Combination tool and method for installing and detaching engine piston and flame ring

A flame ring and engine technology, applied in the field of machinery, can solve the problems of lack of disassembly of the flame ring, difficulty in disassembly of the flame ring, easy wear and tear of the flame ring, etc., and achieves the effects of improved work efficiency, low labor intensity, and simple and fast operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described with reference to the drawings and specific embodiments.

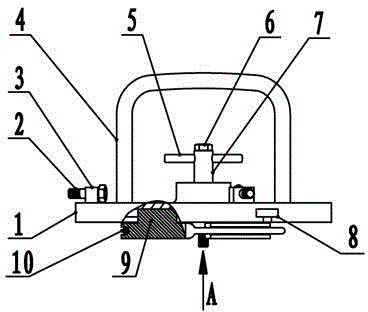

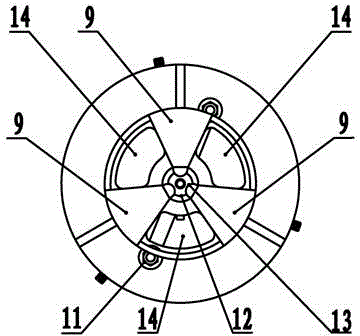

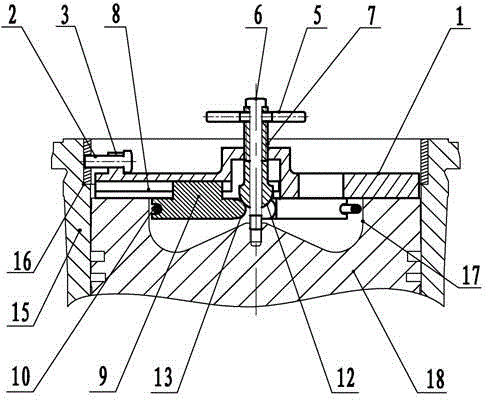

[0034] Such as figure 1 , 2 As shown, a combined disassembly tool for an engine piston and a flame ring mainly includes: a support body, a piston tightening device, a flame ring disassembly device, and the like. The support body is composed of a support plate 1 , a handle 4 and a nut 11 . The support plate 1 is disc-shaped, with three fan-shaped weight-reducing holes 14 evenly distributed on it, a boss in the center of the upper end surface, and the center of the boss is a threaded hole, and three holes are evenly distributed on the lower end surface of the support plate 1 along the circumferential direction. T-shaped guide groove 8 and a pair of stepped holes; the handle 4 is U-shaped with a circular cross-section, and the two ends of the handle 4 have a section of thinner external thread, and the two ends pass through a hole on the end surface of the support plate 1 Fix th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com