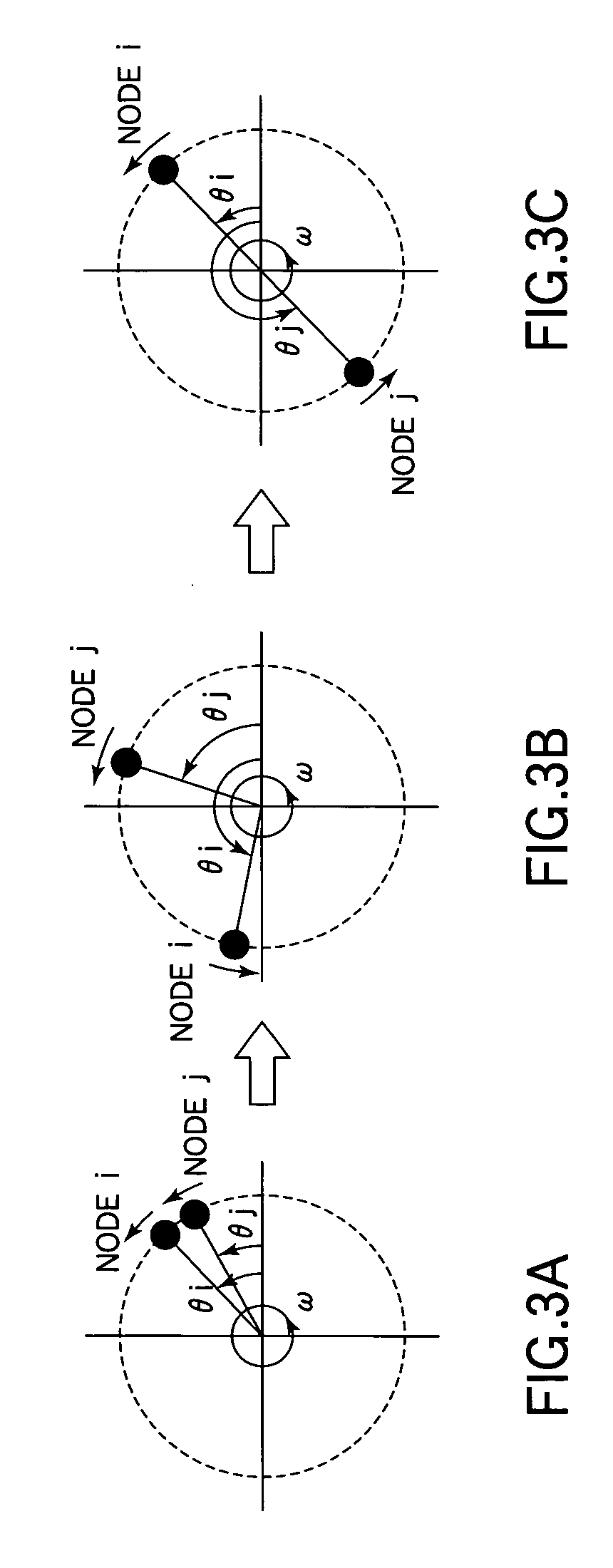

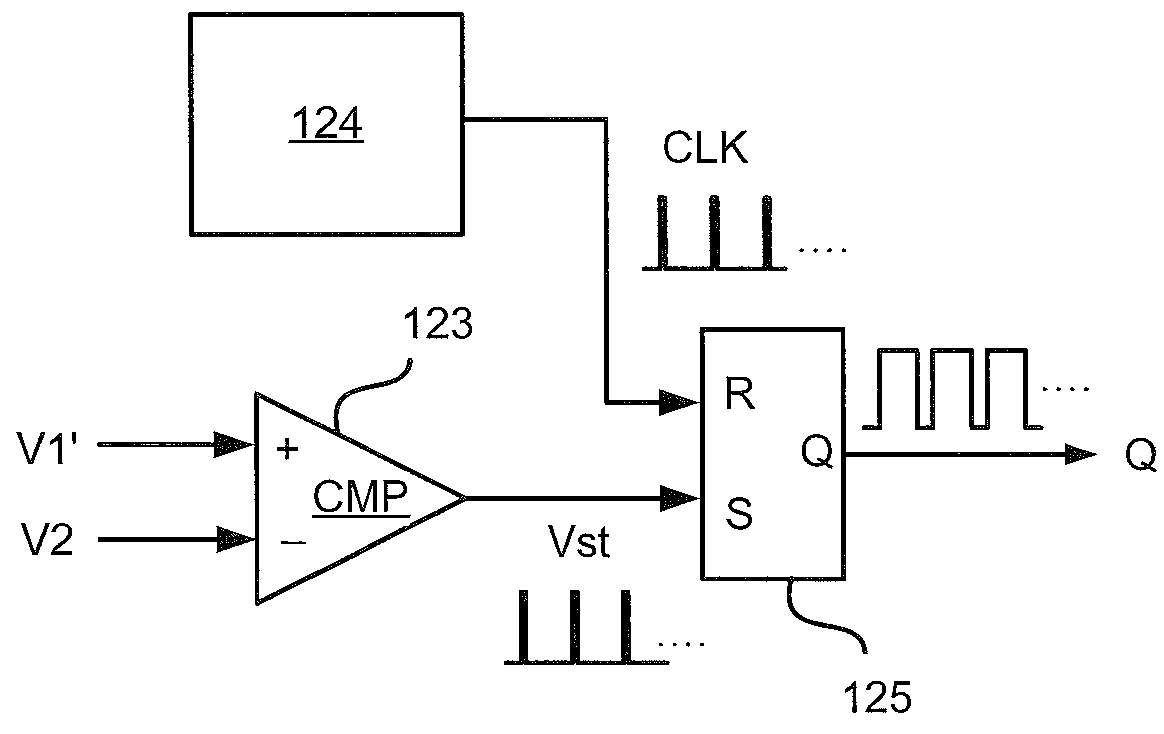

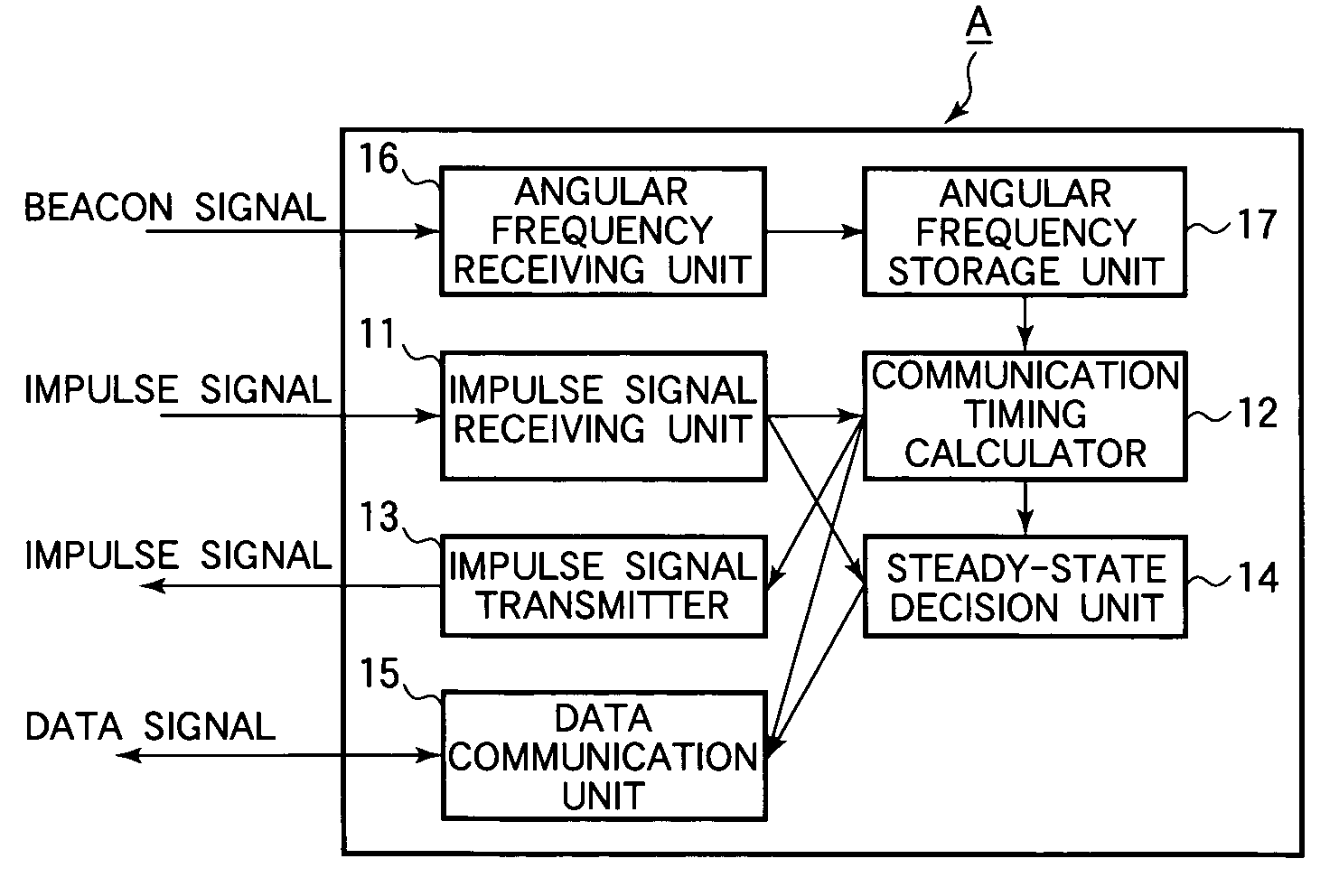

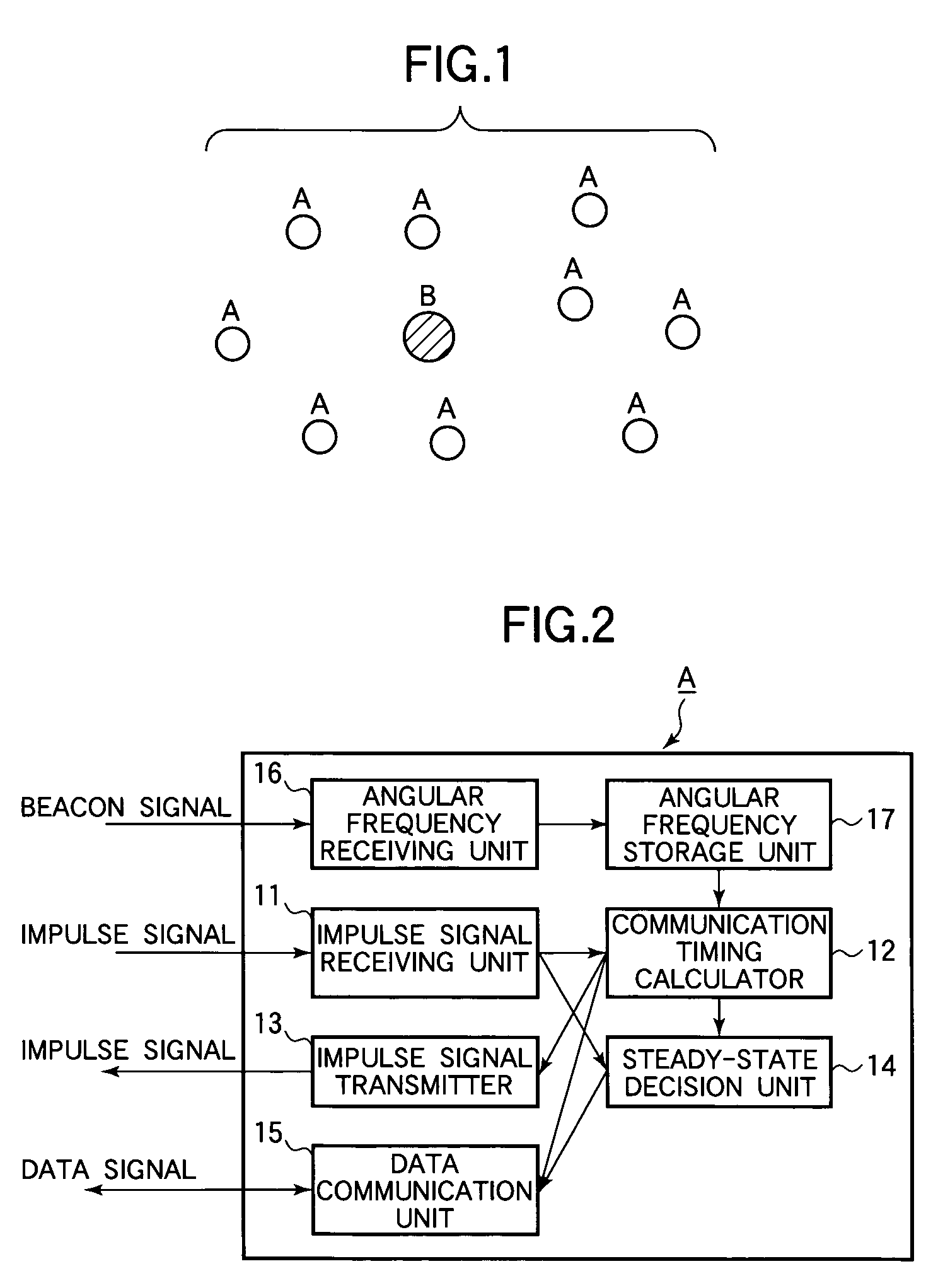

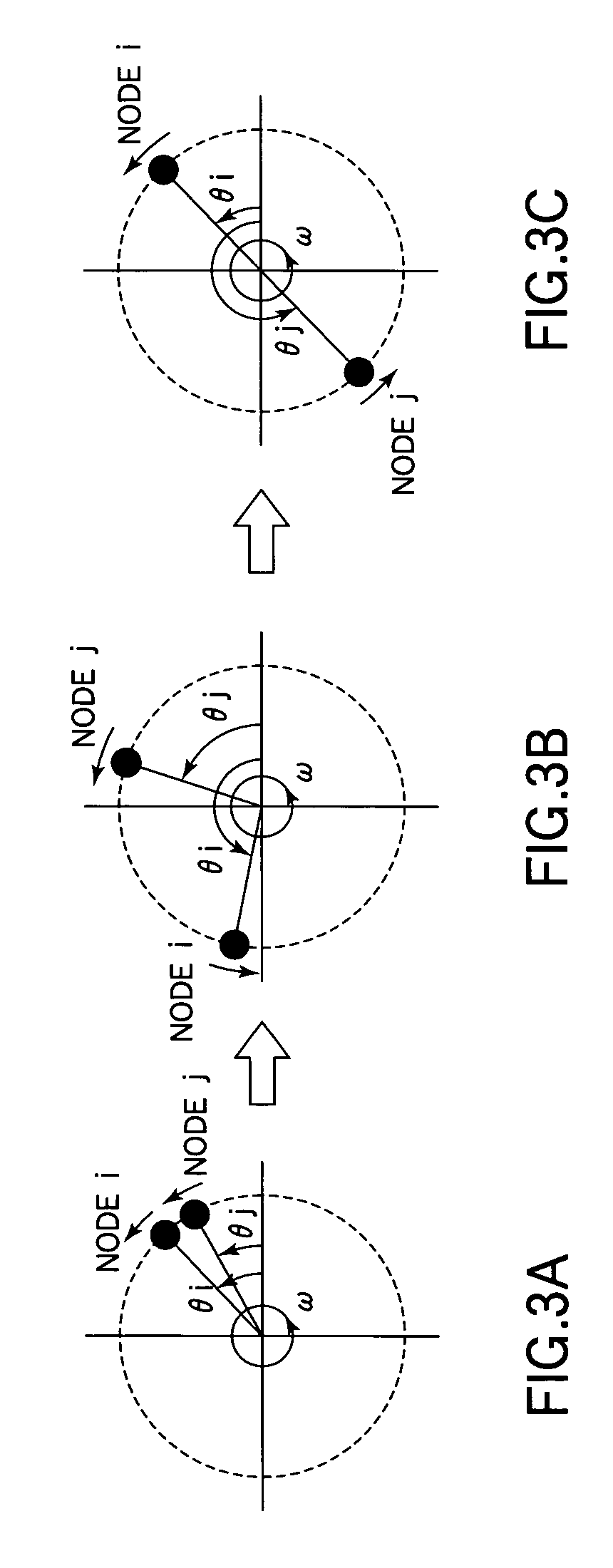

Communication timing control method and apparatus, node, and communication system

InactiveUS20050195771A1Avoid Signal ConflictsFast steady stateSynchronisation arrangementTime-division multiplexCommunications systemCommunication unit

A communication timing control apparatus for use in the nodes of a communication system includes a signal communication unit that transmits a state variable signal to neighboring nodes and receives state variable signals from those nodes. An external control signal, such as a beacon signal transmitted by a control node, is also received. The state variable signals indicate internal operating sates or timings of the nodes; the control signal indicates a basic transition rate. A timing decision unit causes internal state or timing transitions to occur at timings responsive to the basic transition rate and the received state variable signals, adjusting the transition timings so as to avoid signal collisions and to adapt to changing system conditions. Use of the control signal enables a steady timing state to be reached quickly.

Owner:OKI ELECTRIC IND CO LTD

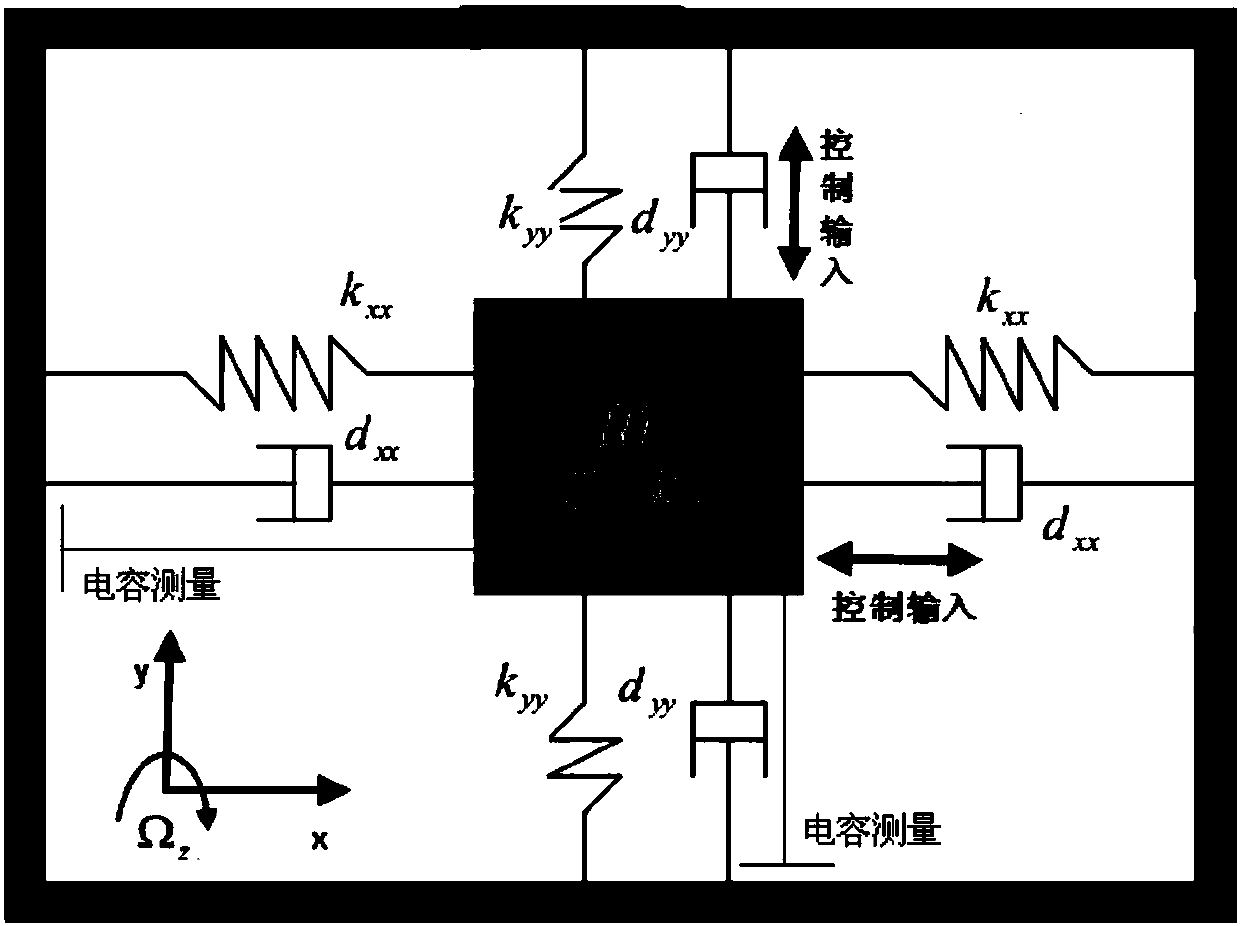

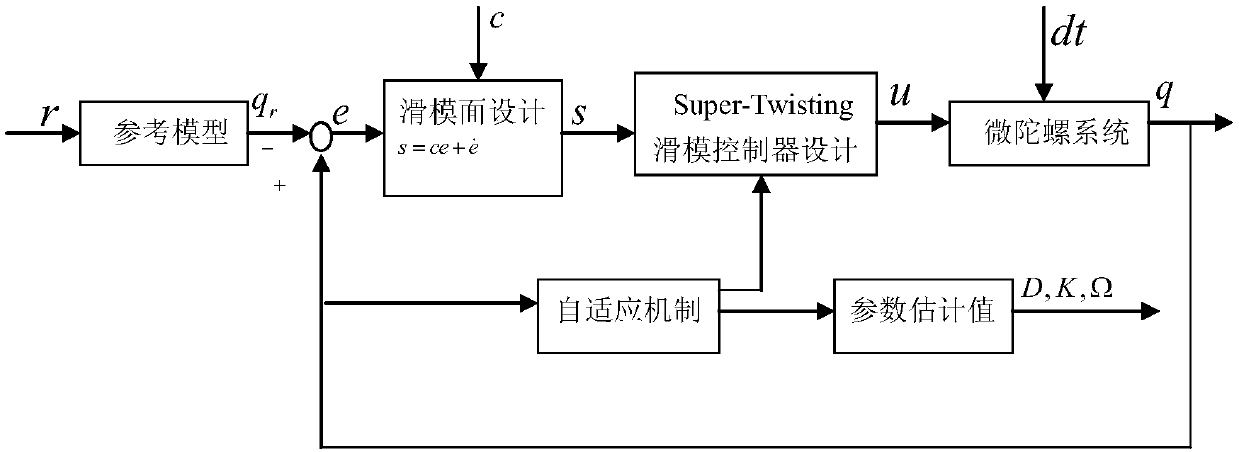

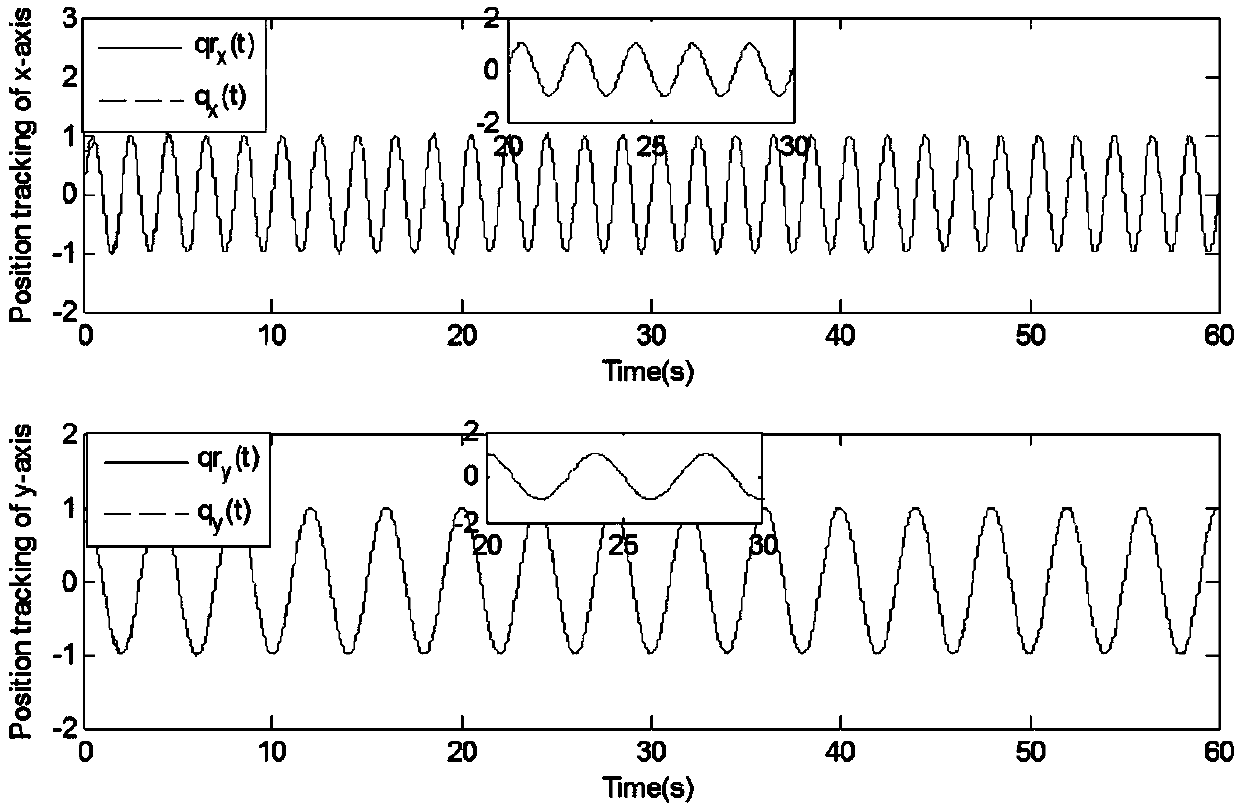

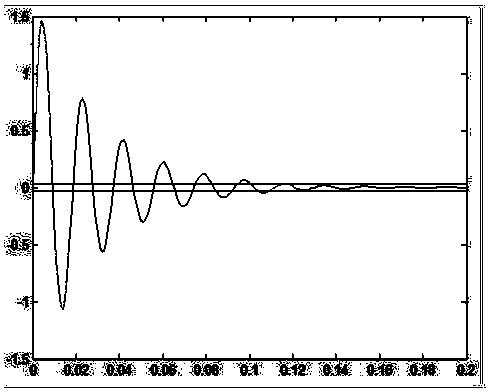

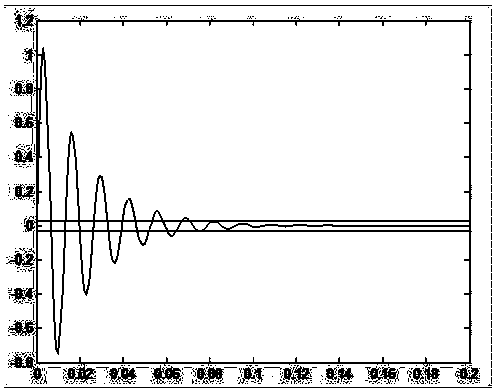

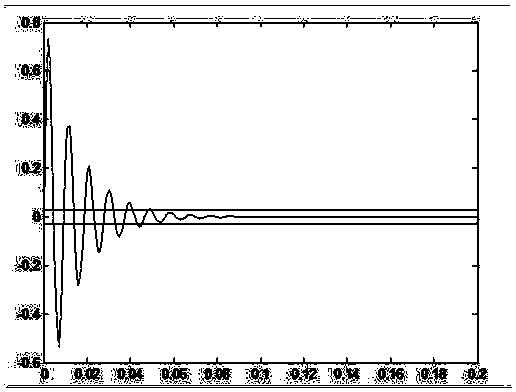

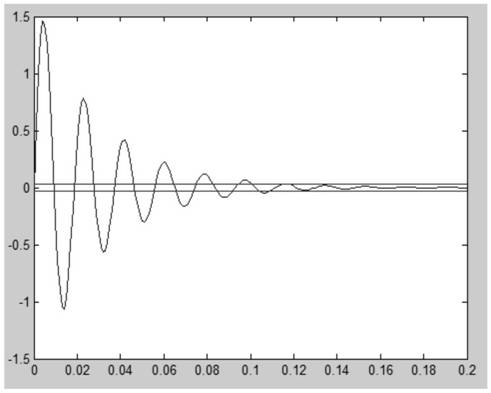

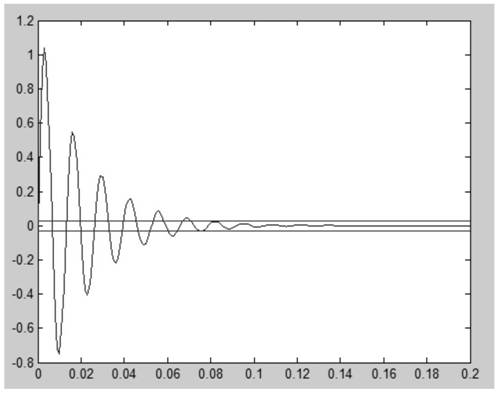

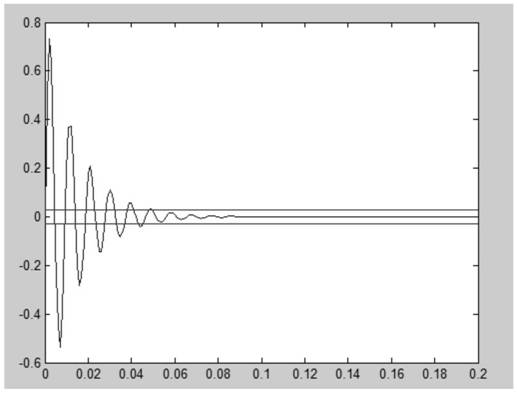

Micro gyroscope adaptive high-order super-twist slip form control method

InactiveCN107831660AFast and Accurate TrackingFast convergenceAdaptive controlGyroscopeLiapunov function

The present invention discloses a micro gyroscope adaptive high-order super-twist slip form control method. The micro gyroscope adaptive high-order super-twist slip form control method adopts a methodof combining the equivalent slip form control and the super-twist control to design an adaptive high-order super-twist slip form controller and design the adaptive laws of which the parameters are not determined of a micro gyroscope system, and then adopts an Lyapunov function to analyze the stability of the micro gyroscope system, thereby guaranteeing the asymptotic stability of the system. Themethod of the present invention combines the advantages that the high-order super-twist slip form control can effectively suppresses the buffeting, etc., controls to improve the performances of the system, enables the robustness of the micro gyroscope system to the indeterminacy and the external interference to be improved, and guarantees the stability of the system.

Owner:HOHAI UNIV CHANGZHOU

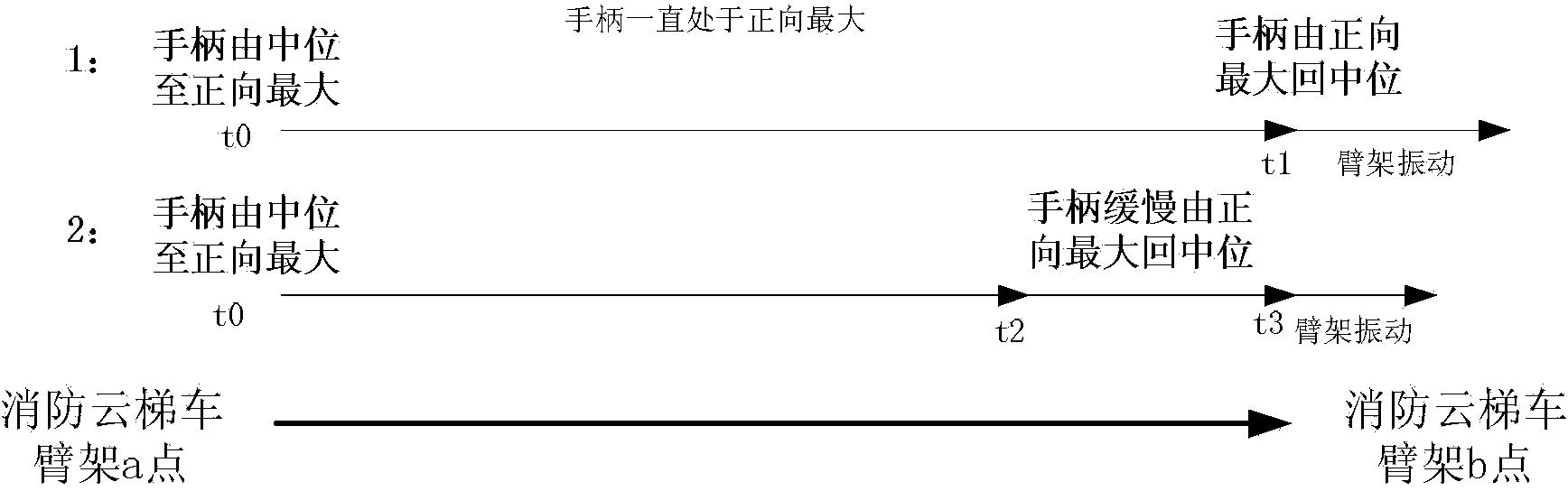

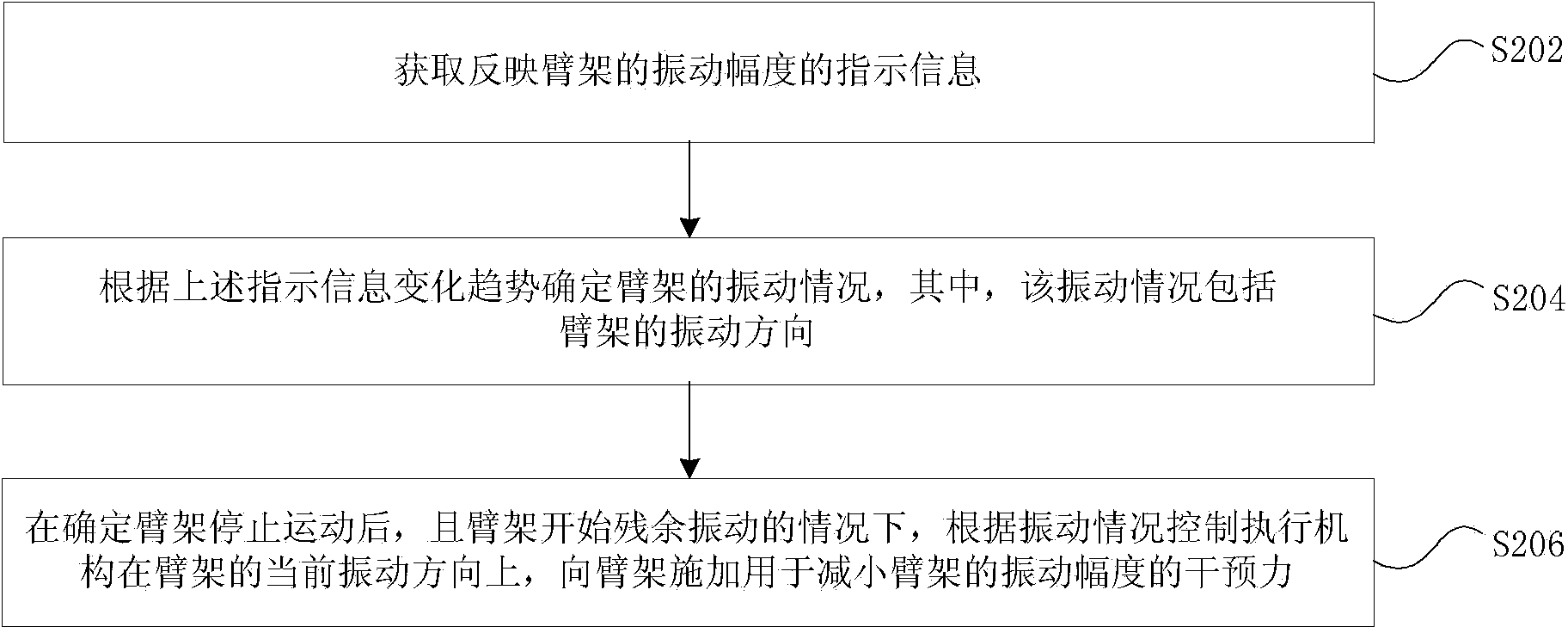

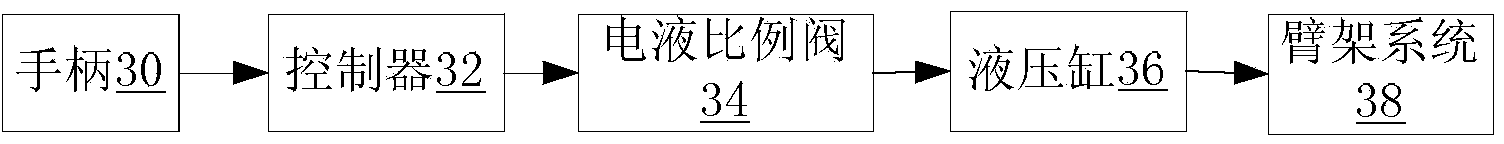

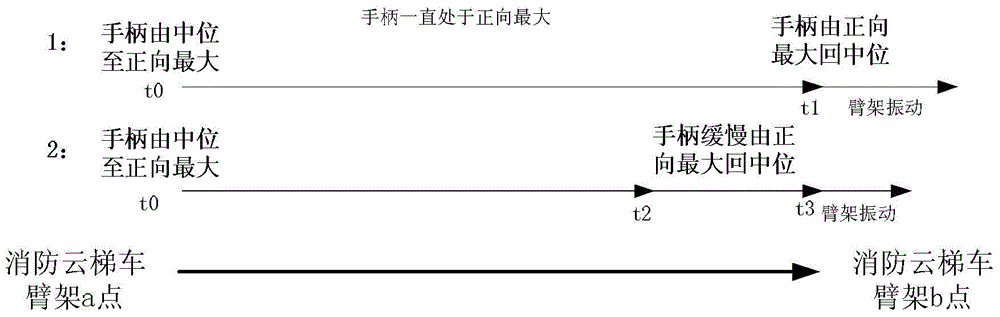

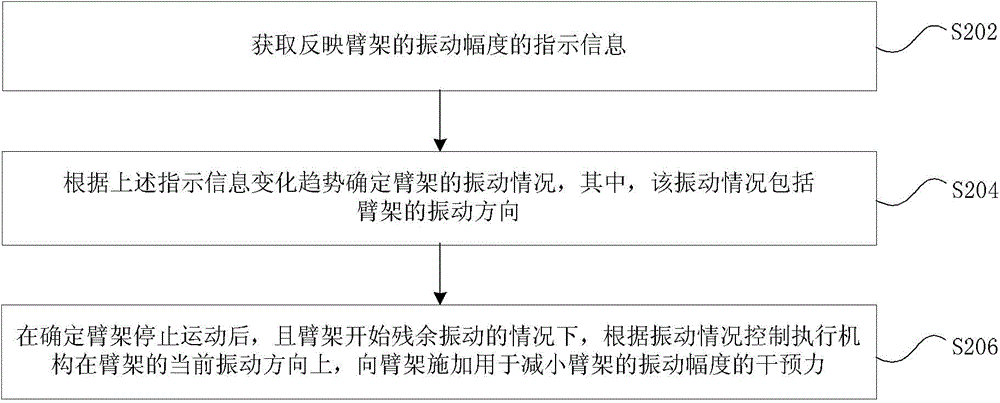

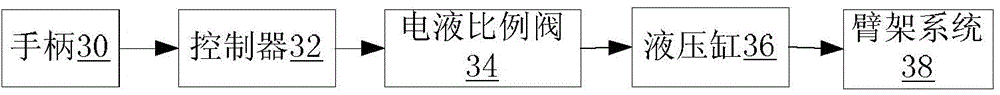

Method and device for suppressing residual oscillation of cantilever crane

ActiveCN103629293AReduce vibration amplitudeFast steady stateVibration suppression adjustmentsCantileverComputer science

The invention provides a method and a device for suppressing residual oscillation of a cantilever crane, which are applied to an engineering machine. The engineering machine comprises the cantilever crane and an actuating mechanism for controlling the movement of the cantilever crane. The method comprises the following steps of acquiring indication information reflecting the oscillation amplitude of the cantilever crane; determining the oscillation situation of the cantilever crane according to the variation trend of the indication information, wherein the oscillation situation comprises the oscillation direction of the cantilever crane; controlling the actuating mechanism to apply the interference force for reducing the oscillating amplitude of the cantilever crane onto the cantilever crane in the current oscillation direction of the cantilever crane according to the oscillation situation under the situation that the cantilever crane stops movement and the residual oscillation of the cantilever crane is started. By utilizing the technical scheme, the technical problems in the prior art that the time for stabilizing the cantilever crane is long, the residual oscillation amplitude is large and the like can be solved, so that the cantilever crane can be rapidly stabilized after the variable-amplitude movement is stopped, and the working efficiency is improved.

Owner:ZOOMLION HEAVY IND CO LTD

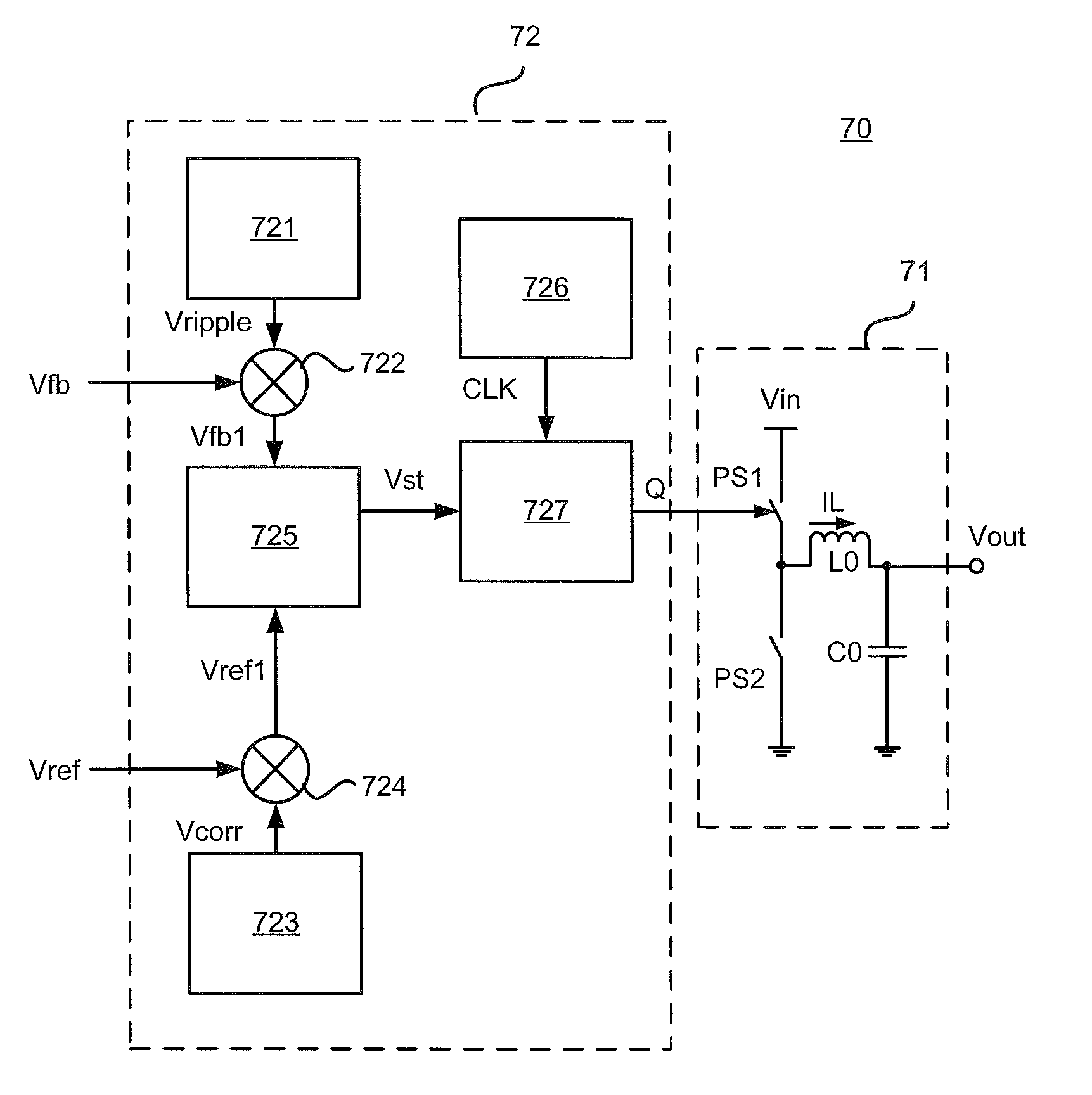

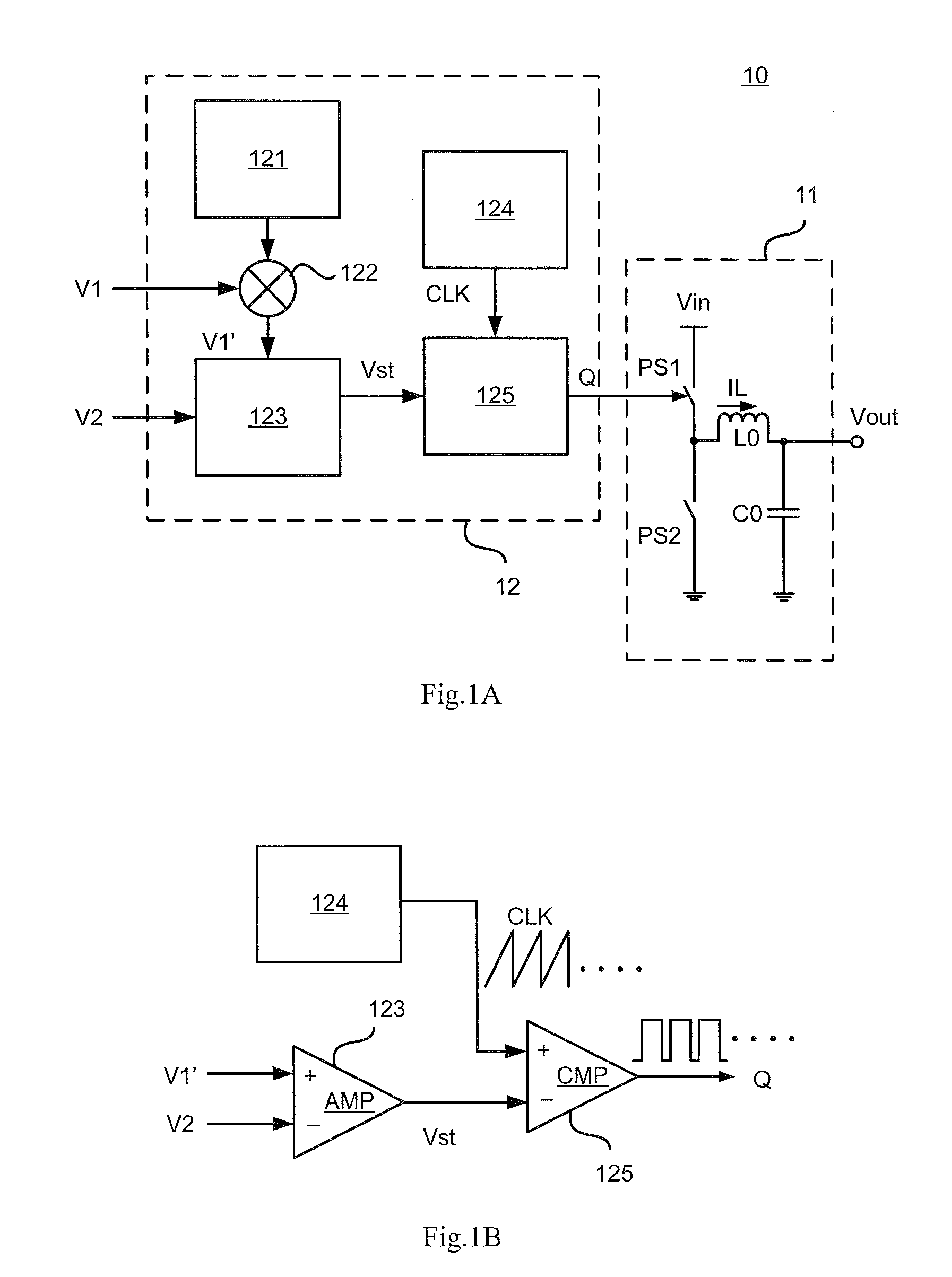

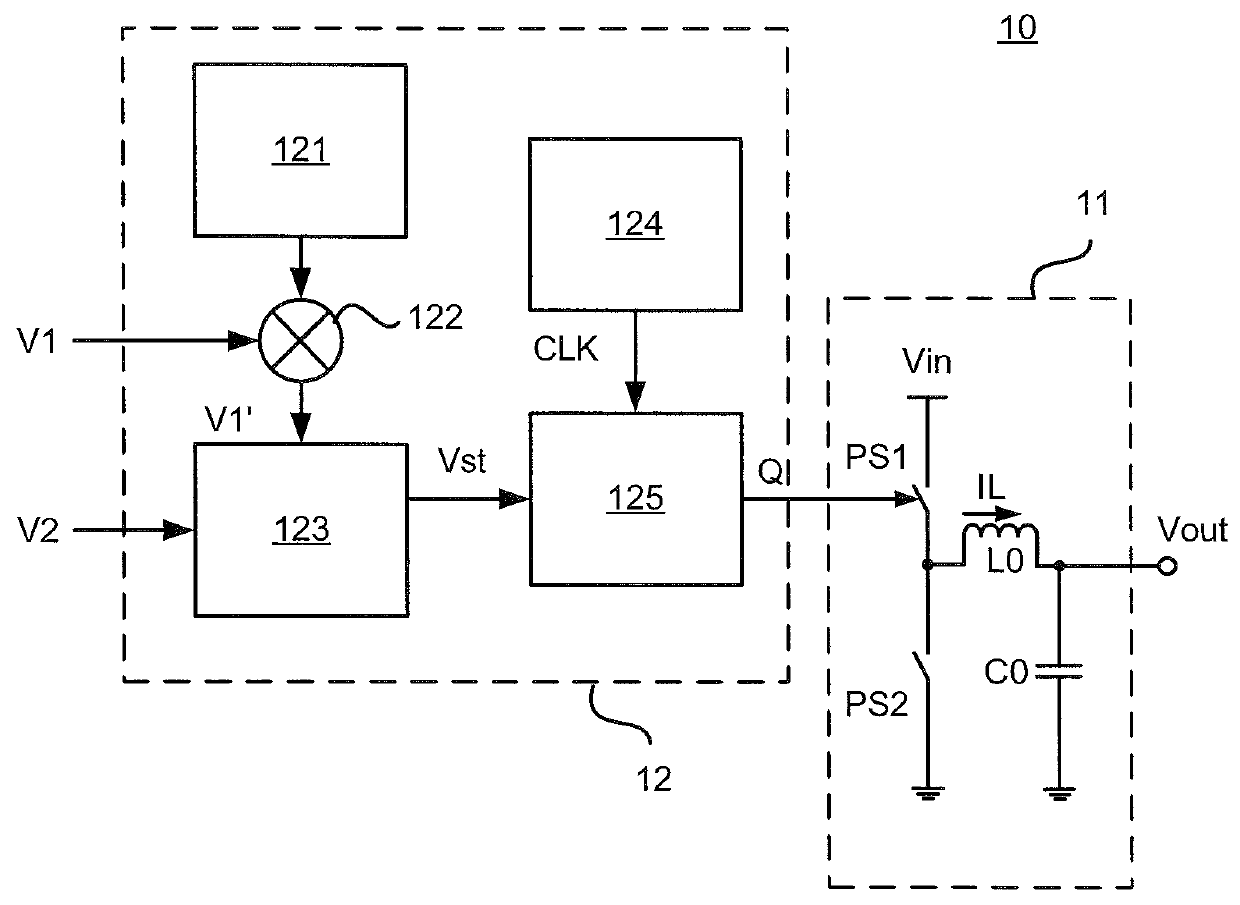

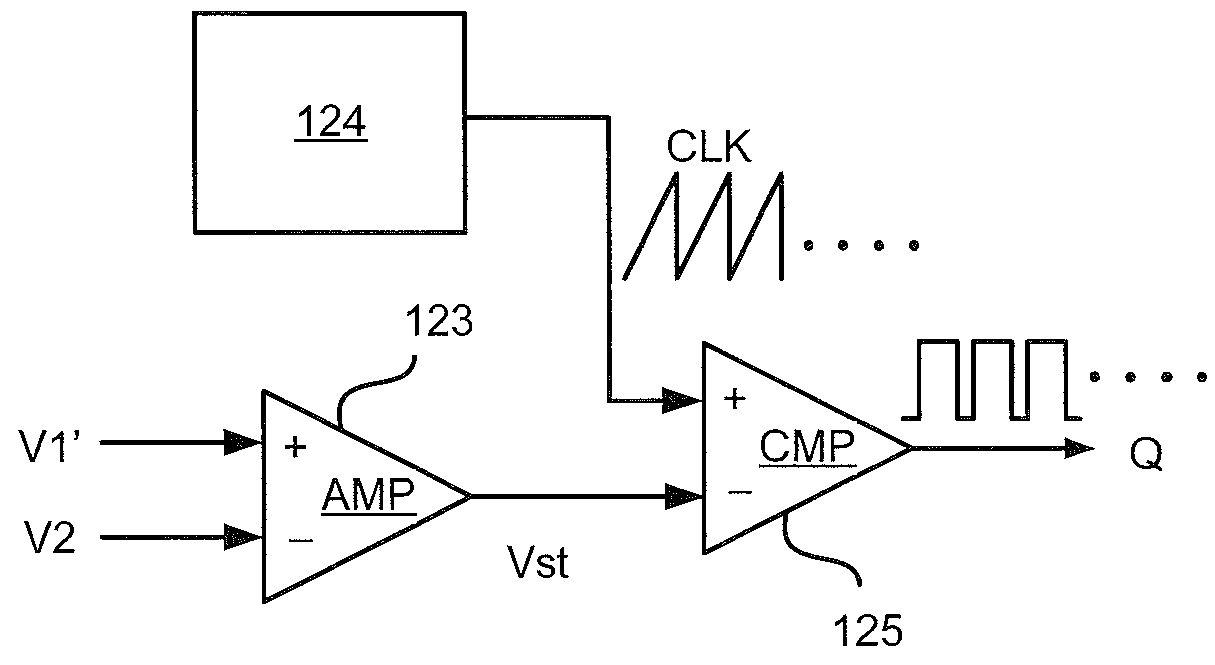

Switching regulator and control circuit and control method therefor

ActiveUS20150188430A1Fast steady stateAvoid output voltageEfficient power electronics conversionDc-dc conversionState parameterControl theory

Disclosed are a switching regulator and a control circuit and a control method therefor. In one embodiment, the control circuit generates a supplementary signal varying with a state parameter of the power stage in a first mode and keeps the supplementary signal substantially unchanged in a second mode with respect to the value thereof at the moment of switching from the first mode to the second mode so that the supplementary signal at the moment of mode switching is maintained substantially constant, therefore, a steady state can be achieved quickly, and ripples in the output voltage are restrained.

Owner:SILERGY SEMICON TECH (HANGZHOU) CO LTD

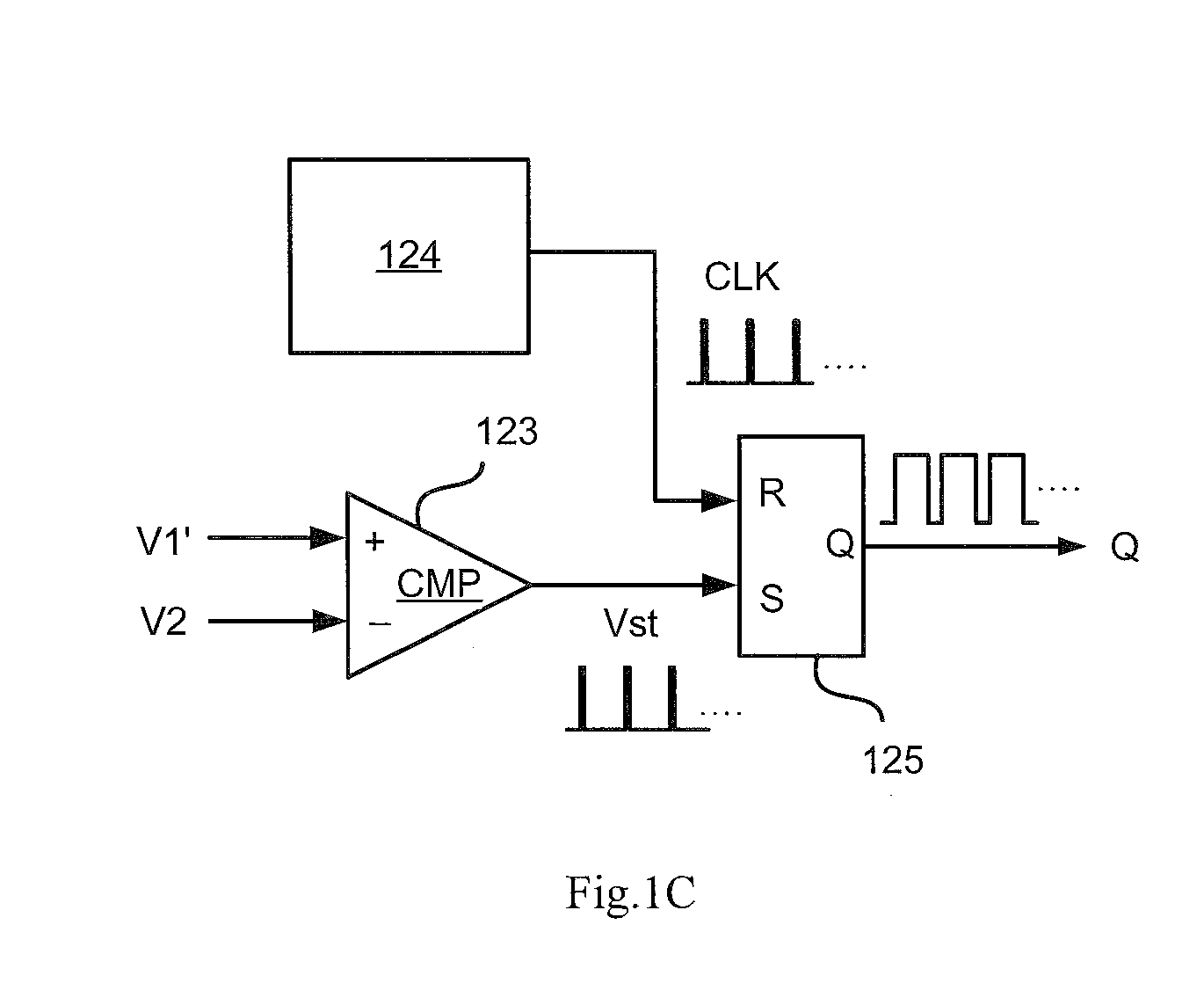

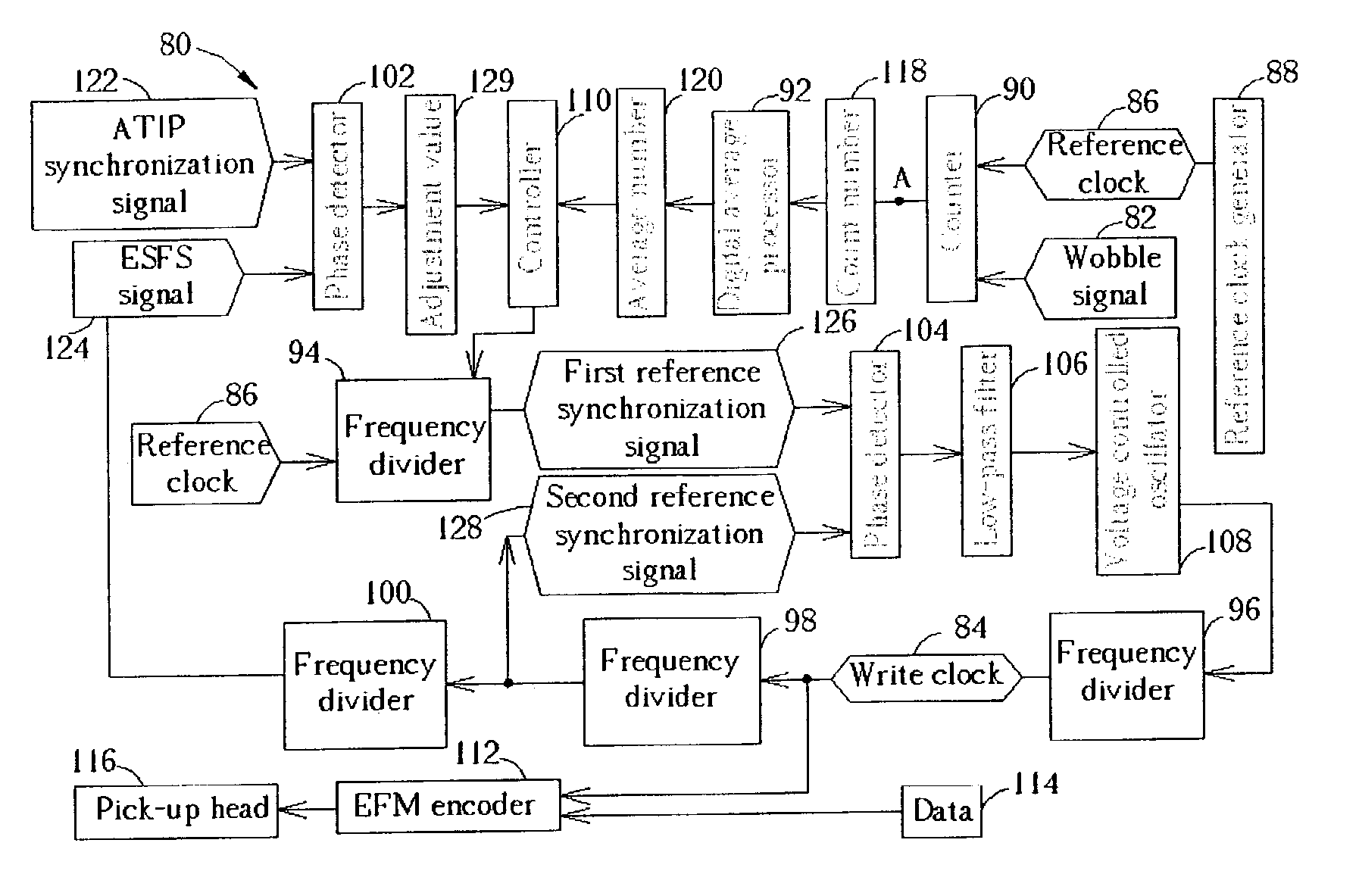

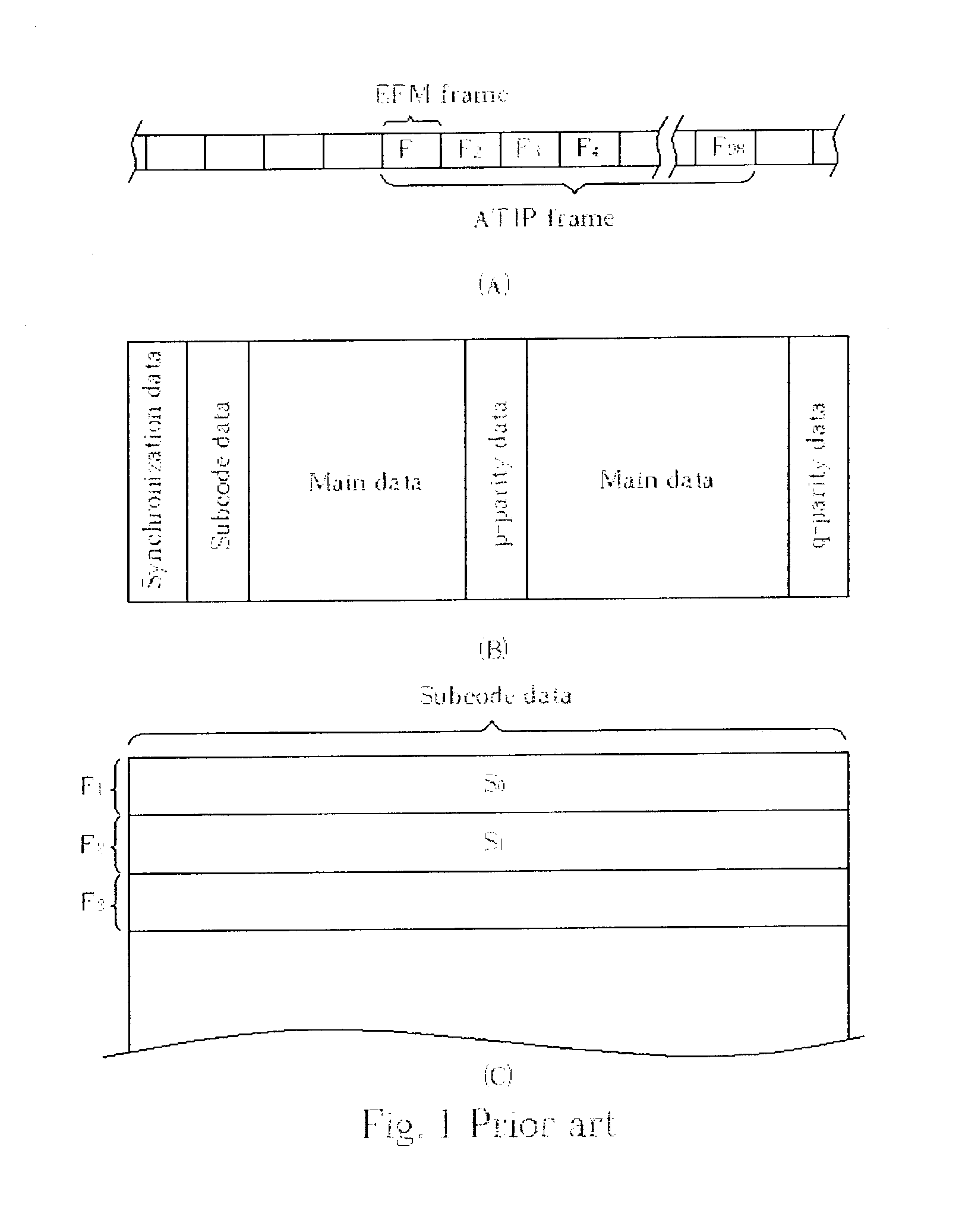

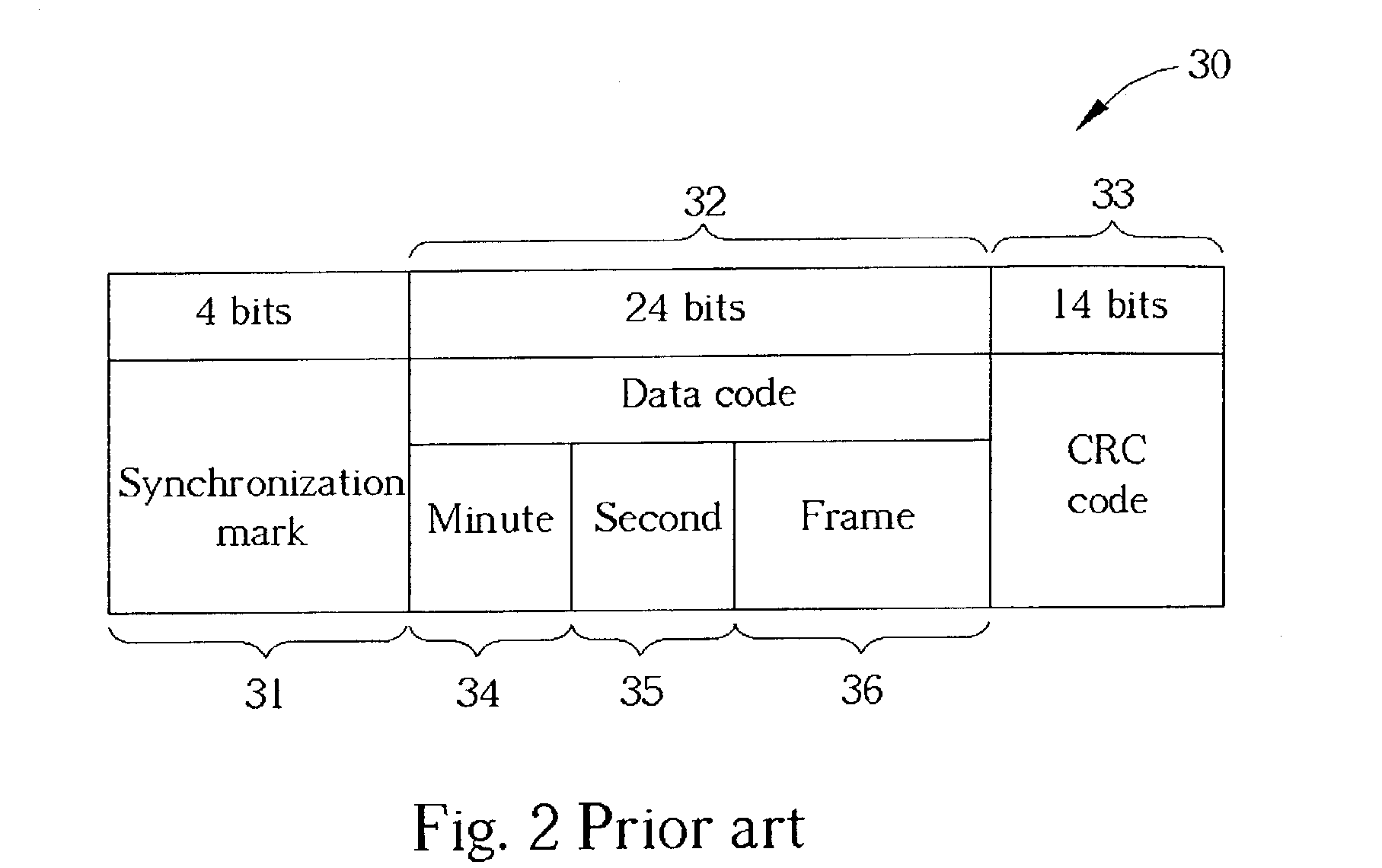

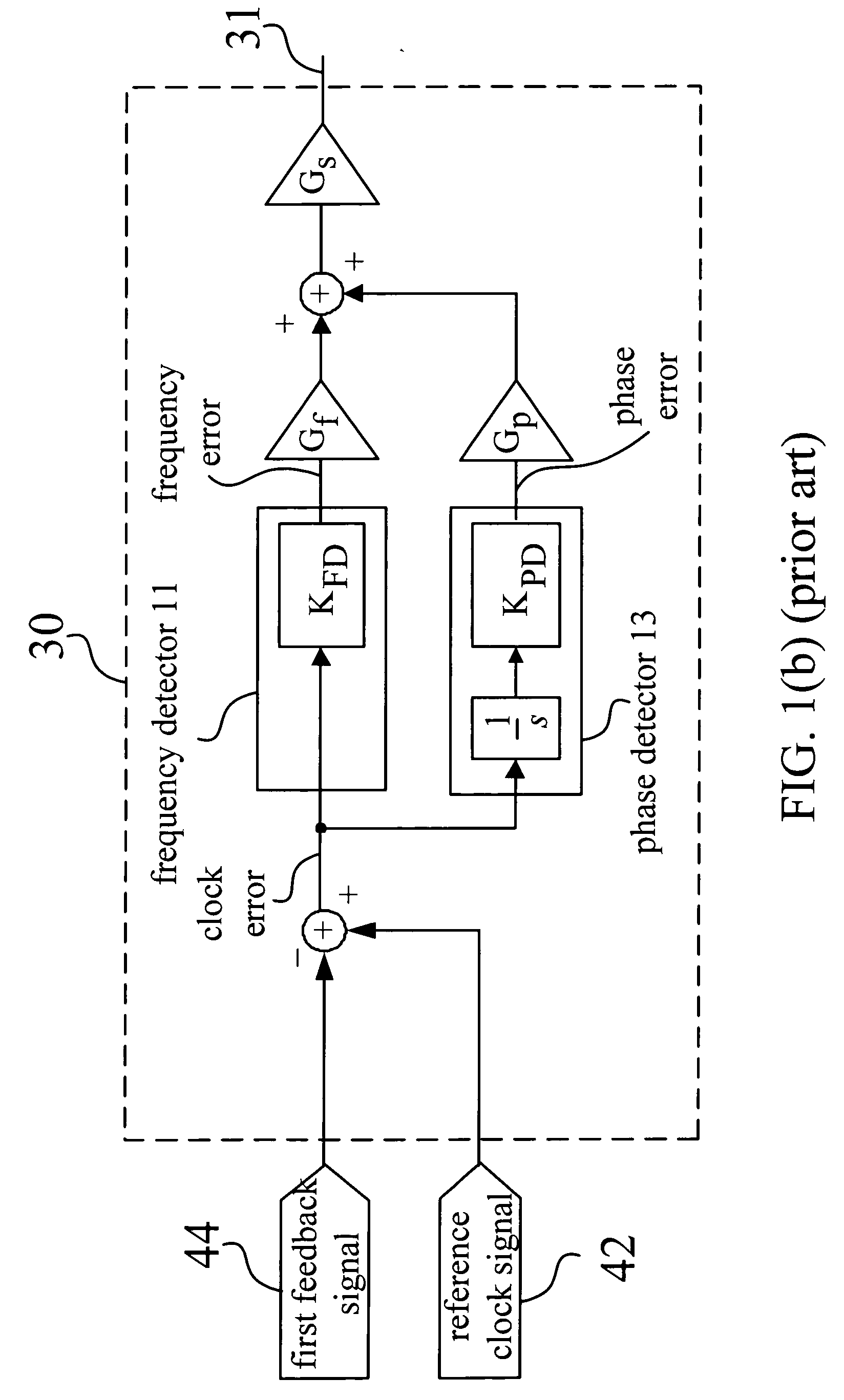

Method and device for generating a write clock of a constant angular velocity optical disk device

InactiveUS7016277B2Shorten lock timeProcessing time requiredCombination recordingPulse automatic controlComputer hardwarePhase detector

A method for generating a write clock of a constant angular velocity compact storage device and the device thereof. The compact storage device has a counter for generating a count number by a reference clock counting a wobble signal, and a phase detector for generating an adjustment value by comparing a phase shift between an ATIP synchronization signal and an encoded subcode frame synchronization signal. According to the count number and the adjustment value, a rectification value is found, and the rectification value and the reference clock is used for generating a reference write clock to modify the encoded subcode frame synchronization signal. If the phase shift between an ATIP synchronization signal and an encoded subcode frame synchronization signal is smaller than a predetermined value, the reference write clock is the write clock used by the compact storage device.

Owner:TIAN HLDG

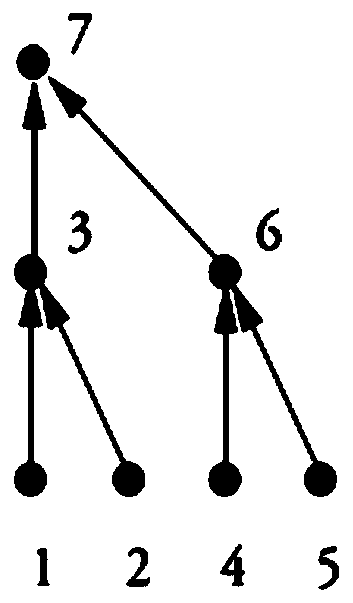

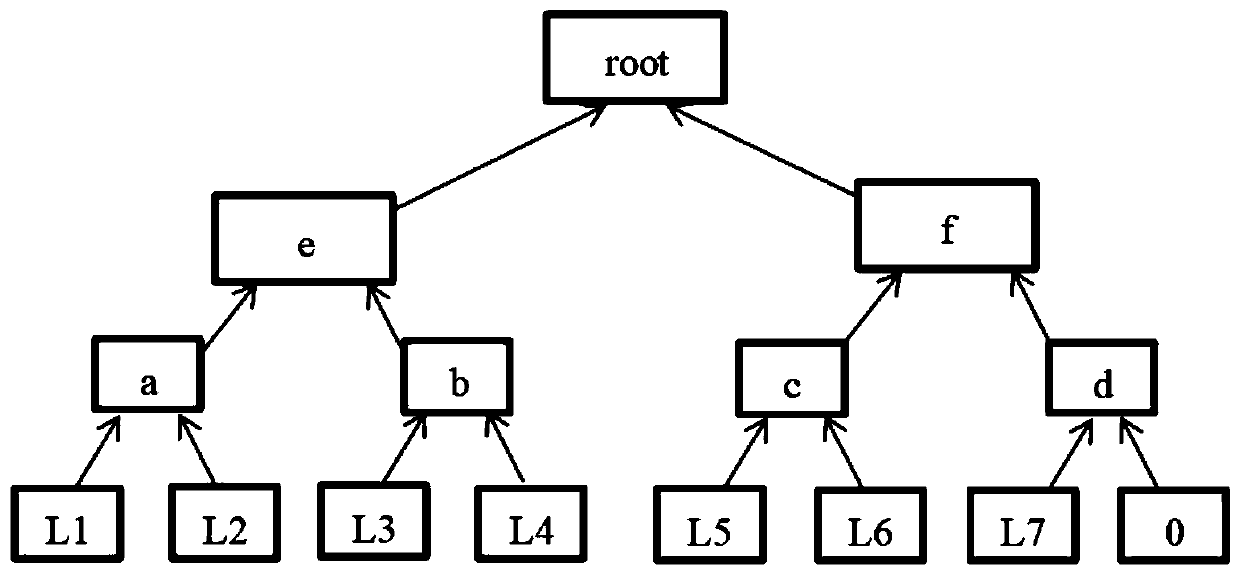

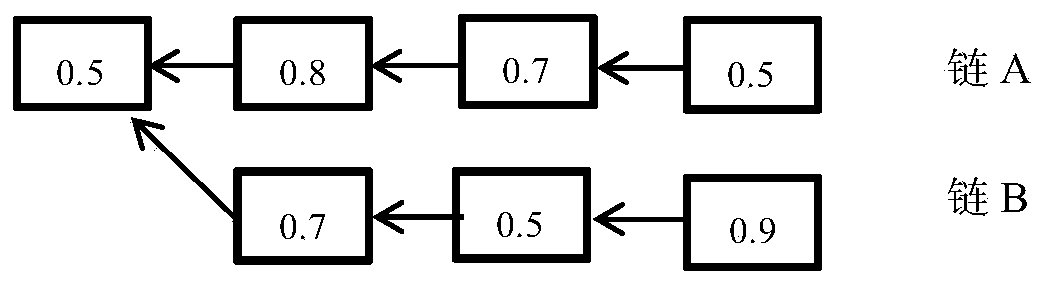

Blockchain method and system based on storage proof

ActiveCN111078686ASolve the real problemReduce consumptionFinanceDatabase distribution/replicationFinancial transactionDataspaces

The invention provides a blockchain method and system based on storage proof. The method comprises the following steps: a storage data generation step: each new miner newly joining a network generatesdata needing to be stored by using the new miner; and a spatial declaration transaction broadcasting step: the new miner newly joining the network generates a Merkel commitment according to the stored data, the new miner regenerates and broadcasts a spatial declaration transaction, and the size of a hard disk space put into the new miner and the Merkel commitment for the stored data are declaredto the whole network. The invention provides a blockchain scheme based on storage proof. The problems existing in conventional block chain schemes based on PoW, PoS and the like are effectively solved, through ingenious design of a reasonable block scoring function, the probability that a miner successfully excavates a legal block is in direct proportion to the space size of a hard disk into whichthe miner inputs, and therefore competition fairness of the miner is guaranteed.

Owner:SHANGHAI JIAO TONG UNIV

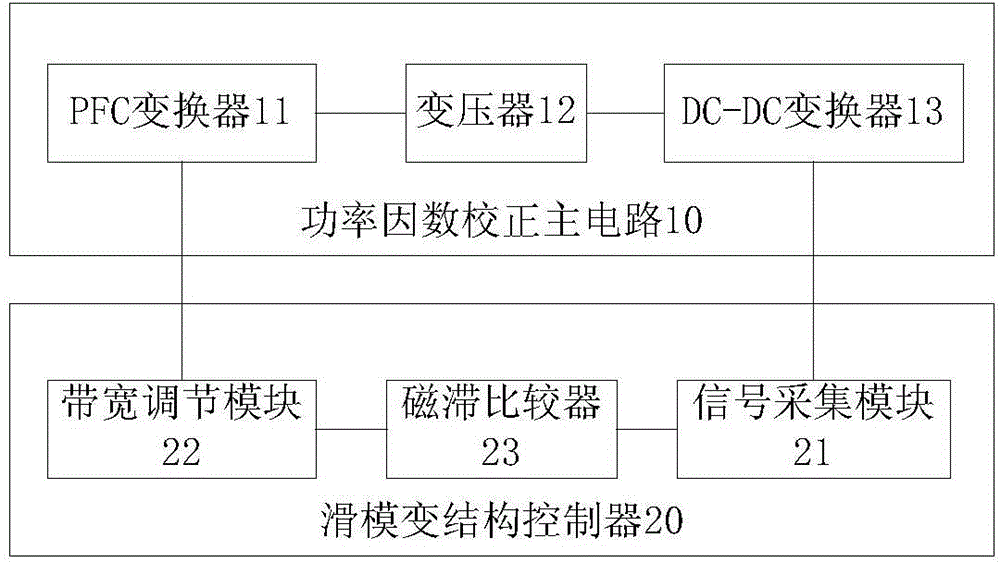

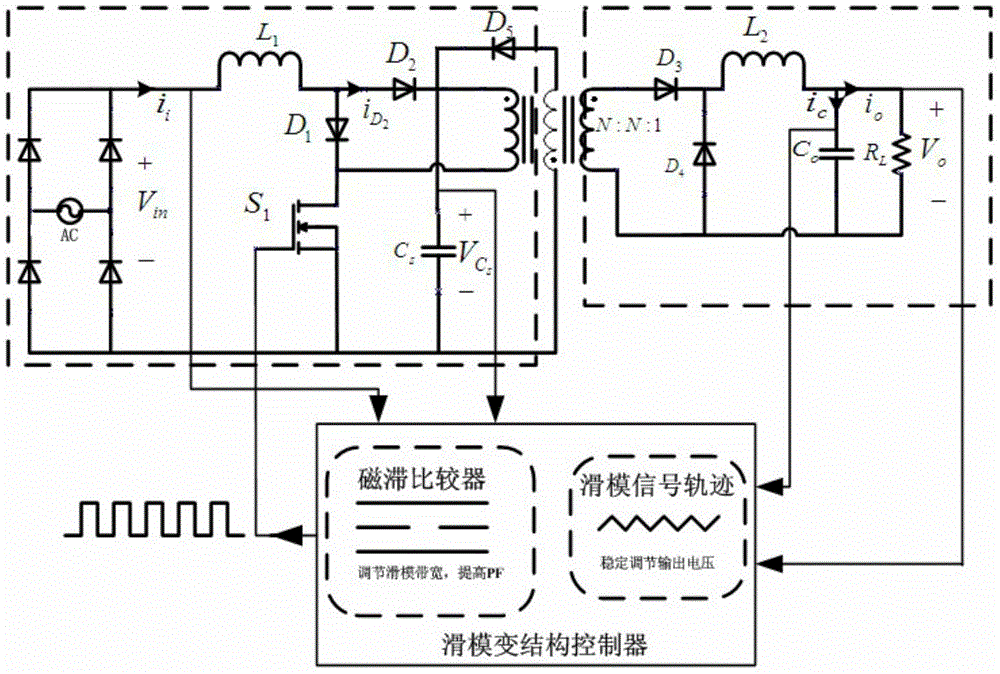

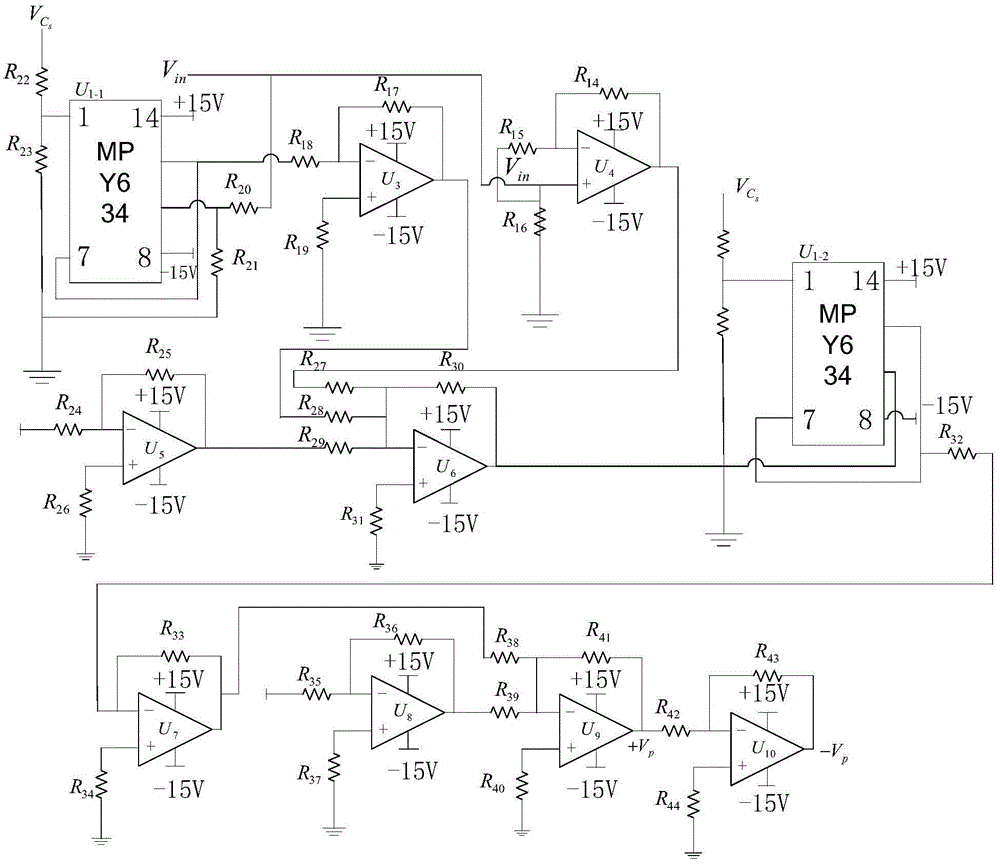

Device and method for correcting power factor

InactiveCN103560663AReduce output voltageIncrease the output voltageEfficient power electronics conversionEnergy industryControl signalCapacitor voltage

The invention discloses a device and method for correcting a power factor. The device comprises a main power factor correcting circuit and a sliding mode variable structure controller. The sliding mode variable structure controller comprises a signal collecting module, a bandwidth adjusting module and a hysteresis comparator. The bandwidth adjusting module is used for receiving input voltage and buffering capacitor voltage of the main power factor correcting circuit and outputting a bandwidth, and the output bandwidth is changed along with the changes of the input voltage to change the frequency of a switch tube of the main power factor correcting circuit. The signal collecting module is used for collecting the feedback voltage of an output signal of the main power factor correcting circuit. The hysteresis comparator is used for producing a sliding mode signal track according to the comparison result between the feedback voltage collected by the signal collecting module and the given reference voltage, the sliding mode signal track is compared with the bandwidth, a periodical control signal is produced, and the duty ratio of the main power factor correcting circuit is adjusted through the control signal to change the output voltage of the main power factor correcting circuit.

Owner:WUHAN UNIV OF TECH

Switching regulator and control circuit and control method therefor

ActiveUS9343965B2Fast steady stateAvoid output voltageEfficient power electronics conversionDc-dc conversionStable stateState parameter

Disclosed are a switching regulator and a control circuit and a control method therefor. In one embodiment, the control circuit generates a supplementary signal varying with a state parameter of the power stage in a first mode and keeps the supplementary signal substantially unchanged in a second mode with respect to the value thereof at the moment of switching from the first mode to the second mode so that the supplementary signal at the moment of mode switching is maintained substantially constant, therefore, a steady state can be achieved quickly, and ripples in the output voltage are restrained.

Owner:SILERGY SEMICON TECH (HANGZHOU) CO LTD

Method of using SMA wire to drive active part to move

ActiveCN109960001AImprove work efficiencyFast steady stateTelevision system detailsColor television detailsEngineering

Owner:NINGBO SUNNY OPOTECH CO LTD

Communication timing control method and apparatus, node, and communication system

InactiveUS7602764B2Avoid Signal ConflictsFast steady stateSynchronisation arrangementTime-division multiplexCommunications systemCommunication unit

A communication timing control apparatus for use in the nodes of a communication system includes a signal communication unit that transmits a state variable signal to neighboring nodes and receives state variable signals from those nodes. An external control signal, such as a beacon signal transmitted by a control node, is also received. The state variable signals indicate internal operating states or timings of the nodes; the control signal indicates a basic transition rate. A timing decision unit causes internal state or timing transitions to occur at timings responsive to the basic transition rate and the received state variable signals, adjusting the transition timings so as to avoid signal collisions and to adapt to changing system conditions, Use of the control signal enables a steady timing state to be reached quickly.

Owner:OKI ELECTRIC IND CO LTD

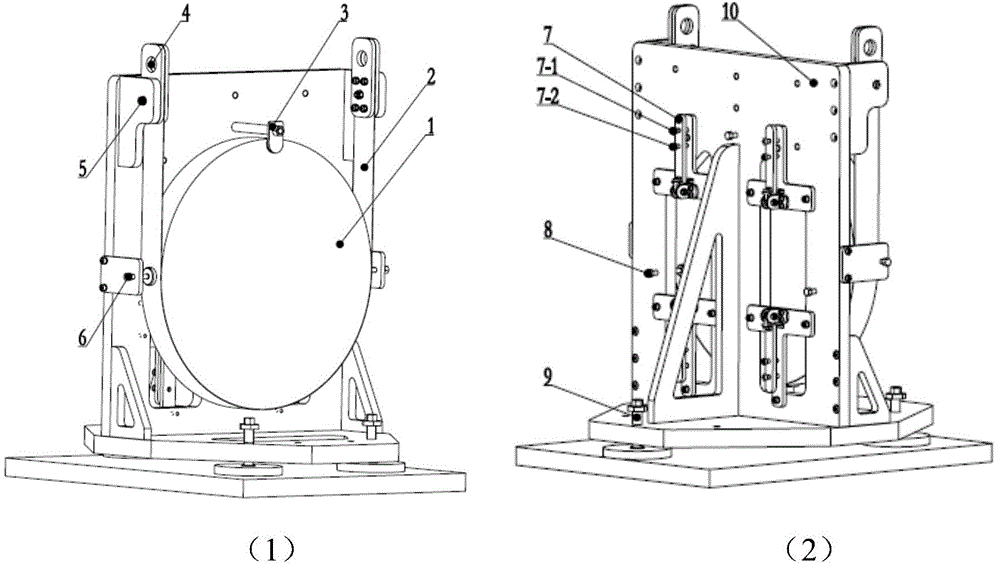

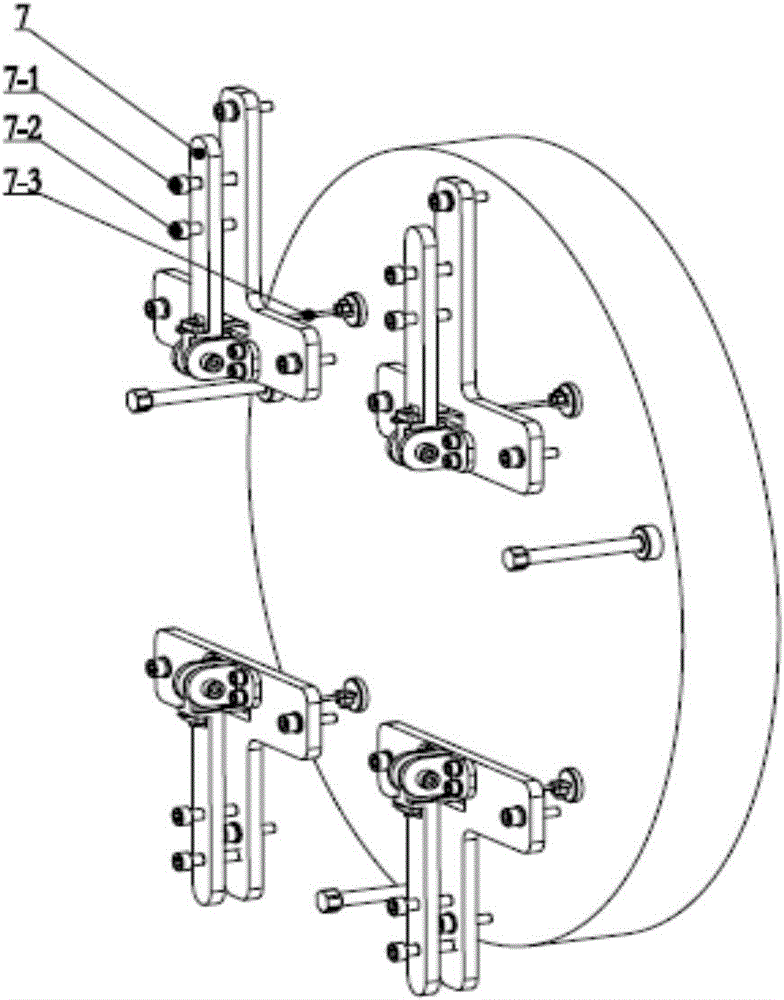

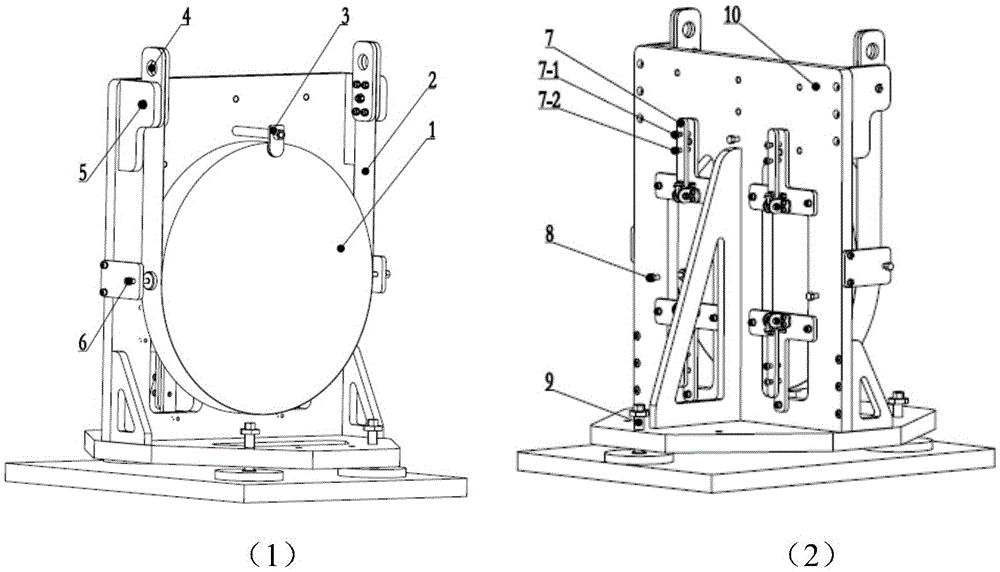

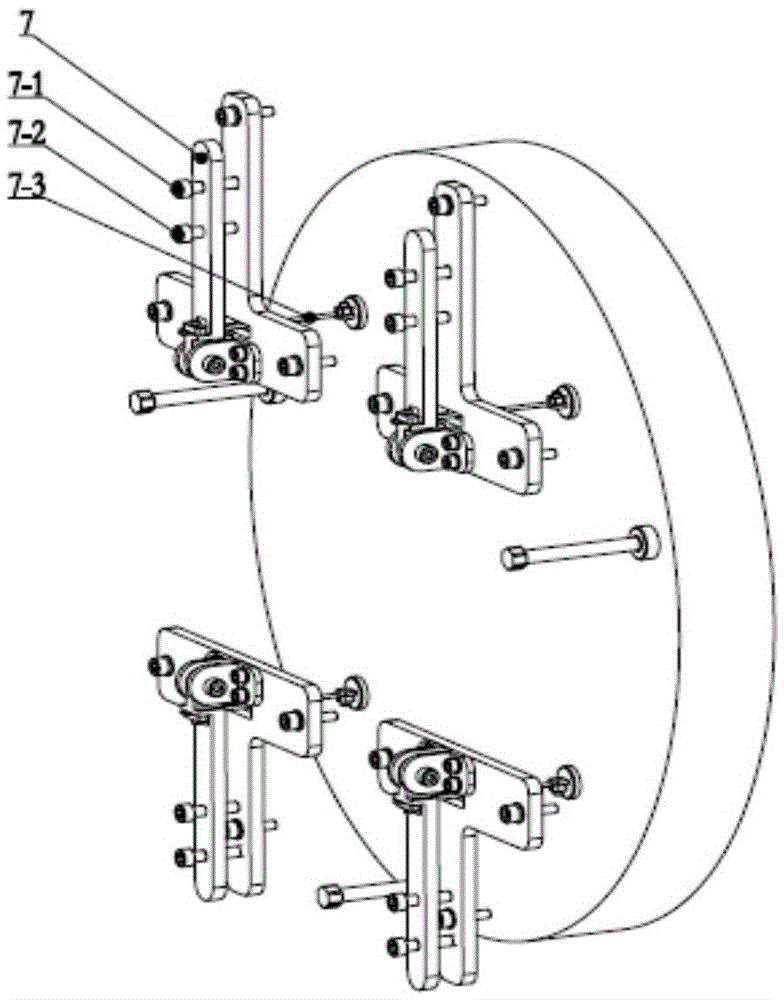

Shock absorption and adjustment mechanism of plane mirror

The invention discloses a shock absorption and adjustment mechanism of a plane mirror. The plane mirror is suspended on a main structure through a thin steel strip and a half-thread bolt, and the functions of shock absorption and high-precision adjustment for the plane mirror are achieved through a lateral threaded adjusting rod, a back adjusting mechanism, a back threaded adjusting rod and a bottom threaded adjusting rod of the plane mirror. The shock absorption and adjustment mechanism has the advantage that under the condition that the plane mirror deforms slightly, the plane mirror can be stable fast through the high-precision adjusting mechanism.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

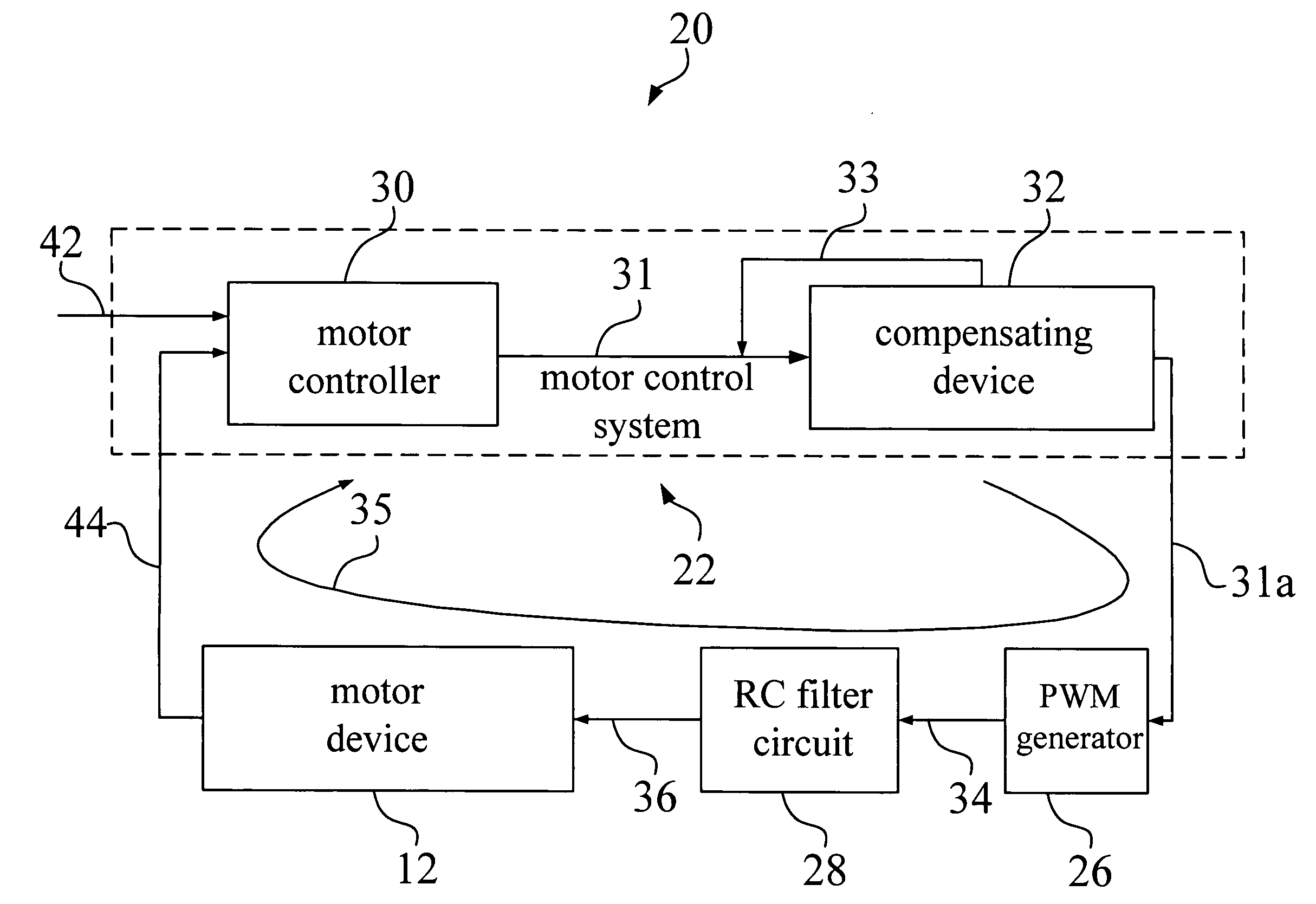

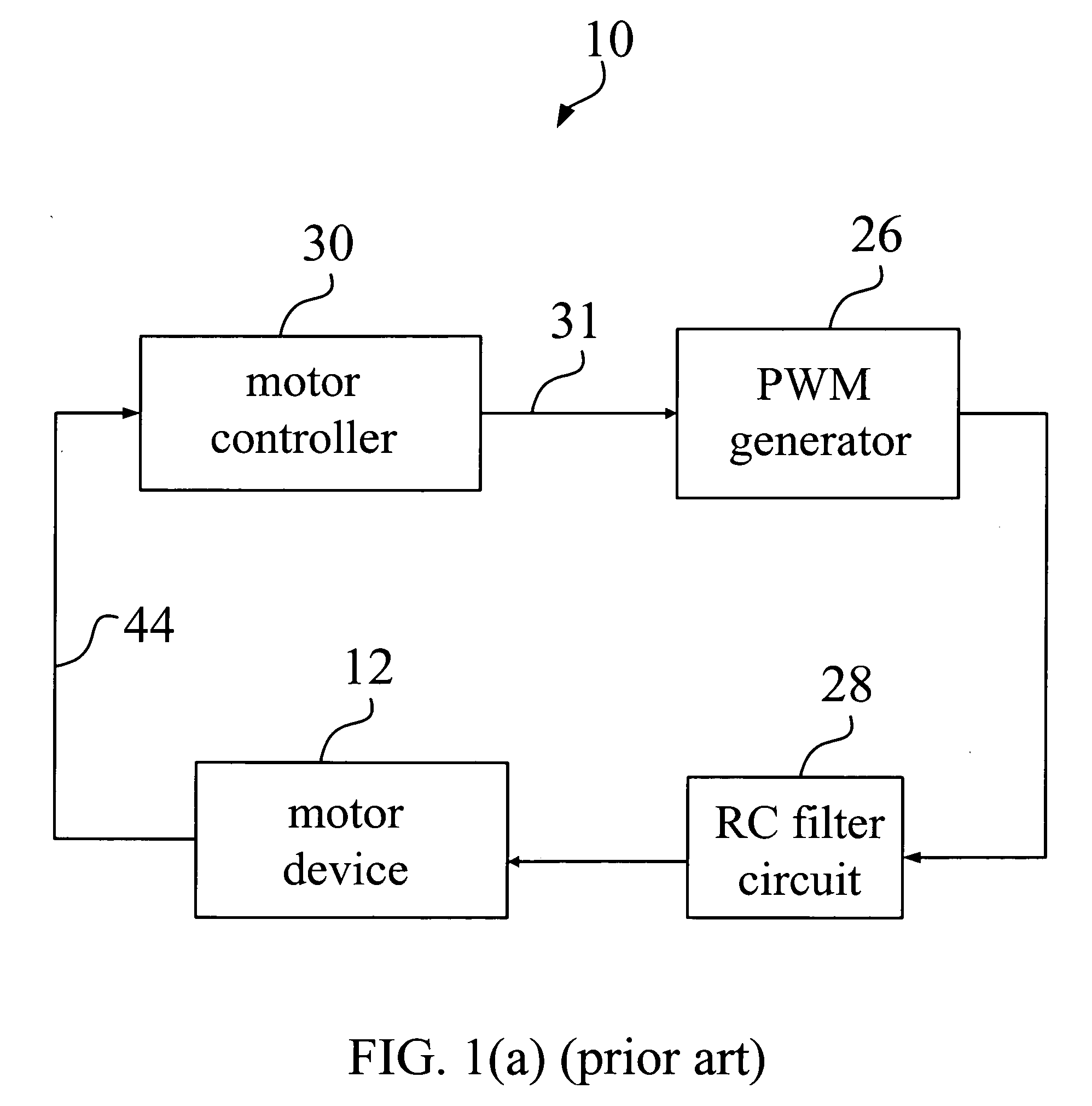

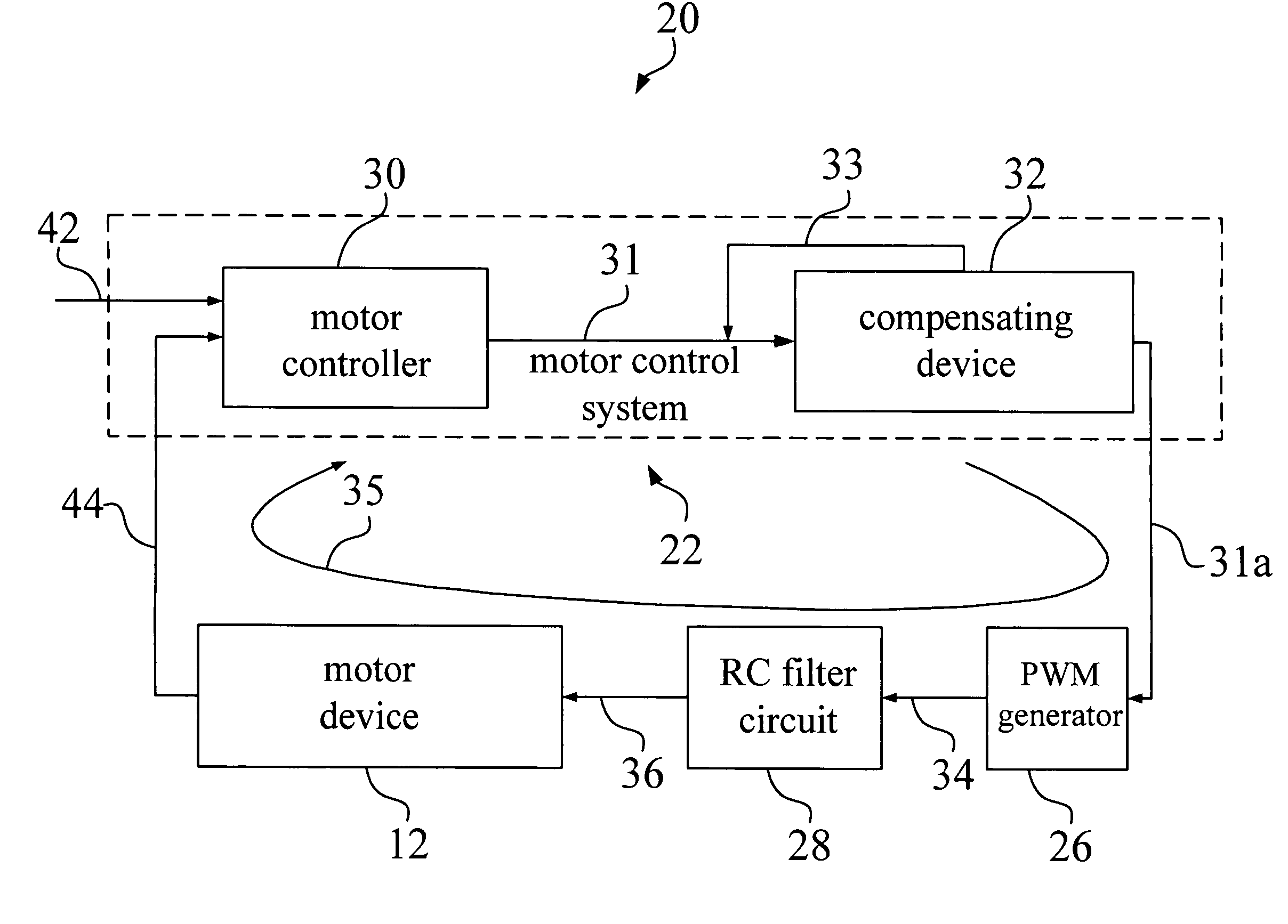

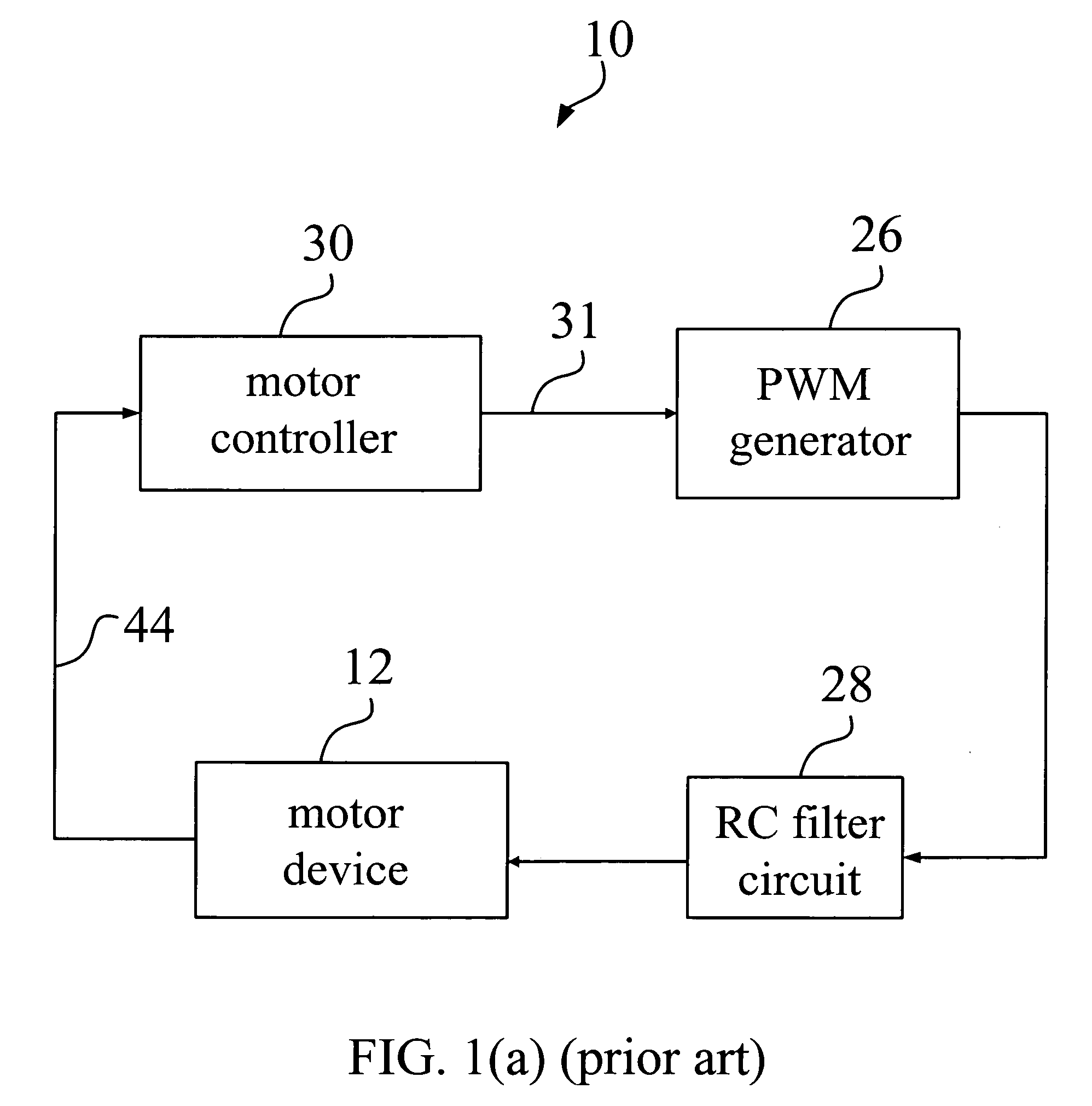

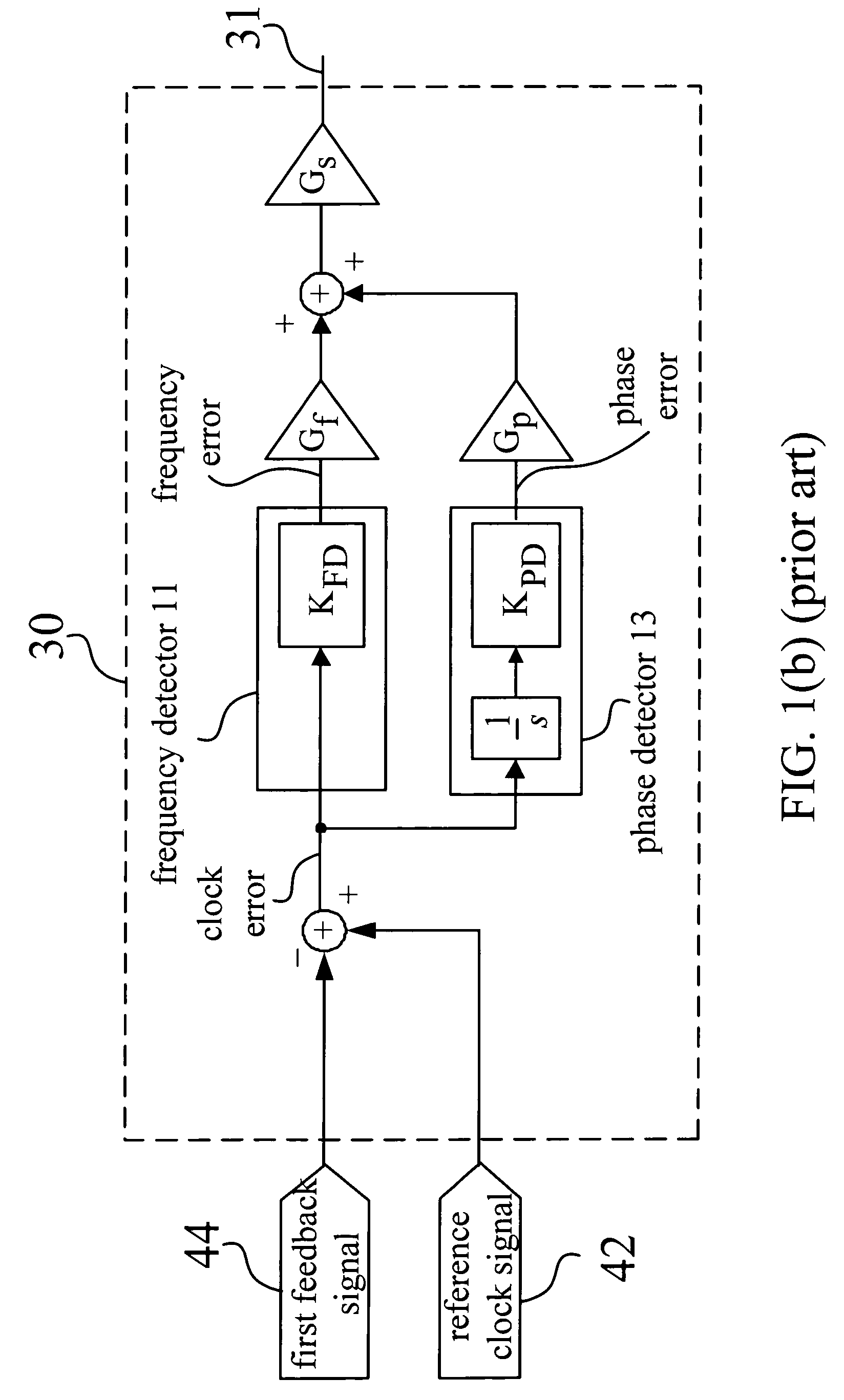

Motor control system and method of the same

ActiveUS20050206338A1Reduce errorsShort transition timeElectric motor controlTemperatue controlControl systemMotor controller

The present invention provides a motor control system and method thereof. The motor control system comprises a motor controller and a compensation device. The motor controller is used for generating a motor control output according to a reference signal and a first signal. The compensation device is used for generating a compensated motor control output according to the motor control output and a second signal. Moreover, the compensation device utilizes the compensated motor control output to reduce the steady-state phase error between the first signal and the reference signal.

Owner:MEDIATEK INC

Motor control system and method of the same

ActiveUS7138782B2Reduce errorsShort transition timeElectric motor controlTemperatue controlControl systemMotor controller

The present invention provides a motor control system and method thereof. The motor control system comprises a motor controller and a compensation device. The motor controller is used for generating a motor control output according to a reference signal and a first signal. The compensation device is used for generating a compensated motor control output according to the motor control output and a second signal. Moreover, the compensation device utilizes the compensated motor control output to reduce the steady-state phase error between the first signal and the reference signal.

Owner:MEDIATEK INC

Method and control unit for adapting an upper headlight beam boundary of a light cone

ActiveUS9260051B2Save computing powerShorten the timeVehicle headlampsDigital data processing detailsControl signalLight beam

A method for adapting an upper headlight beam boundary of a light cone of at least one headlight of a vehicle. The method includes detecting a time curve of a pitch rate of the vehicle or a value that is dependent on the pitch rate and / or of a roll rate of the vehicle or a value that is dependent on the roll rate. The method also includes ascertaining an envelope curve and / or an amplitude of the time curve and / or an average value of the time curve. The method also includes providing a control signal for adapting the upper headlight beam boundary of the headlight beam.

