A method of making a corrugated sheet

A production method, wave-shaped technology, applied in chemical instruments and methods, wood processing equipment, lamination equipment, etc., can solve single problems, and achieve the effect of simple process and good surface touch feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

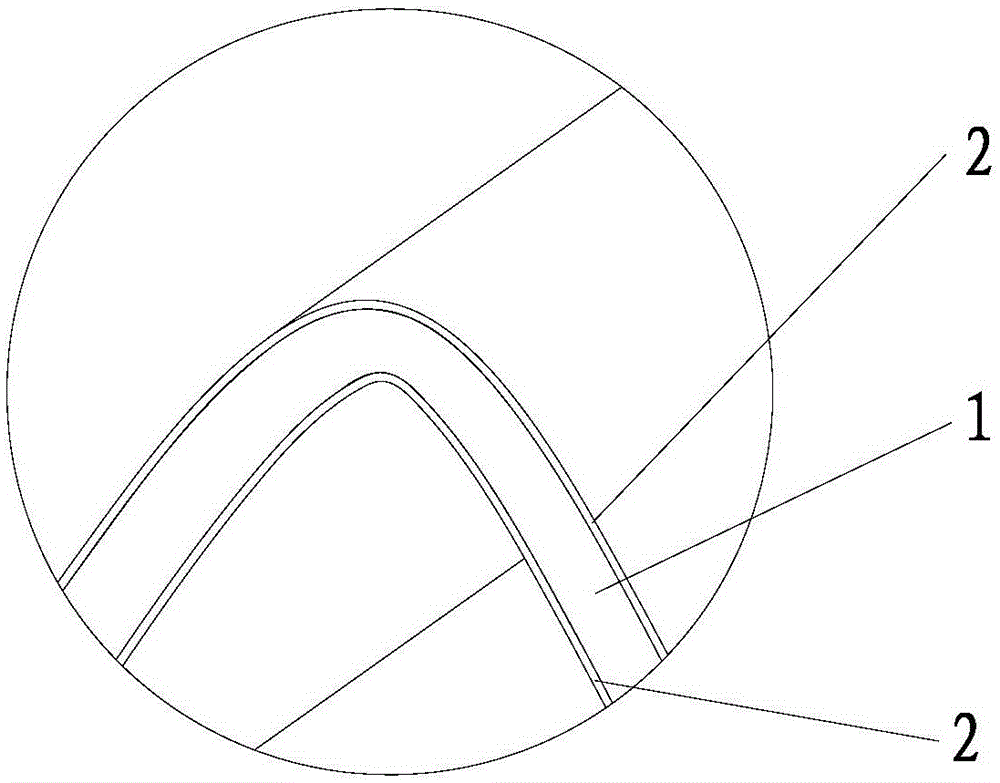

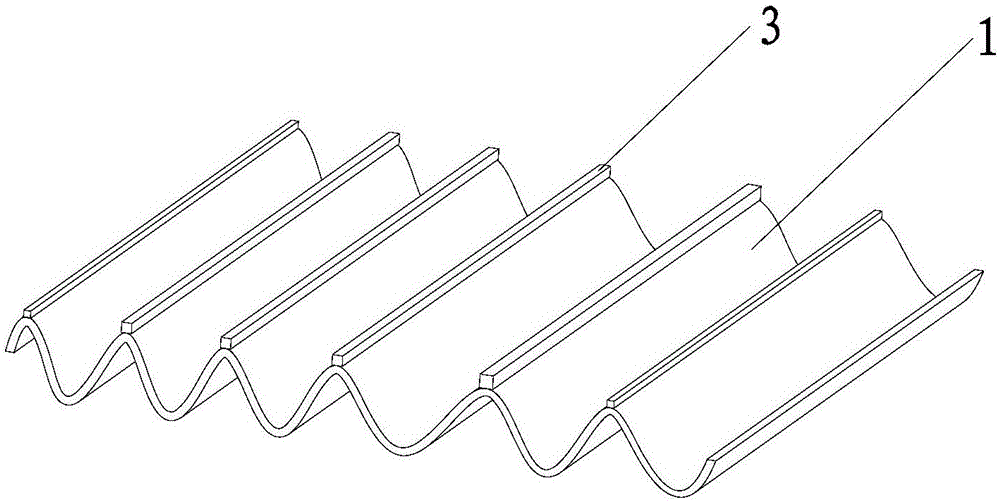

[0028] The manufacturing method of the corrugated plate provided in this embodiment, the structure of the corrugated plate produced according to this method is as follows: figure 1 and figure 2 As shown, it includes a corrugated substrate 1 as an intermediate layer and two layers of covering films 2 sandwiching the corrugated substrate 1 . The manufacturing method of this embodiment includes the following steps:

[0029] S1: Prefabrication of the substrate, select a solid wood board of a predetermined size and process a wavy substrate with uniform thickness on a precision milling machine or a machining center. The specific size of the solid wood board can be selected according to actual needs.

[0030] Considering the high cost of solid wood boards, square wooden strips of predetermined size can also be selected. The size of the square woode...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap