Rapid combustion type industrial powder combustion system

A combustion system and industrial technology, applied to the combustion of block fuel and liquid fuel, the combustion of block fuel and powder fuel, the combustion of gaseous fuel and powder fuel, etc., which can solve the problem of insufficient combustion air and small boilers , unable to burn low-volatile coal, etc., to achieve the effect of less heat storage and faster temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention are described in detail below, and the present embodiment is carried out under the premise of the present invention, has provided detailed implementation and specific operation process, but protection scope of the present invention is not limited to following embodiment .

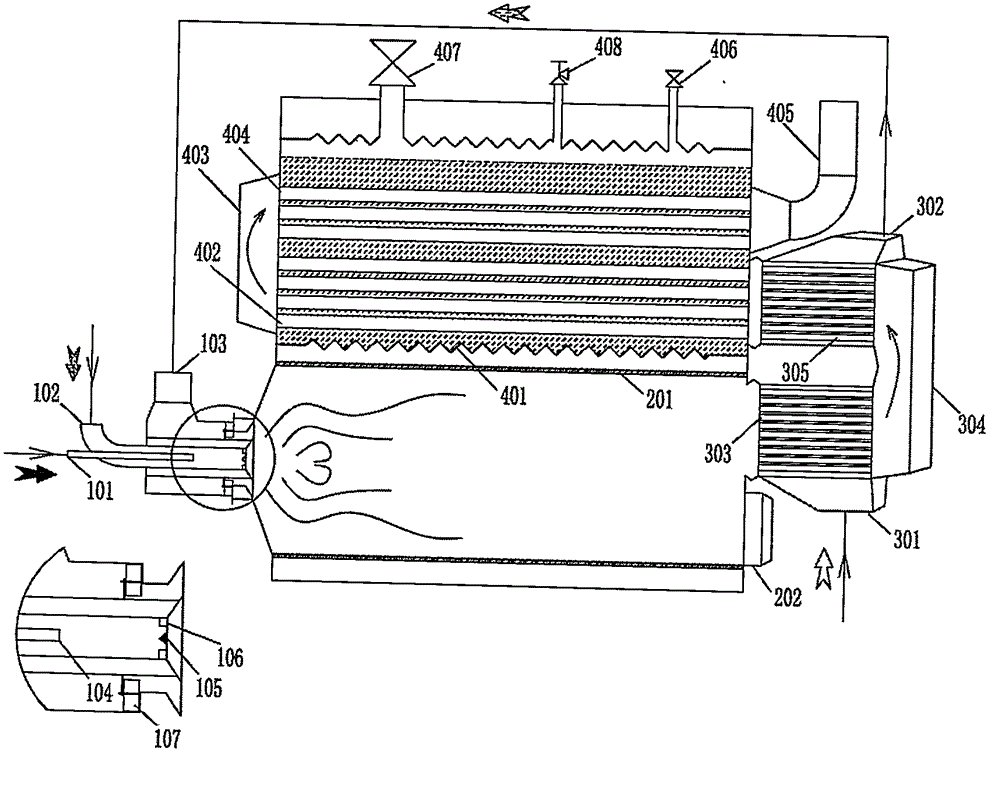

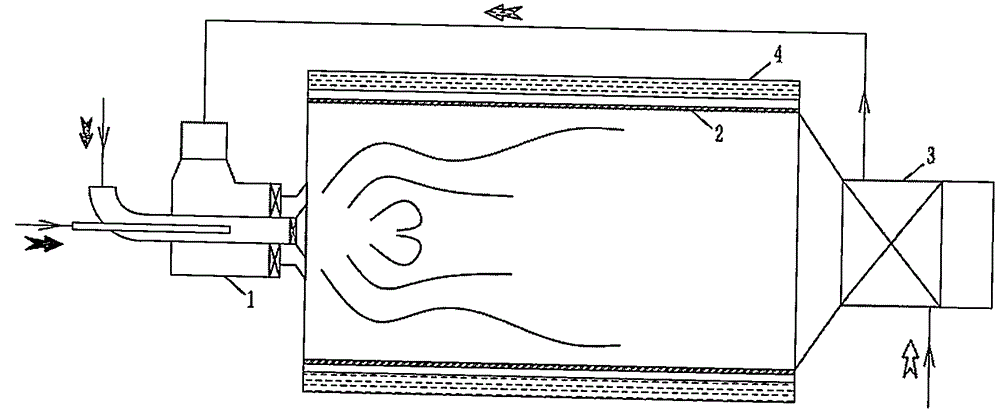

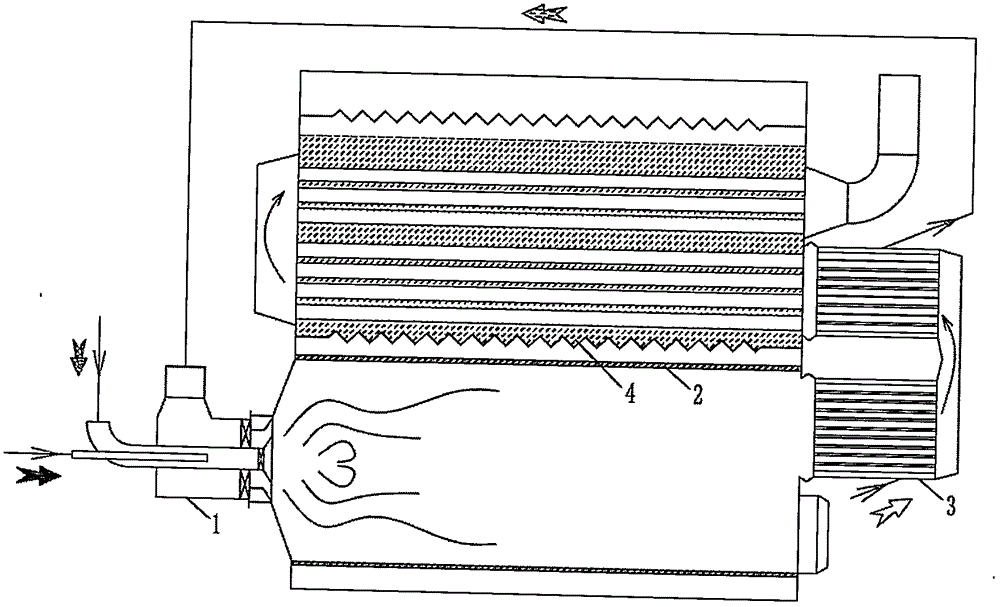

[0020] Such as Figure 4 As shown, this implementation case includes: a gas-solid premixed burner 1, a heat-resistant steel furnace 2, a high-temperature air preheater 3, and a boiler furnace 4.

[0021] The gas-solid premix burner 1 includes: a gas inlet 101 , a primary air inlet 102 , a secondary air inlet 103 , a gas nozzle 104 , an outlet blunt body 105 , swirl vanes 106 , and a swirler 107 .

[0022] The heat-resistant steel furnace includes: a heat-resistant steel cylinder 201 and an ash discharge hole 202 .

[0023] The high-temperature air preheater 3 includes: an air inlet 301 , an air outlet 302 , a first tube layer 303 , a turning chamber 304...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com