Owner:ROBERT BOSCH GMBH

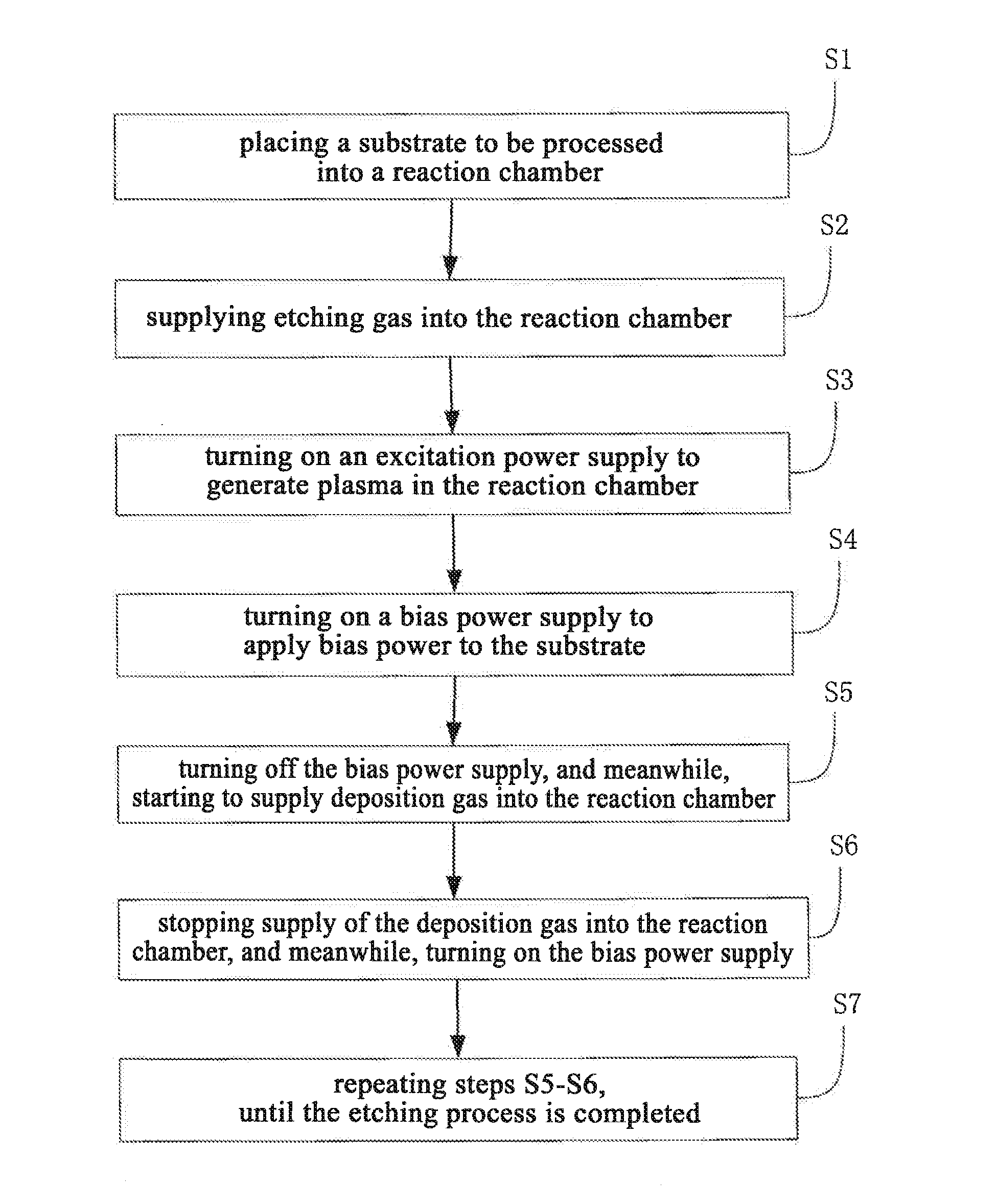

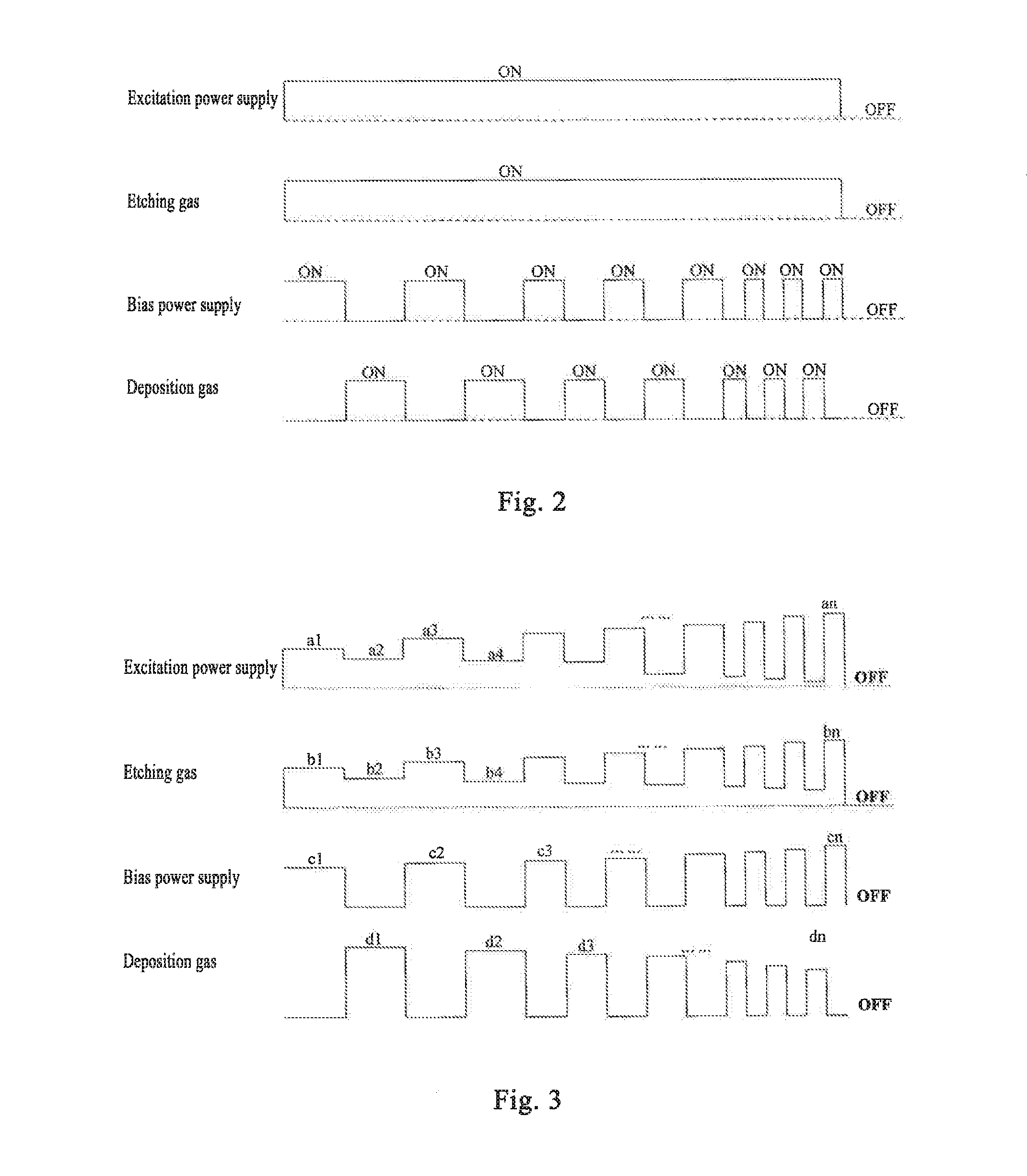

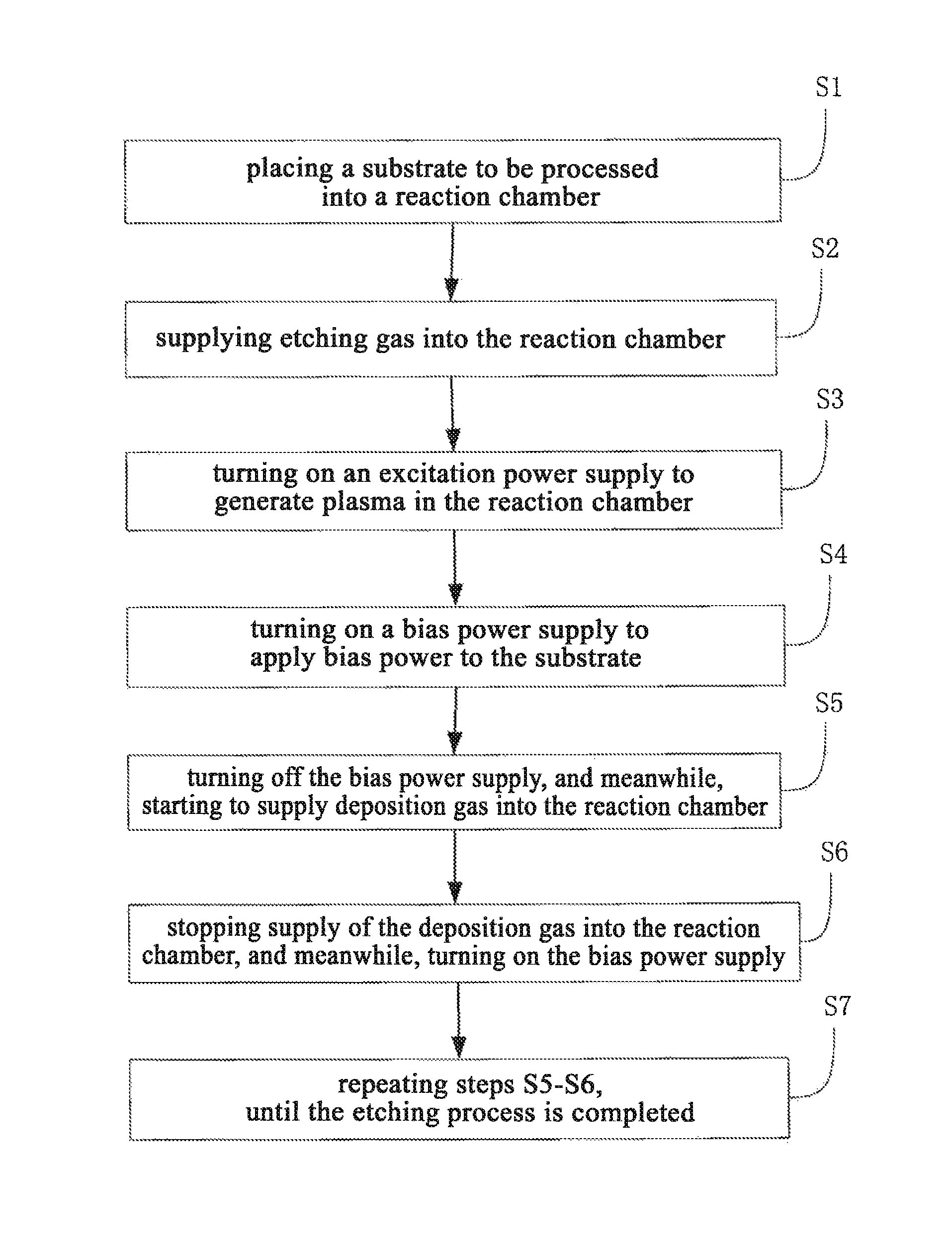

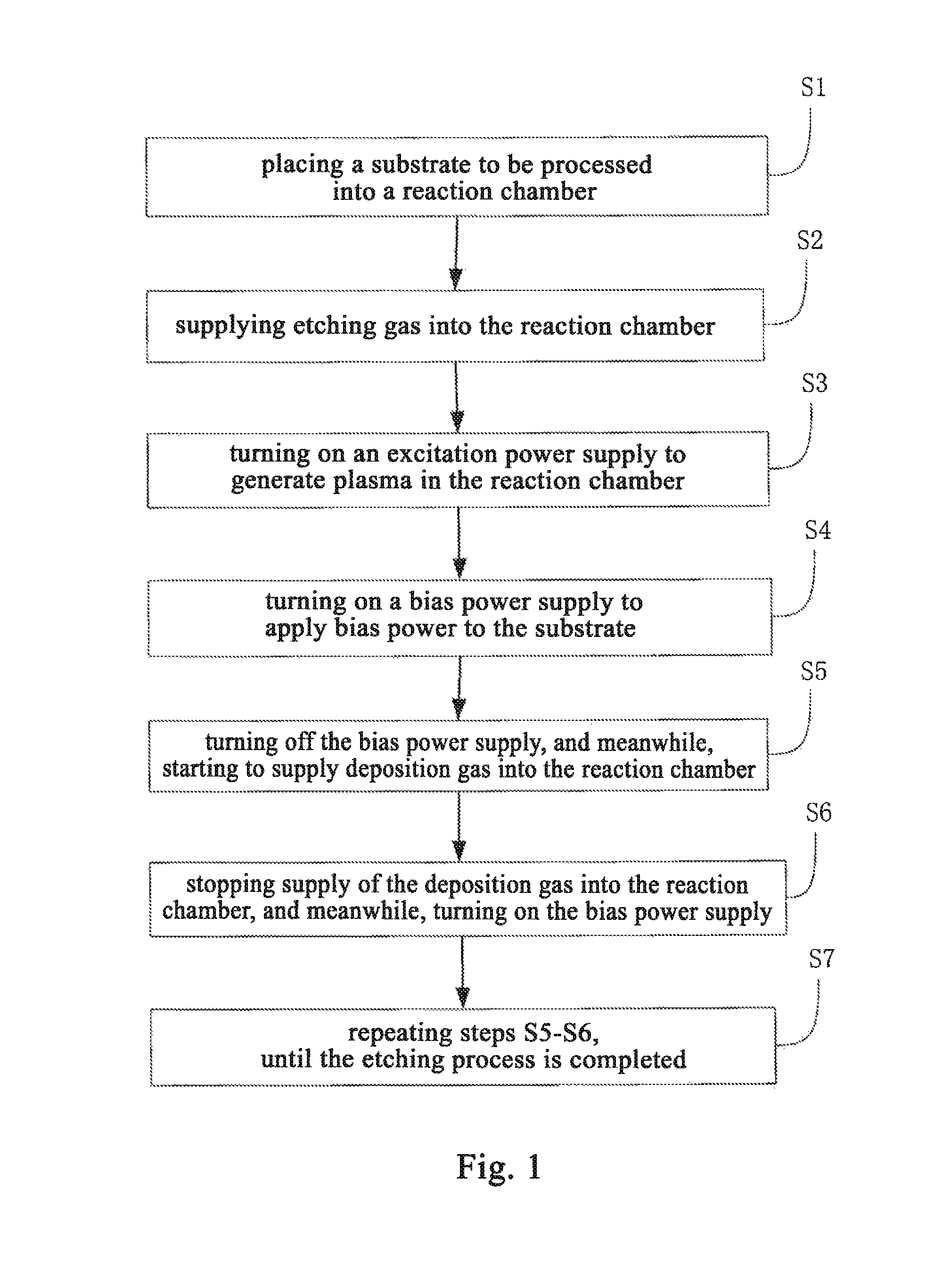

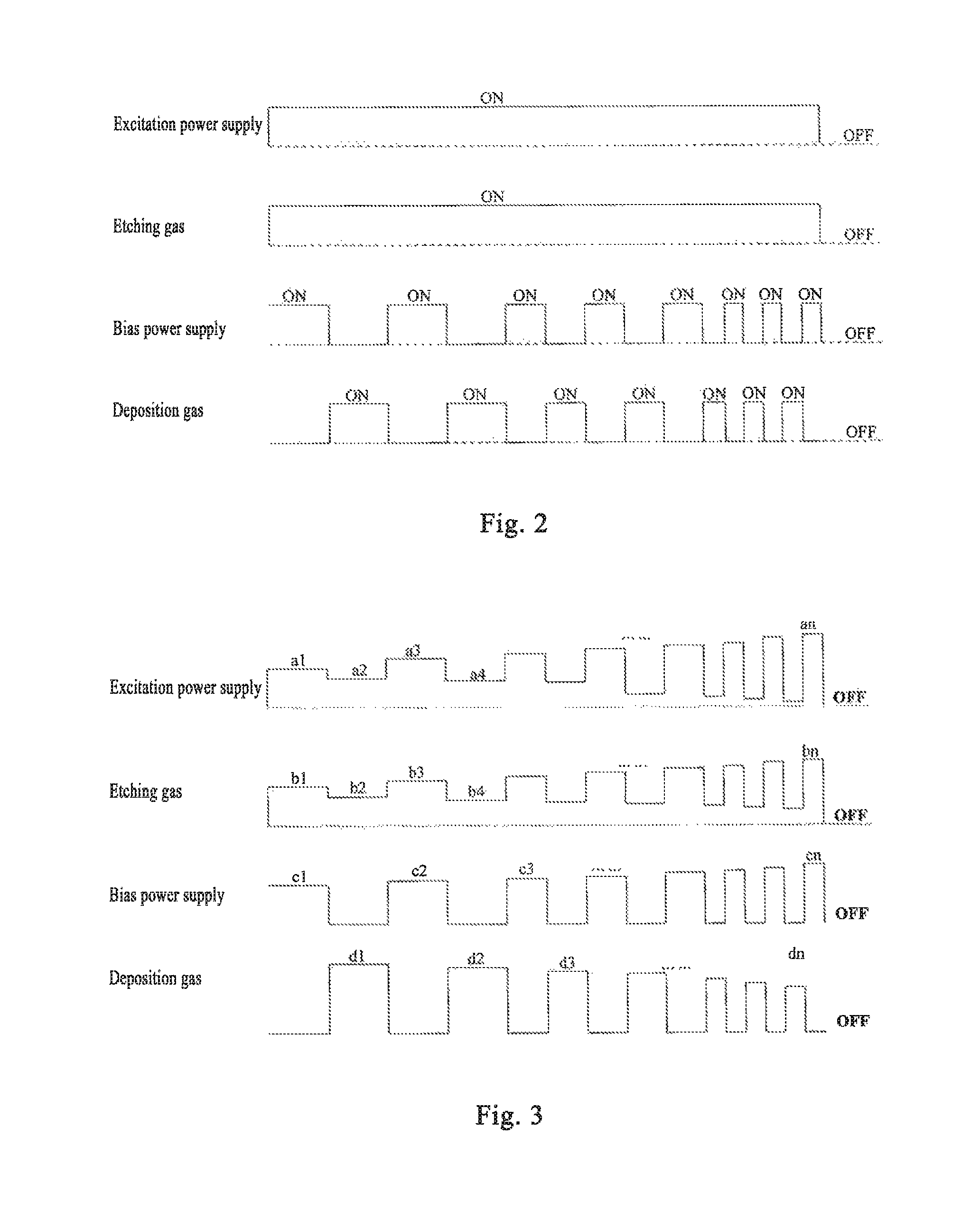

Substrate etching method and substrate processing device

ActiveUS20140363975A1Improve processing qualityEasy to processDecorative surface effectsSemiconductor/solid-state device manufacturingEtchingEngineering

A substrate etching method and a substrate processing device, the substrate etching method includes: S1: placing a substrate to be processed into a reaction chamber; S2: supplying etching gas into the reaction chamber; S3: turning on an excitation power supply to generate plasma in the reaction chamber; S4: turning on a bias power supply to apply bias power to the substrate; S5: turning off the bias power supply, and meanwhile, starting to supply deposition gas into the reaction chamber; S6: stopping supply of the deposition gas into the reaction chamber, and meanwhile, turning on the bias power supply; S7: repeating steps S5-S6, until the etching process is completed. In the whole etching process, the etching operation is always performed, and the deposition operation is performed sometimes. Therefore, during the deposition operation, the plasma in the reaction chamber can etch away at least a part of deposited polymers formed by the deposition operation on a sidewall of an etched section, so that the sidewall of the etched section of the substrate is smooth.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Substrate etching method and substrate processing device

ActiveUS9187319B2Improve processing qualityFast steady stateDecorative surface effectsSemiconductor/solid-state device manufacturingEtchingEngineering

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

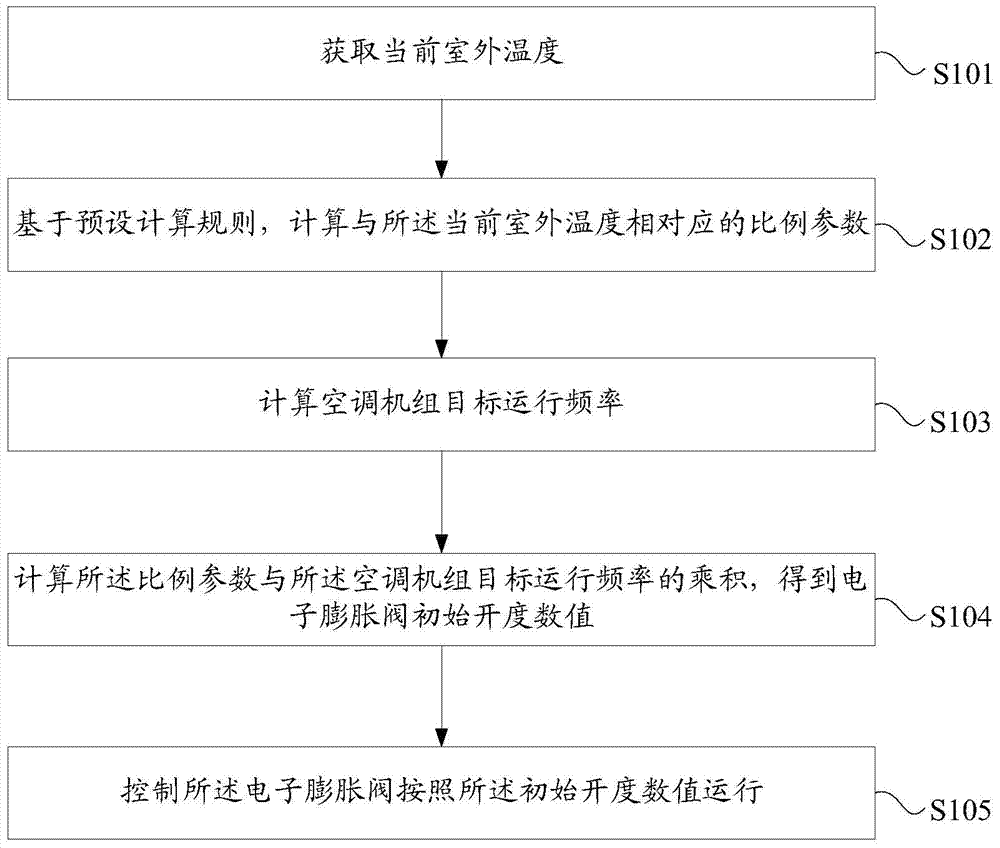

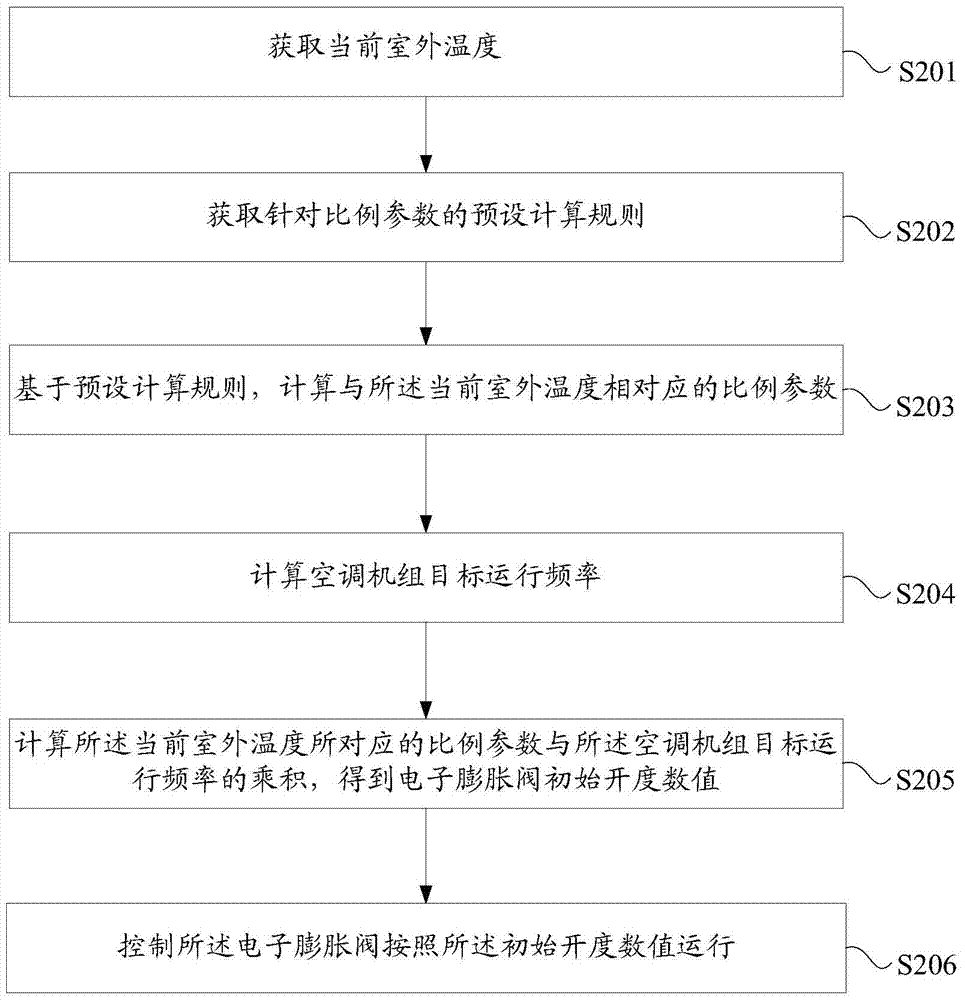

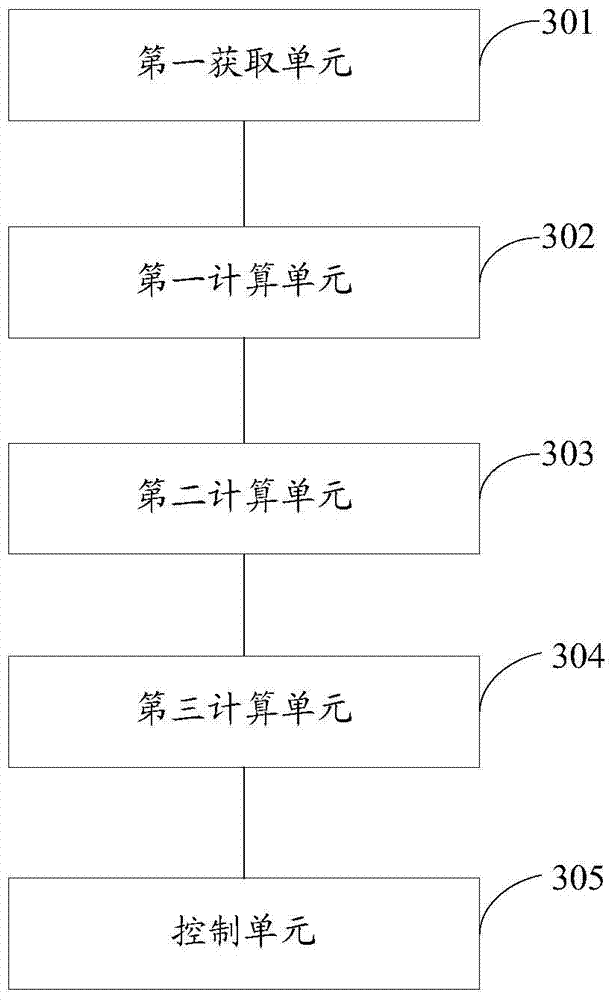

Control method, device and air conditioning system for initial opening of electronic expansion valve

ActiveCN104930772BEasy accessFast steady stateMechanical apparatusSpace heating and ventilation safety systemsStable stateOutdoor temperature

The invention discloses a control method and a device for an initial openness of an electronic expansion valve and an air conditioning system. The method comprises the steps of: obtaining a present outdoor temperature; calculating a proportional parameter corresponding to the present outdoor temperature based on preset calculation rules; calculating a target operation frequency of an air conditioning set; calculating a product between the proportional parameter and the target operation frequency of the air conditioning set to obtain an initial openness numerical value of the electronic expansion valve; and controlling the electronic expansion valve to operate according to the initial openness numerical value. The method can enable the electronic expansion valve to work according to the proper initial openness so as to help the air conditioning system to quickly enter a stable state; and compared with the prior art, a certain energy saving effect is achieved in the operation process.

