Improvements in controlling internal combustion engine emissions

An internal combustion engine, engine technology, applied in the direction of internal combustion piston engine, combustion engine, engine control, etc., can solve the problem of effective working delay of the catalytic converter, and achieve the effect of short duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

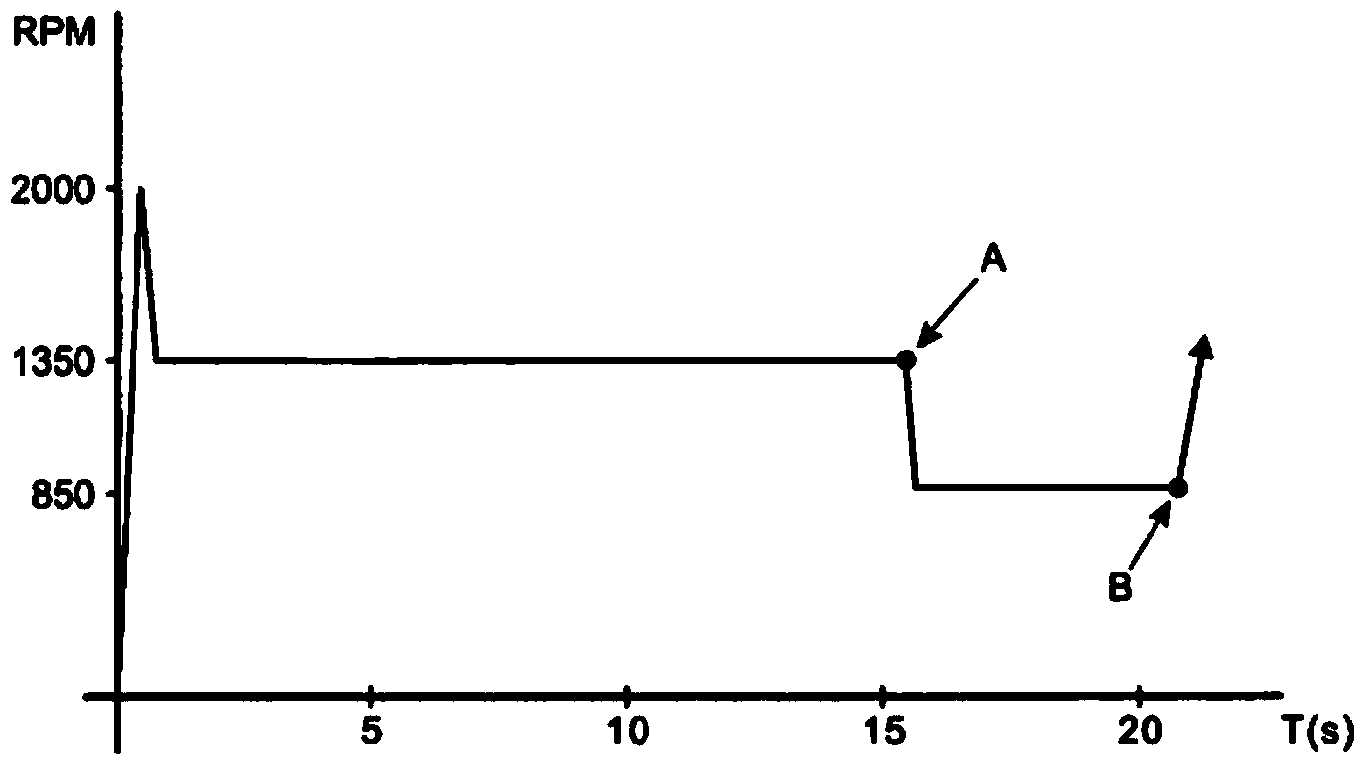

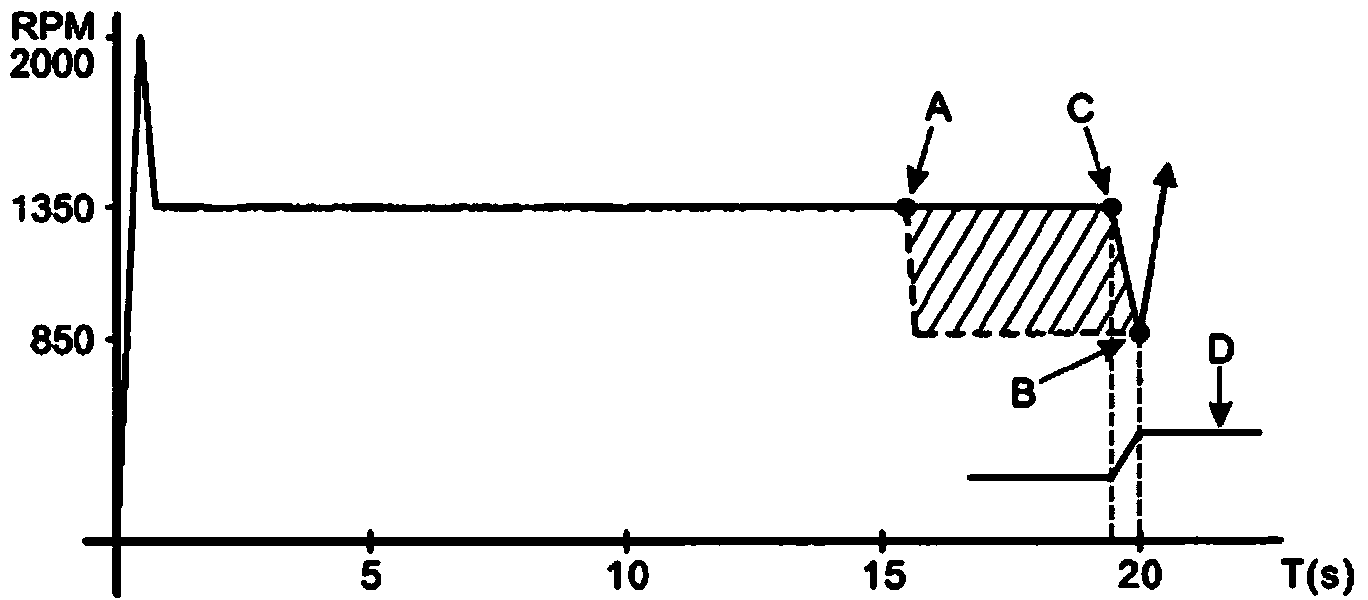

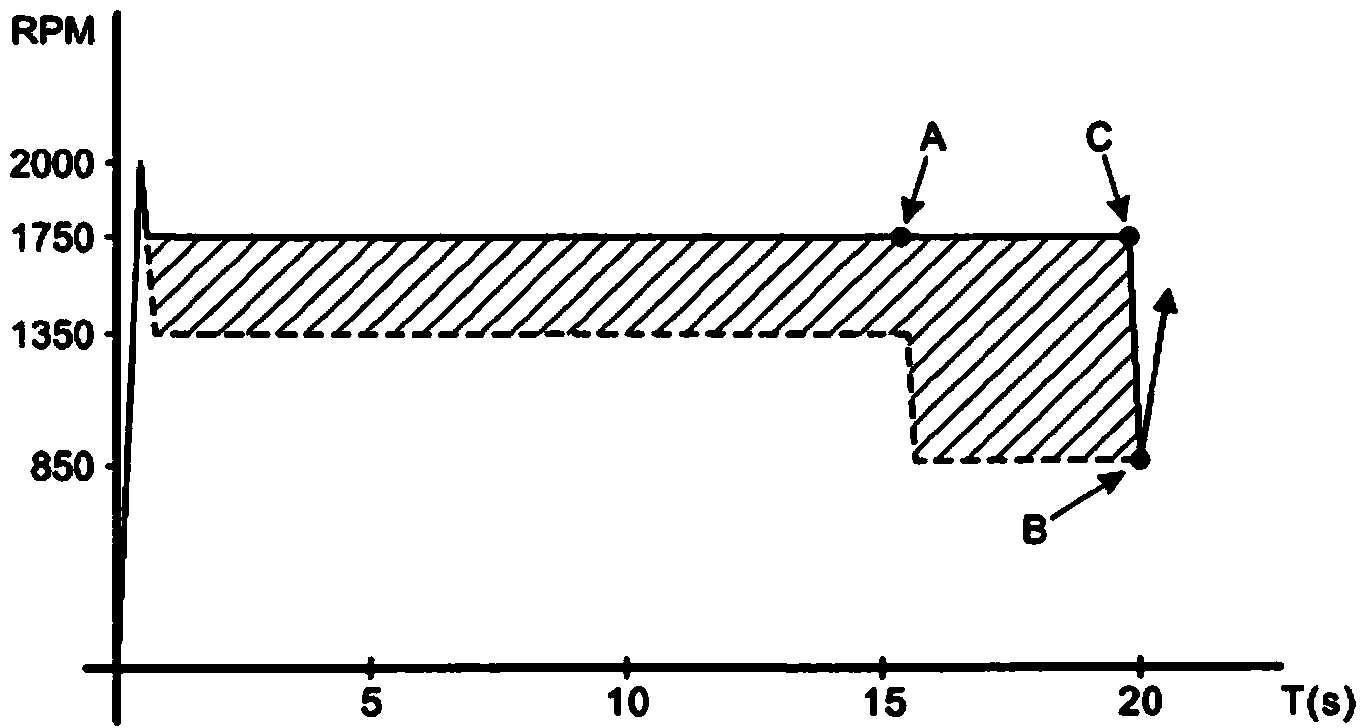

[0032] refer to figure 1 A conventional engine cold start for an electronically controlled internal combustion engine typically has an initial engine speed of 2000 rpm (revolutions per minute), which drops almost immediately to a fast idle of 1350 rpm. The fast idle is maintained from start up until about 15 seconds in order, for example, to stabilize the combustion. When the driveline is selected and engaged, the idle speed then decreases at A to approximately 850 rpm, which is an appropriate speed for the driver to drive away smoothly and gradually. The start of the vehicle - ie drive away - is at B, usually after the next time period of about 5 seconds.

[0033] In any automatic or automated powertrain, the controller will select the appropriate starting gear in response to driver commands. Typically, the driver will select a low or drive gear out of park or neutral. Typically, starting of the vehicle's engine is inhibited unless Park is selected, and activation of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com