Spherical Grinder

A grinding machine and grinding head technology, applied in the grinding field, can solve the problems of low efficiency, time-consuming and labor-intensive, etc., and achieve the effect of avoiding direct transmission, reducing production costs, and achieving the best grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

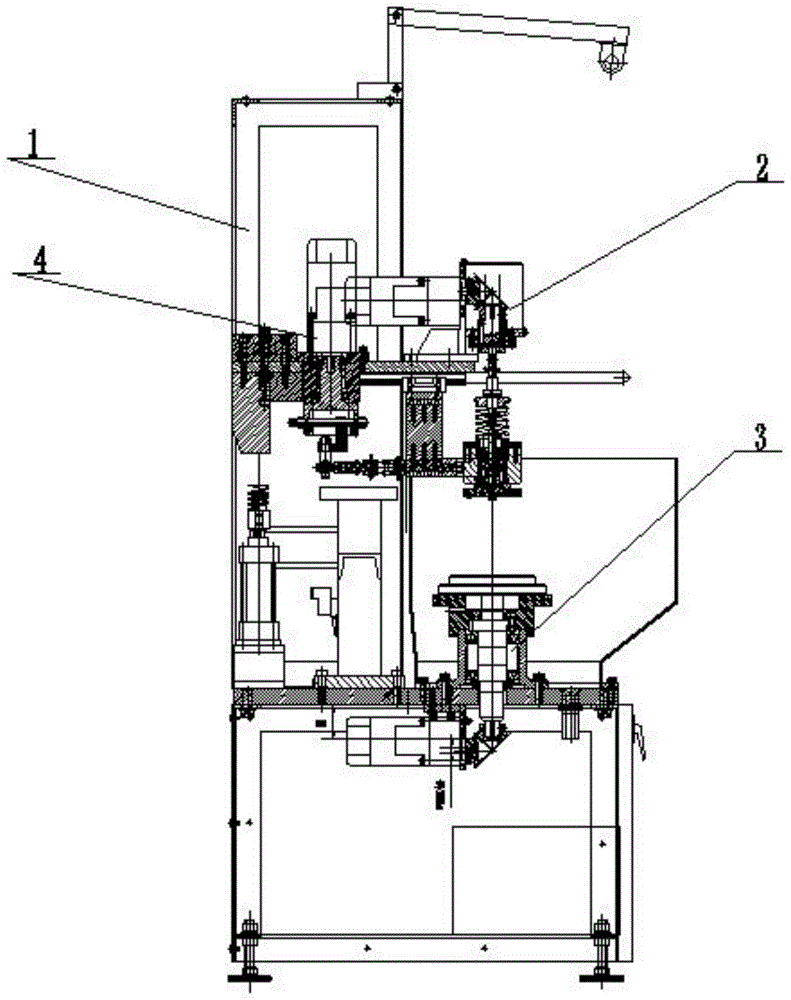

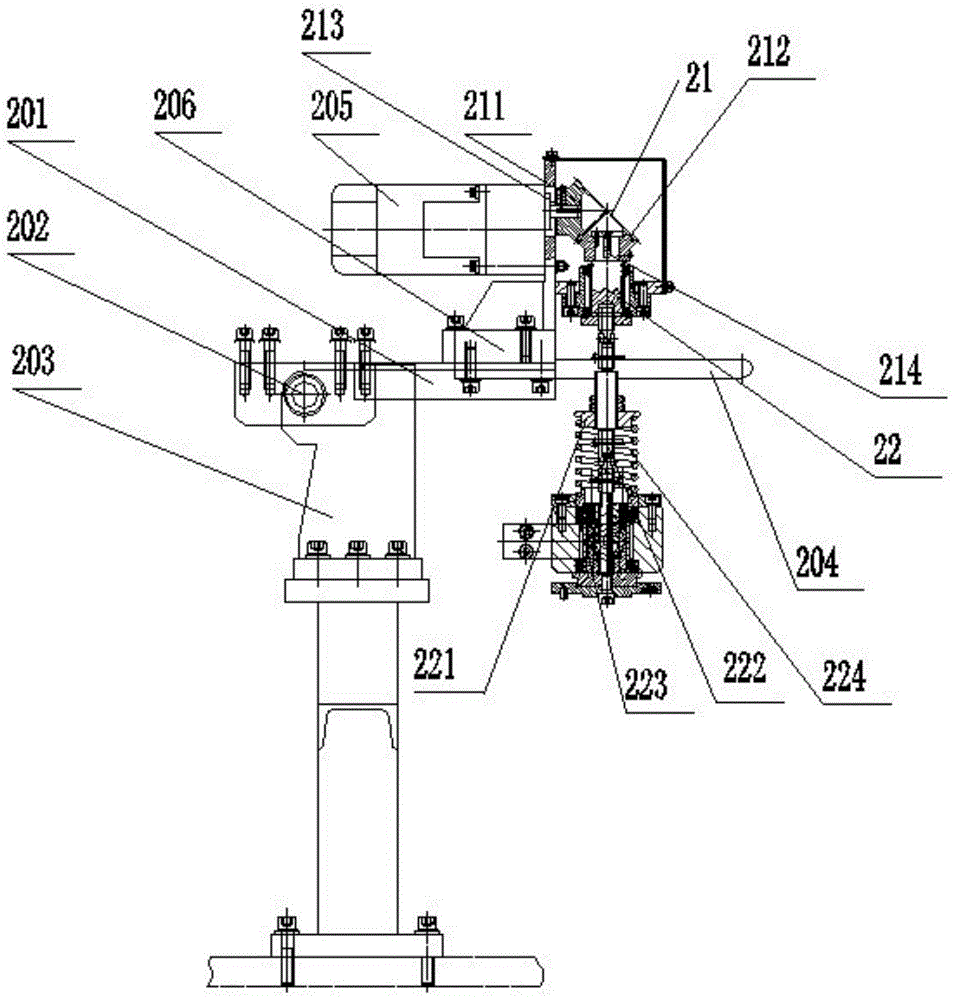

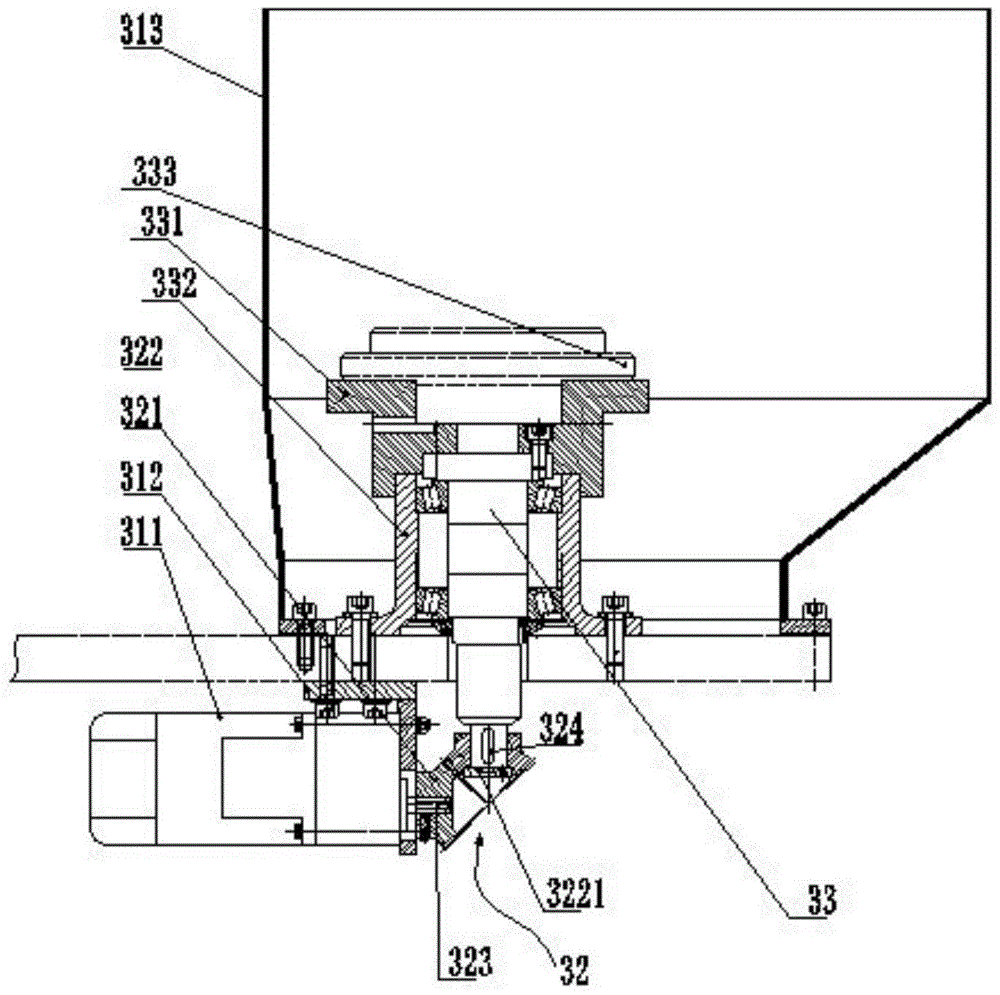

[0022] This example Figure 1 to Figure 5 A spherical grinding machine is shown, which includes a frame 1, which is characterized in that an upper grinding head assembly 2 is arranged above the frame 1, and a lower grinding head assembly is arranged corresponding to the lower part of the upper grinding head assembly 2. 3. The upper grinding head assembly 2 and the lower grinding head assembly 3 move relative to each other to grind the workpiece surface, and the upper grinding head assembly 2 is connected with an upper grinding head assembly swing mechanism 4, wherein:

[0023] The upper grinding head assembly 2 includes a flat drag 201, the flat drag 201 is rotated on the supporting plate bracket 203 through the supporting plate rotating ear 202, and one end of the flat draggi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com