Owner:GREE ELECTRIC APPLIANCES WUHAN +1

A shock-absorbing adjustment mechanism for a plane mirror

The invention discloses a shock-absorbing adjustment mechanism for a plane mirror. The plane mirror is suspended on the main structure by a thin steel belt through half-threaded bolts. The side thread adjustment rod of the plane mirror, the back adjustment mechanism, the back thread adjustment rod, and the bottom thread adjustment rod jointly realize the shock absorption and high-precision adjustment function of the plane mirror. The advantage of the shock-absorbing adjustment mechanism is that the plane mirror can quickly enter a stable state through the high-precision adjustment mechanism under the condition that the plane mirror is only slightly deformed.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

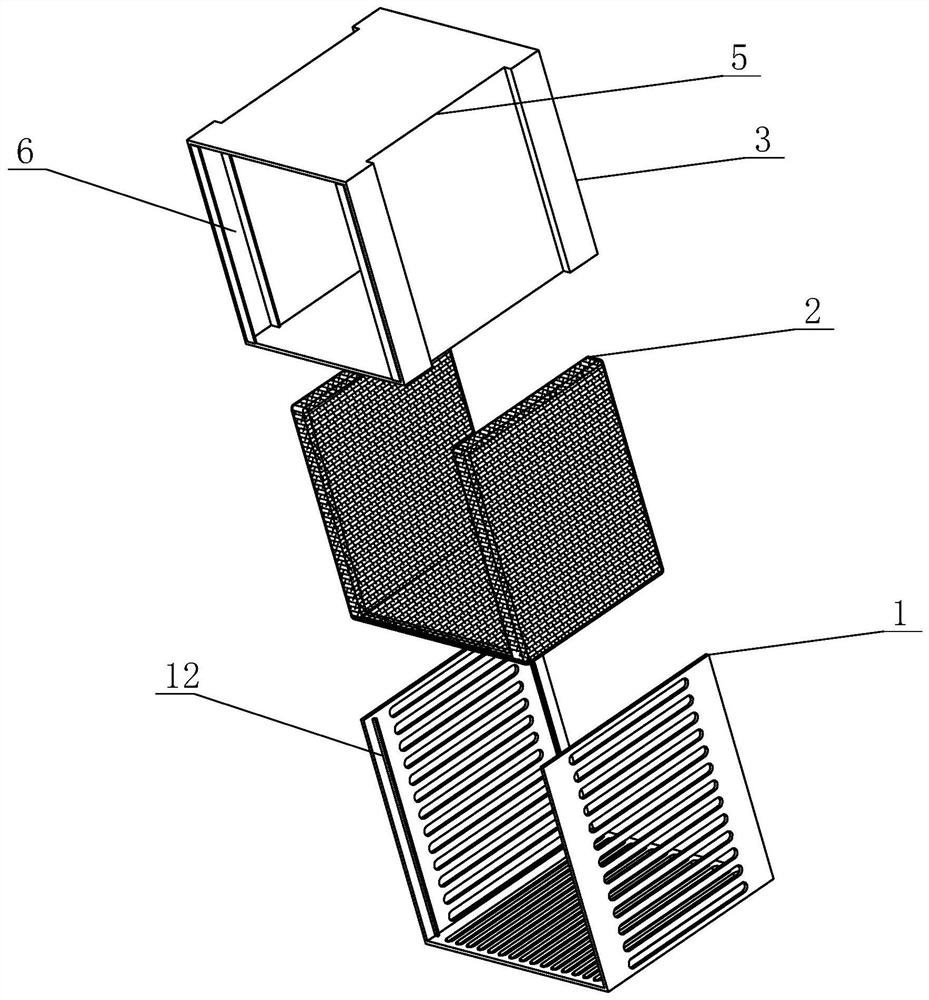

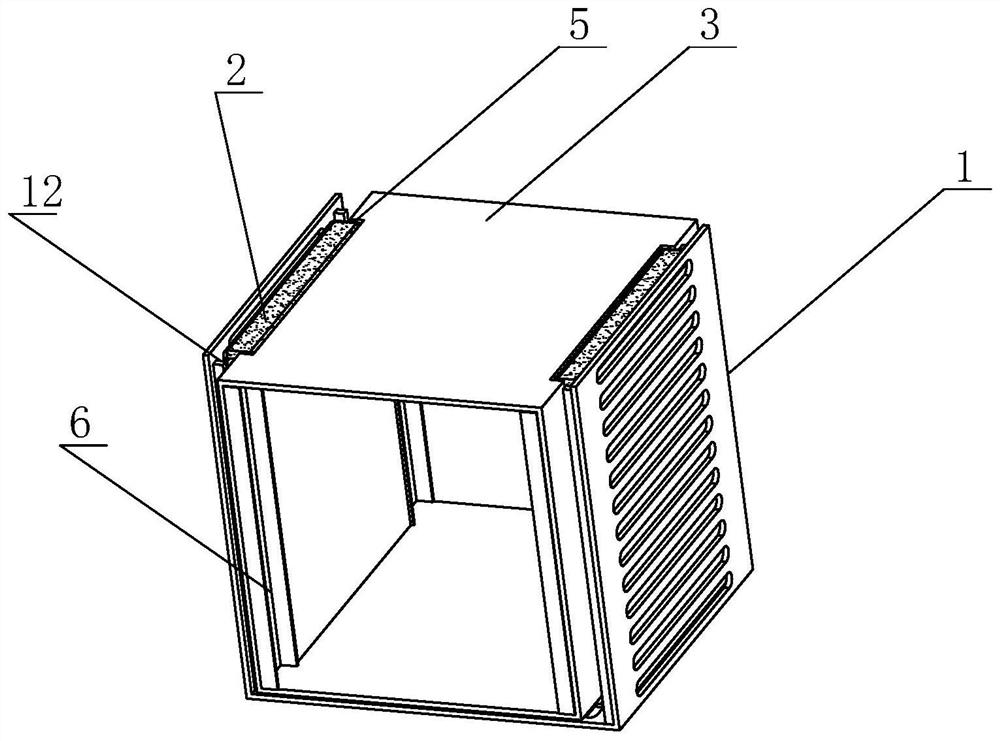

Computer hard disk quick mount shock absorber bracket

ActiveCN108491044BSolving resonance problemsSolve rigid problemsDigital processing power distributionSoftware engineeringStructural engineering

The invention discloses a computer hard disk quick-installation damping bracket and mainly relates to the field of computers. The bracket comprises a frame-shaped rack, a gasket, a double-square-shaped frame and a hard disk bracket sequentially sleeving from outside to inside, the frame-shaped rack is detachably fixed in a hard disk area of a computer cabinet, the gasket is a U-shaped metal wire wound gasket matched with the inside of the frame-shaped rack, the hard disk bracket is slidably connected with the double-square-shaped frame, multiple twisting elastic pieces are arranged at the topand the bottom of the double-square-shaped frame, the hard disc bracket is elastically connected with the double-square-shaped frame through the twisting elastic pieces, and a plurality of layers of hard disc positions are arranged on the hard disk bracket. The bracket has the advantages that the bracket can effectively absorb resonance in the cabinet, can quickly buffer and absorb violent rigid vibration caused by collision, can quickly restore stability and has good vibration-preventive protection effect on hard discs.

Owner:XUCHANG UNIV

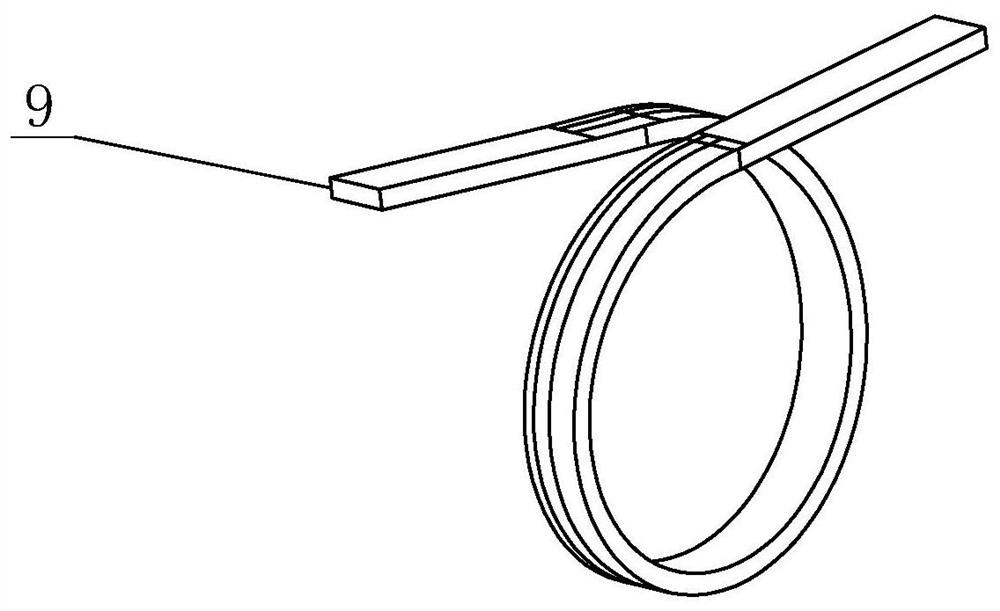

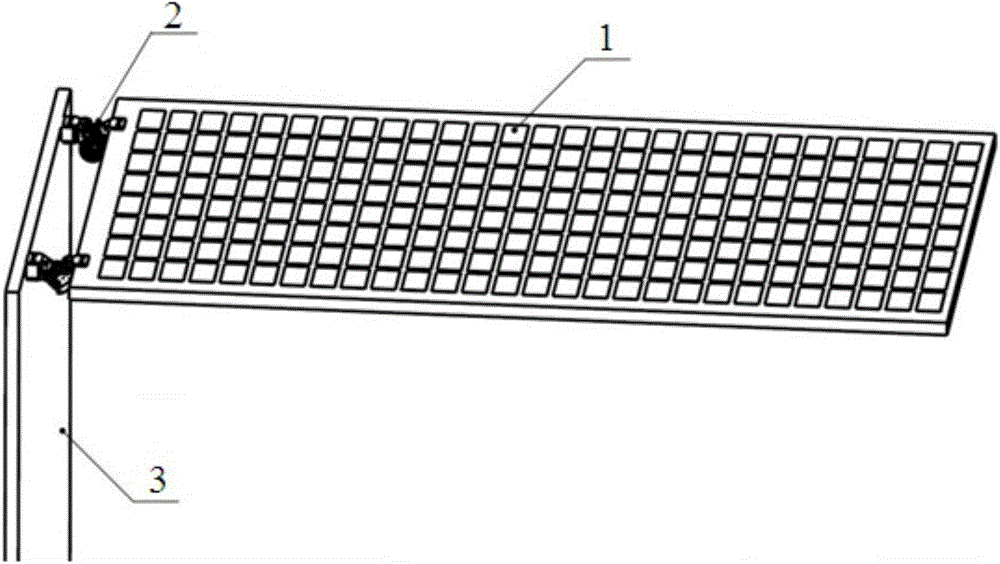

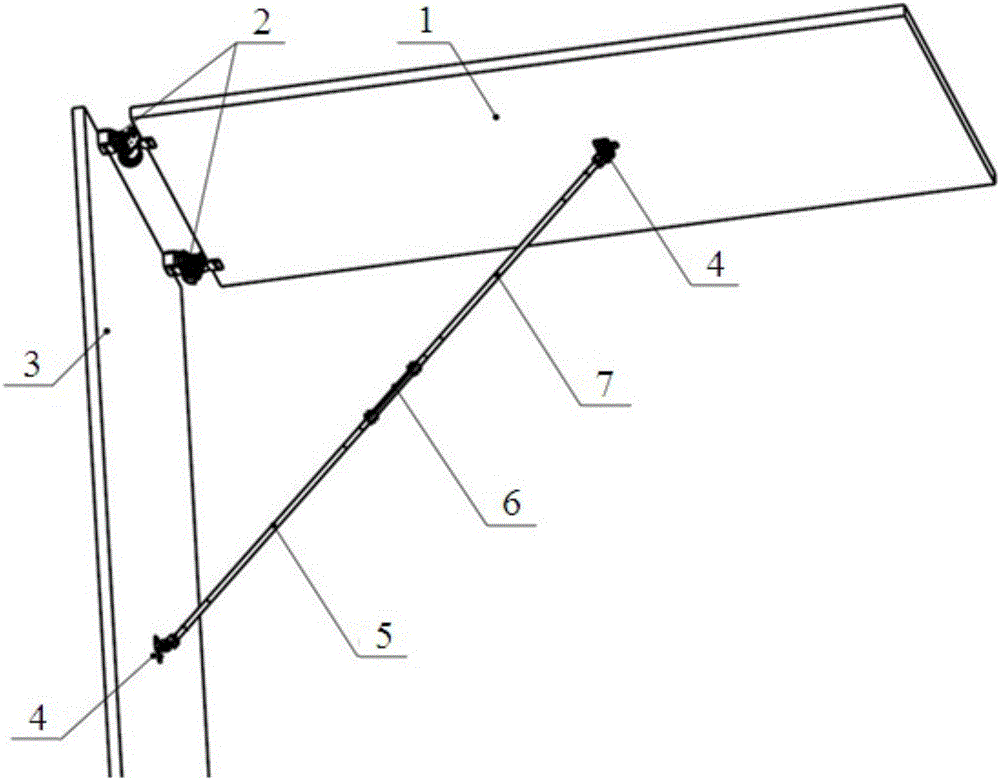

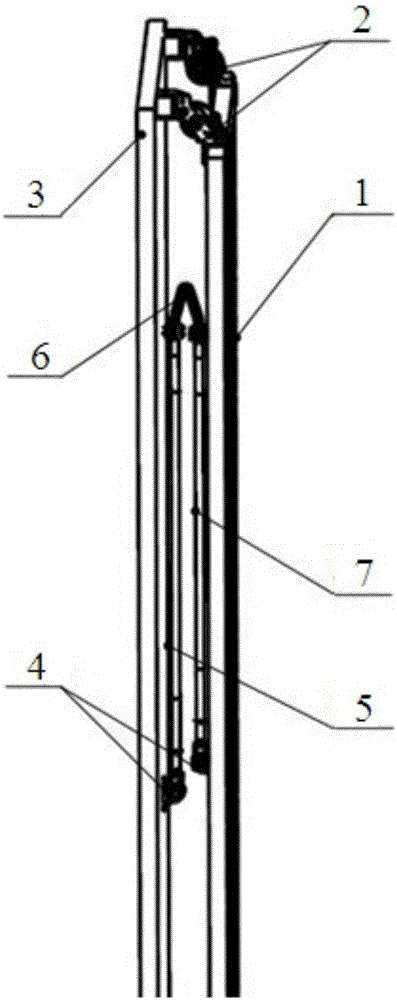

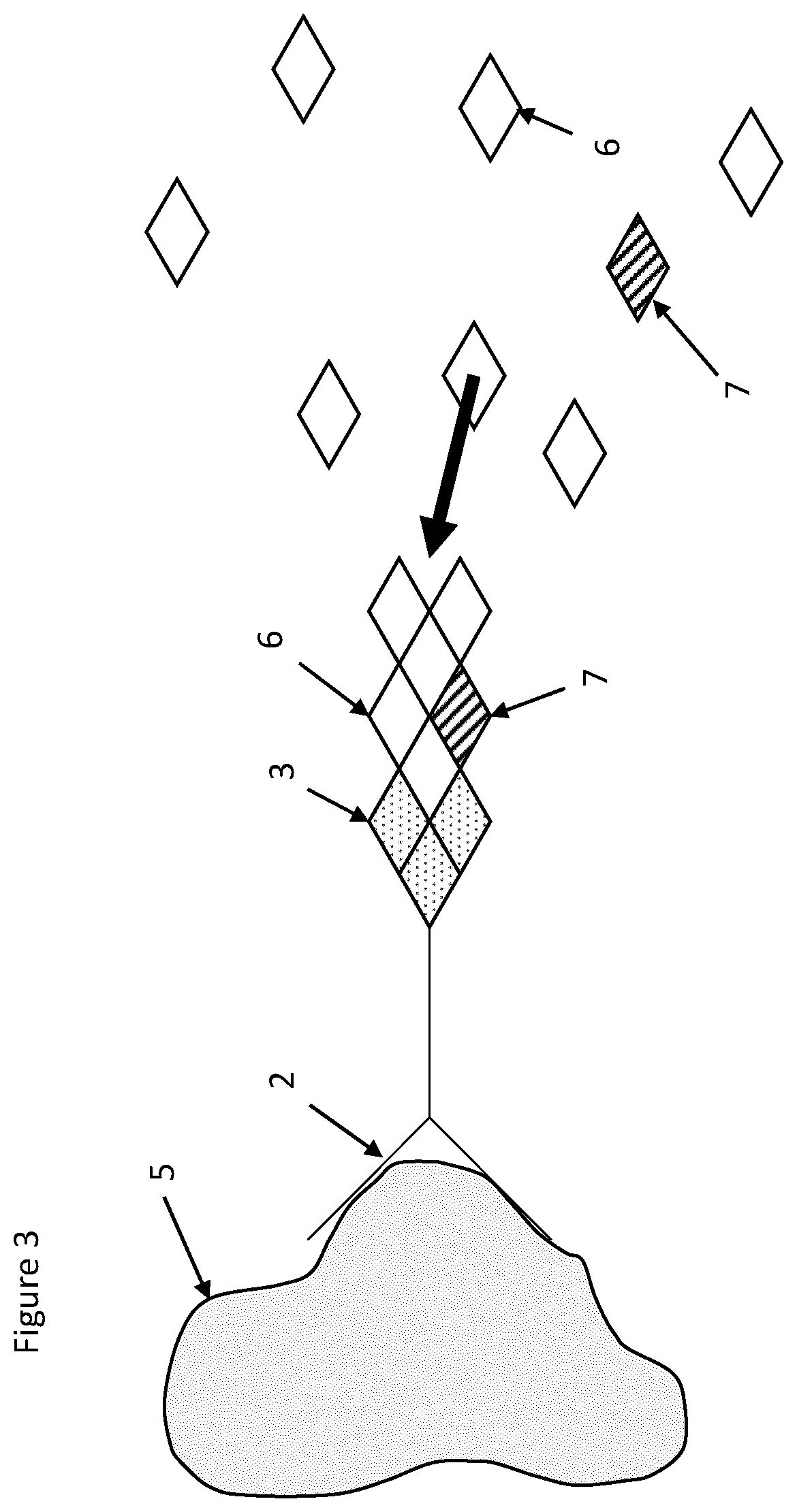

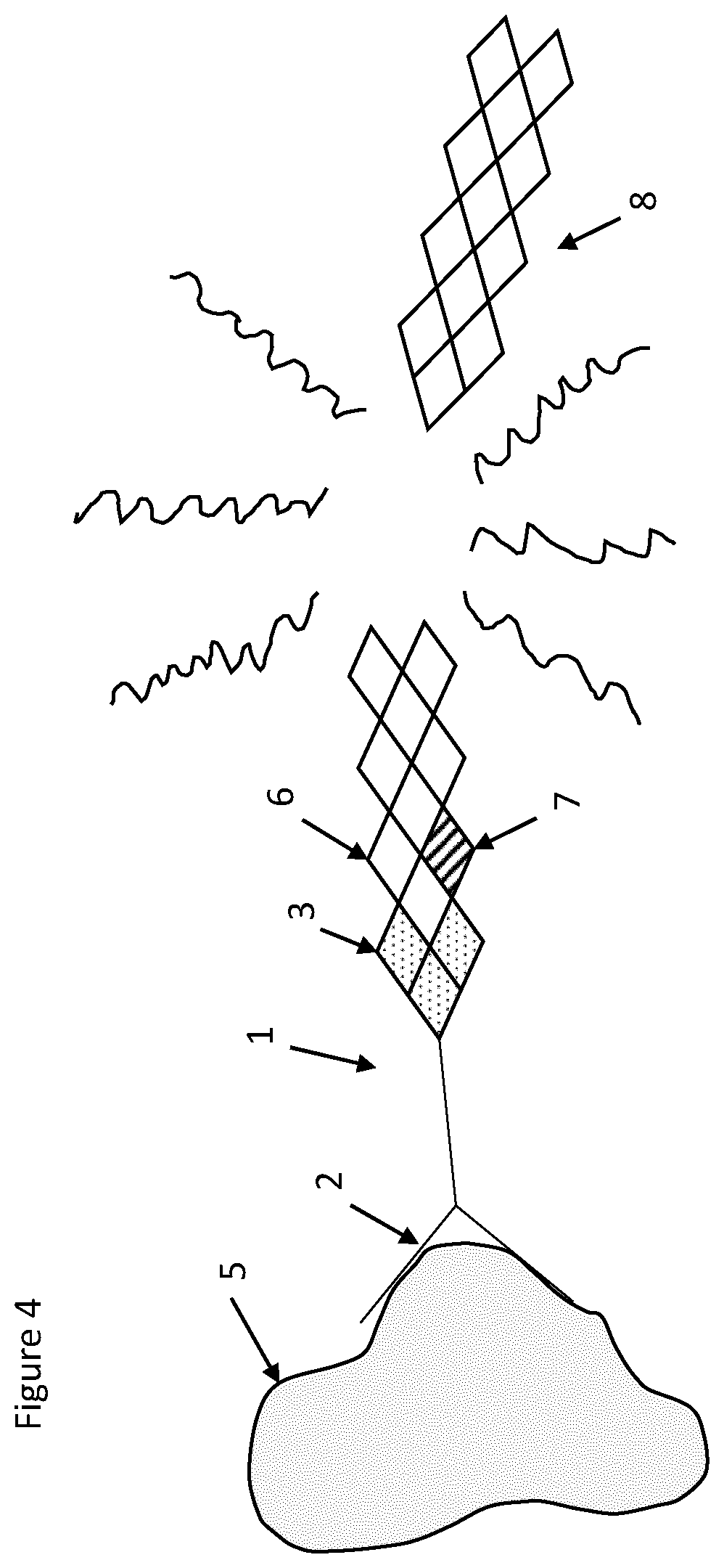

A new solar panel deployment and support mechanism based on ribbon springs

InactiveCN103482084BImprove reliabilityMeet fundamental frequency requirementsPhotovoltaic supportsCosmonautic vehiclesBand shapeCoil spring

A novel band-spring-based solar sailboard unfolding and supporting mechanism belongs to the field of unfolding mechanisms applied to satellite solar battery arrays and aims to solve the problems of low unfolding rigidity and low base frequency in the prior art. The mechanism comprises a solar sailboard, coil-spring driving hinges, a satellite body, strut hinges, a lower strut, a band spring and an upper strut; the solar sailboard and the satellite body are connected by the coil-spring driving hinges, two ends of the band spring are respectively connected with the upper and lower struts by adapters, the upper strut is connected with the solar sailboard by one strut hinge, and the lower strut is connected with the satellite body by the other strut hinge; coil springs in the coil-spring driving hinges, the band spring and the strut hinges provide unfolding moment so as to realize the unfolding of the solar sailboard. According to the novel band-spring-based solar sailboard unfolding and supporting mechanism, the solar sailboard, the satellite body and the upper and lower struts form a whole to constitute a stable supporting structure shaped like a spacial tetrahedron, so that the base frequency and the rigidity of a system under an unfolding state are improved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

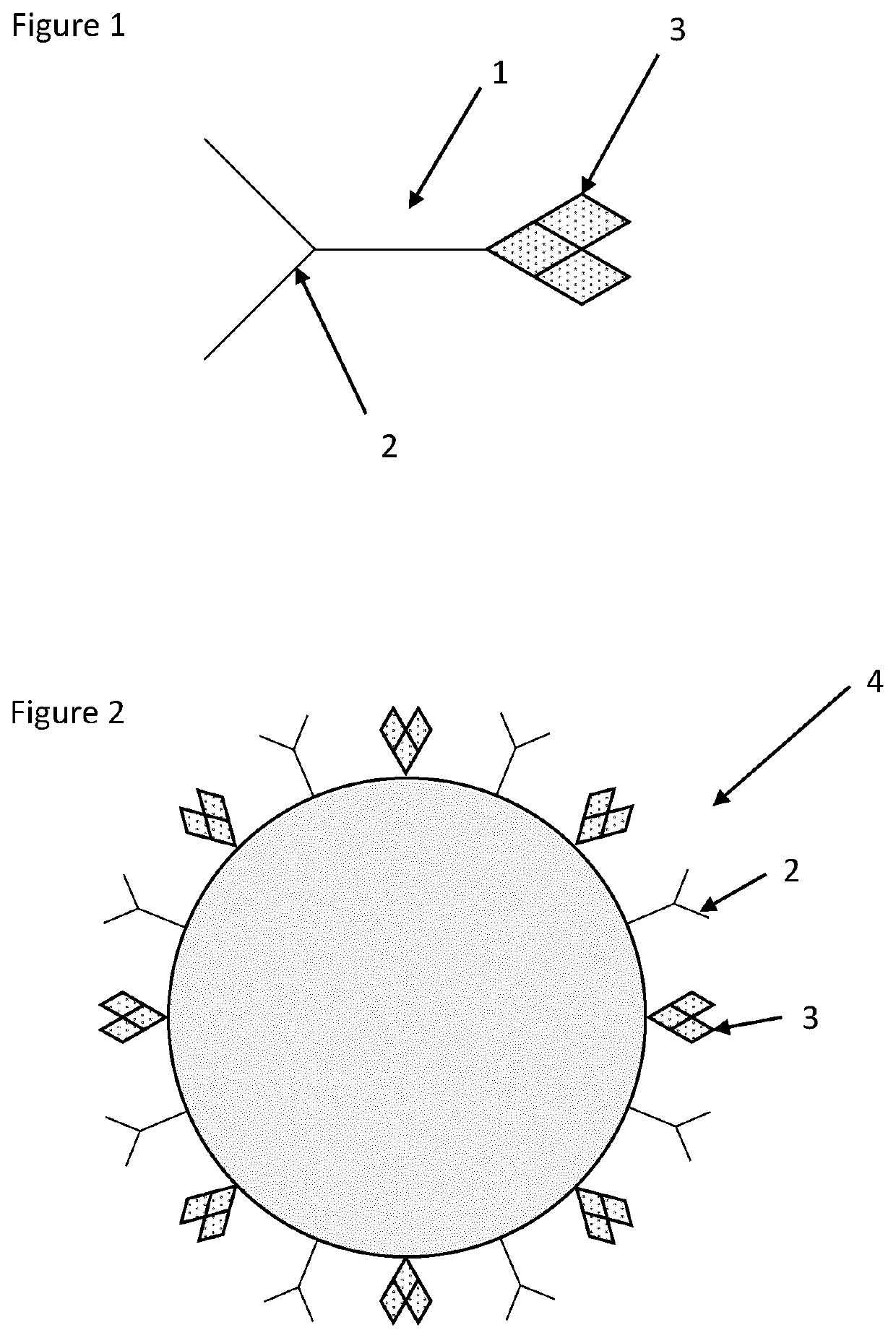

Detection and Quantification of Molecular Species

PendingUS20220163537A1Reduce in quantityImprove responseBiological material analysisBiological testingPolymer scienceBiopolymer

The invention relates to a conjugate comprising a binding element and a self-polymerising biopolymer. The invention also relates to a kit comprising the conjugate and self-polymerising biopolymer subunits. The invention also relates to a method of using the conjugate to measure the concentration of a target substance comprising binding the conjugate to the substance, isolating the bound conjugate, polymerising biopolymer filament, and calculating the concentration of the target substance.

Owner:FAST BT UG

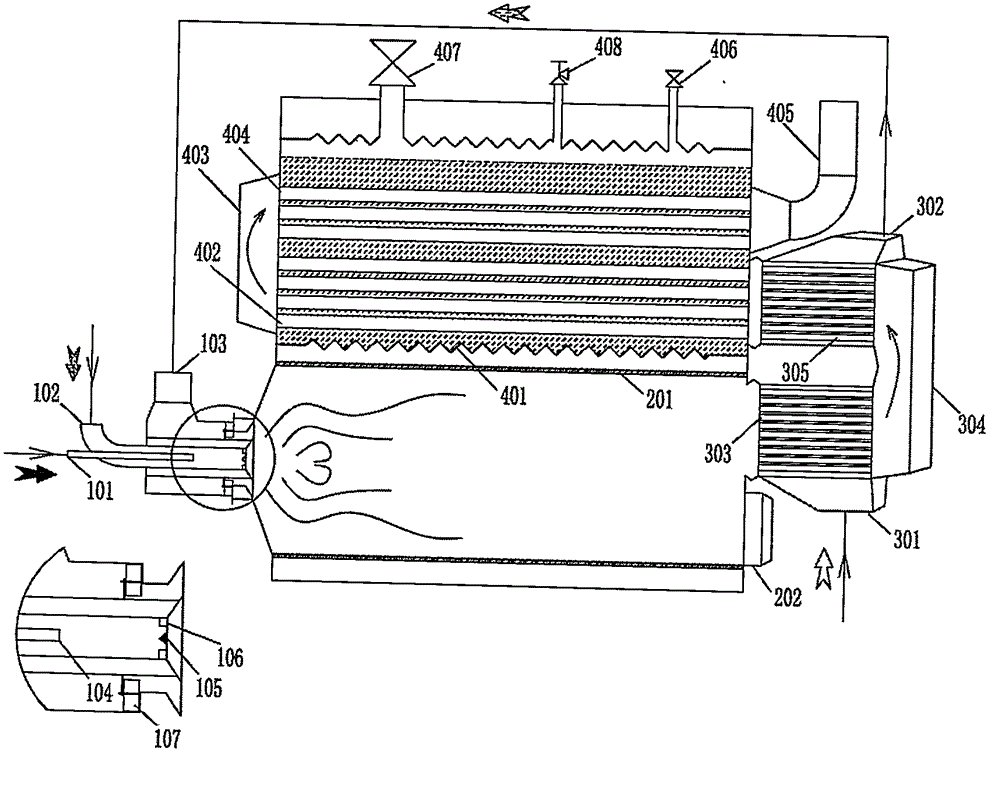

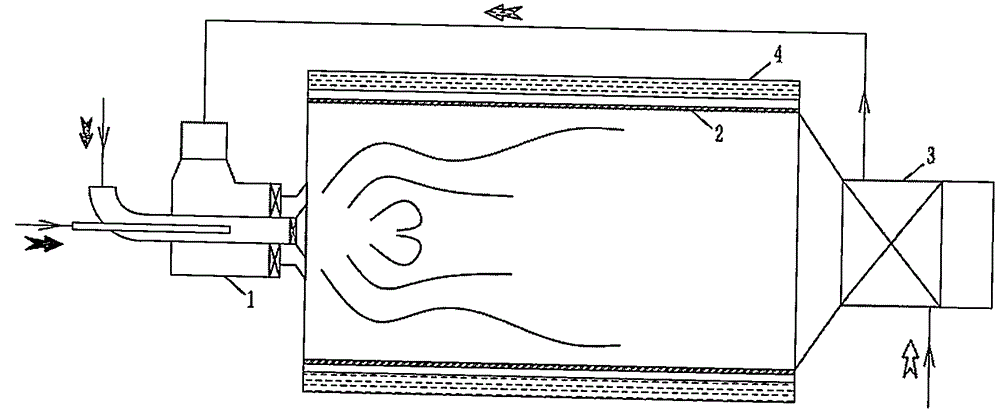

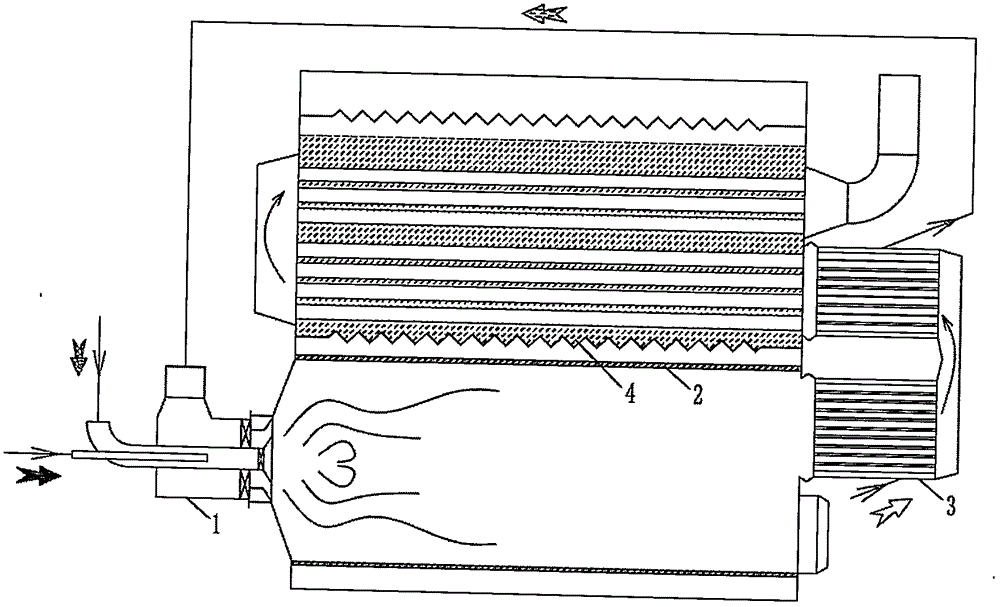

Rapid combustion type industrial powder combustion system

InactiveCN105987380AFully stable combustionPromote fireCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelAir preheaterCombustion system

A rapid combustion type industrial powder combustion system is characterized by comprising a gas-solid premixing combustor, a heat-resistant steel hearth and a high-temperature air preheater. By means of the system, pulverized coal is rapidly ignited, stably combusted and thoroughly combusted in an industrial boiler. A combustion method is provided for clean utilization of coal in the field of the industrial boiler.

Owner:上海谊快能源技术有限公司

Method and device for suppressing residual vibration of boom

ActiveCN103629293BReduce vibration amplitudeFast steady stateVibration suppression adjustmentsStable stateResidual vibration

The invention provides a method and a device for suppressing residual oscillation of a cantilever crane, which are applied to an engineering machine. The engineering machine comprises the cantilever crane and an actuating mechanism for controlling the movement of the cantilever crane. The method comprises the following steps of acquiring indication information reflecting the oscillation amplitude of the cantilever crane; determining the oscillation situation of the cantilever crane according to the variation trend of the indication information, wherein the oscillation situation comprises the oscillation direction of the cantilever crane; controlling the actuating mechanism to apply the interference force for reducing the oscillating amplitude of the cantilever crane onto the cantilever crane in the current oscillation direction of the cantilever crane according to the oscillation situation under the situation that the cantilever crane stops movement and the residual oscillation of the cantilever crane is started. By utilizing the technical scheme, the technical problems in the prior art that the time for stabilizing the cantilever crane is long, the residual oscillation amplitude is large and the like can be solved, so that the cantilever crane can be rapidly stabilized after the variable-amplitude movement is stopped, and the working efficiency is improved.

Owner:ZOOMLION HEAVY IND CO LTD

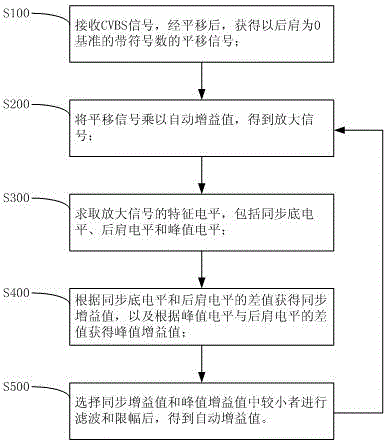

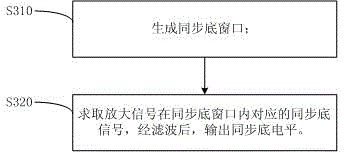

Automatic gain control method and device for CVBS (Composite Video Broadcast Signal)

ActiveCN105812763AViewing effect is not affectedFast steady stateColor signal processing circuitsBrightness and chrominance signal processing circuitsStable stateAutomatic train control

The invention discloses an automatic gain control method and device for a CVBS (Composite Video Broadcast Signal). The method comprises the steps of receiving a CVBS, and performing translation to obtain a translation signal of which the back porch is a 0-based signed number; multiplying the translation signal by an automatic gain value to obtain an amplified signal; solving the feature level of the amplified signal, acquiring a synchronous gain value and a peak gain value, performing filtration and amplitude limitation on the smaller value to obtain the automatic gain value, returning to the front step, and multiplying the translation signal by the automatic gain value. The acquired automatic gain value is more accurate by solving the feature level of the CVBS, and the method and the device is not only suitable for automatic gain control of normal CVBS but also suitable for automatic gain control of nonstandard signals, so that the overall watching effect of images is not influenced. In addition, automatic gain adjustment is quickly performed in view of the initial state during startup or plug-unplug of the system, so that images can reach the stable state more quickly, and long-time white or dark images do not appear.

Owner:ARKMICRO TECH

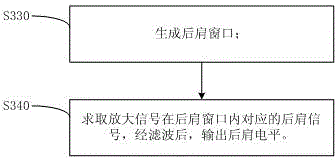

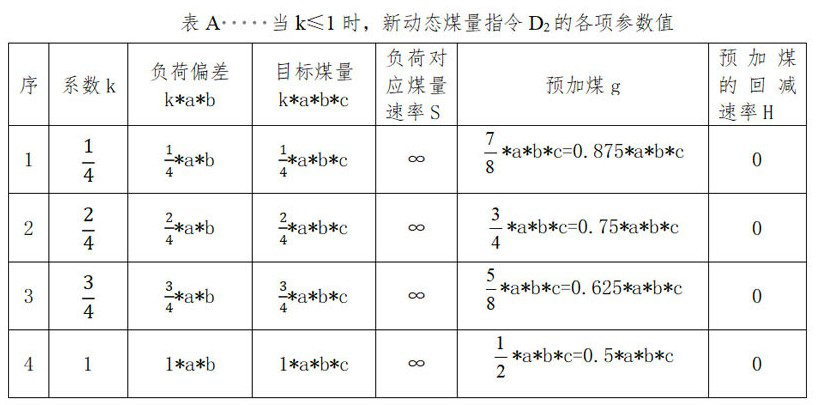

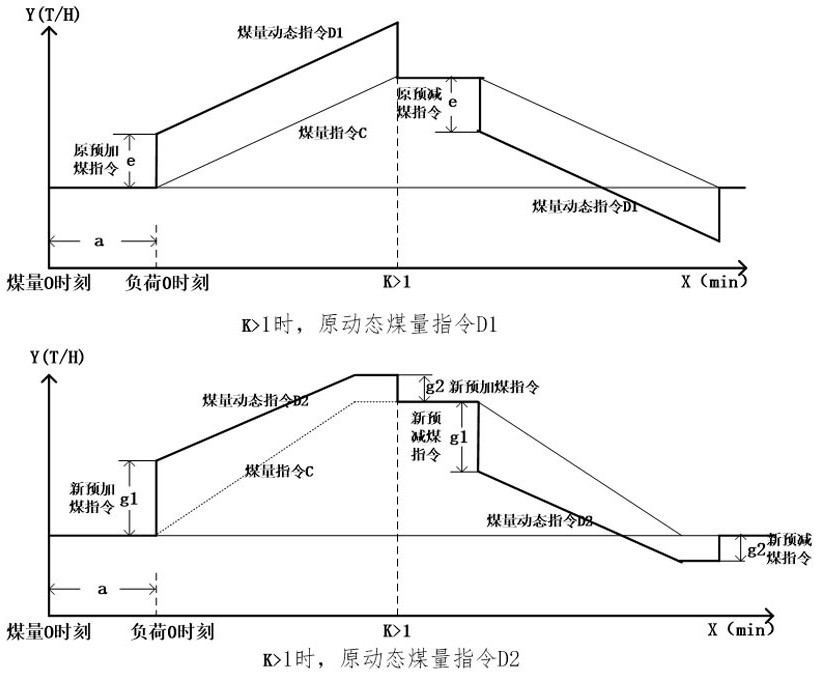

Coal quantity instruction optimization method for supercritical frequency modulation and peak regulation thermal power generating unit

PendingCN113852096AStep reductionFast steady stateSingle network parallel feeding arrangementsPower oscillations reduction/preventionThermodynamicsProcess engineering

The invention relates to the technical field of thermal power generating unit coal quantity instruction optimization methods, and concretely relates to a coal quantity instruction optimization method for a supercritical frequency modulation and peak regulation thermal power generating unit. Adynamic coal quantity instruction is obtained according to the following method: when k is less than or equal to 1, a dynamic coal quantity instruction D2 is a pulse coal quantity instruction g plus a coal quantity instruction c; and when k is greater than 1, the dynamic coal quantity instruction D2 is the sum of the trapezoidal coal quantity instruction and the coal quantity instruction c. According to the dynamic coal quantity instructions obtained through the optimization method, when k is smaller than or equal to 1, the pre-coaling instruction is a pulse coal quantity instruction g, when k is larger than 1, the pre-coaling instruction is a trapezoidal coal quantity instruction, the step amount of the pre-coaling instruction is reduced, the coal quantity instruction of the frequency modulation and peak regulation thermal power generating unit reaches a target value in an optimal mode, and the unit can quickly enter a stable state.

Owner:ELECTRIC POWER SCI RES INST OF STATE GRID XINJIANG ELECTRIC POWER +2

Method of using sma wire to drive moving parts

ActiveCN109960001BImprove work efficiencyFast steady stateTelevision system detailsColor television detailsEngineeringMoving parts

Owner:NINGBO SUNNY OPOTECH CO LTD

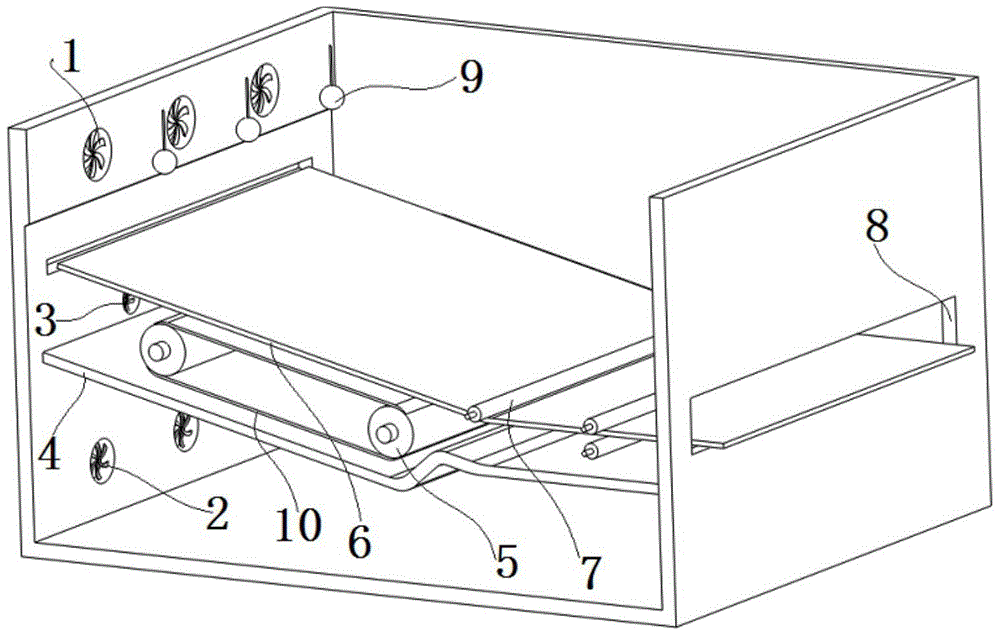

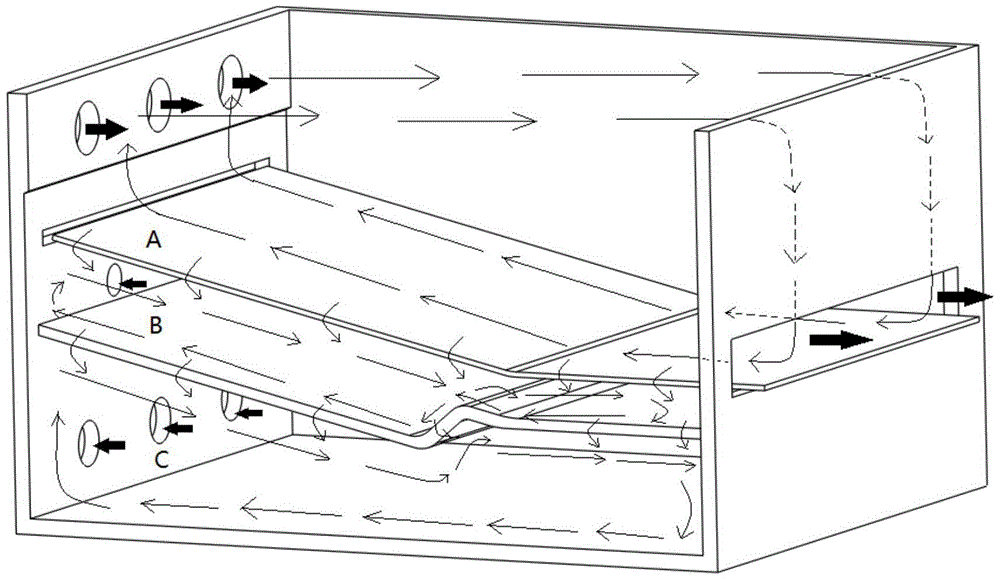

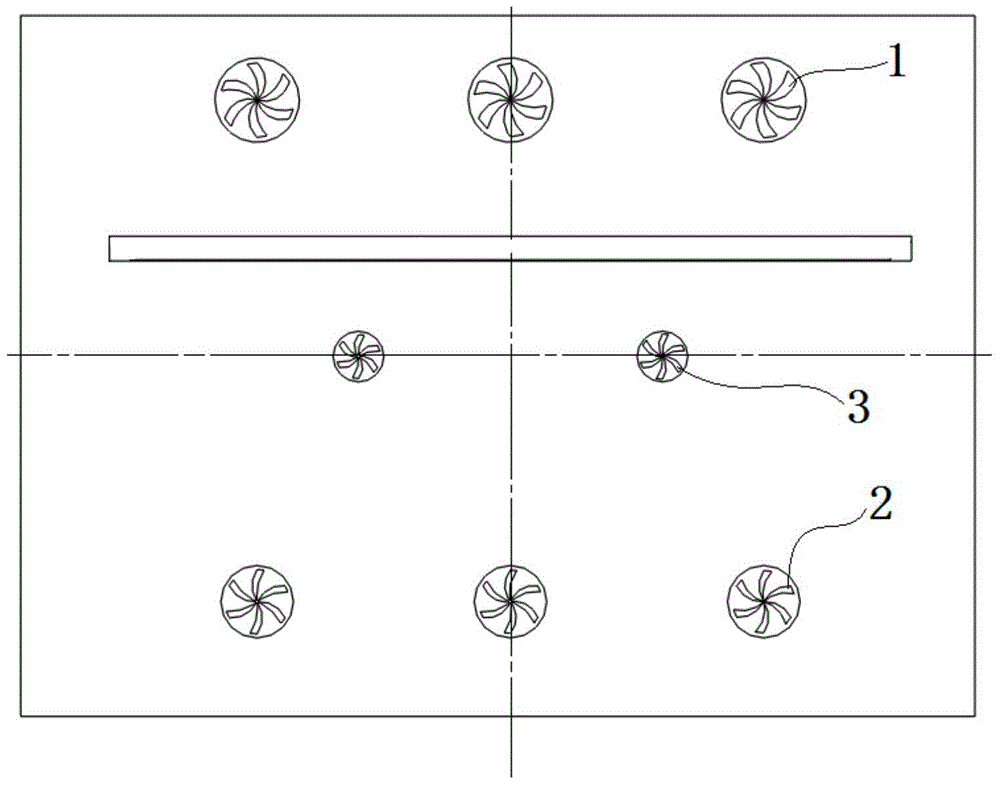

A drying room of a rotary screen printing machine

ActiveCN104723669BPromote natural ventilationFast steady statePrinting press partsScreen printingConduction band

The invention discloses a drying room of a circular screen printer. The drying room of the circular screen printer comprises draught fans, heat sources, a conduction band, a conduction band roller, cloth press rollers, an air outlet and a baffle, wherein the area of the drying room is divided into an upper area, a middle area and a lower area by fabric and the baffle; the drought fans are of three different types, the number of the drought fan of the largest type is three, and the drought fans of the largest type have an air blowing function and are located in the area formed by the fabric and the upper portion of the drying room, the number of the drought fans of the middle type is three, the drought fans of the middle type have an air suction function and are located in the area formed by the baffle and the lower portion of the drying room, the number of the drought fans of the smallest type is two, and the drought fans of the smallest type have the air suction function and are located in the area formed by the baffle and the fabric; the number of the heat sources is three, the heat sources are fixedly hung on the room top of the drying room through small metal bars, and the positions of the heat sources correspond to three air blowers; the combination body of the conduction band and the conduction band roller is arranged in an inclined direction and forms a 30-degree angle with the horizontal plane, the number of the cloth press rollers is three, and the cloth press rollers are located on the downstream in the running direction of the fabric; the baffle is connected with the front face and the back face of the drying room, and gaps are formed between the baffle and the left face and the right face of the drying room; and the air outlet is communicated with an fabric outlet.

Owner:黄红兵

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com