Steel-concrete composite structure continuous box girder and manufacturing method thereof

A combined structure and concrete technology, applied in bridges, bridge construction, bridge parts, etc., can solve problems such as limited precompression stress, affecting the crack resistance of concrete roofs, increasing the shear stress at the junction of concrete and steel beams, etc., to reduce The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

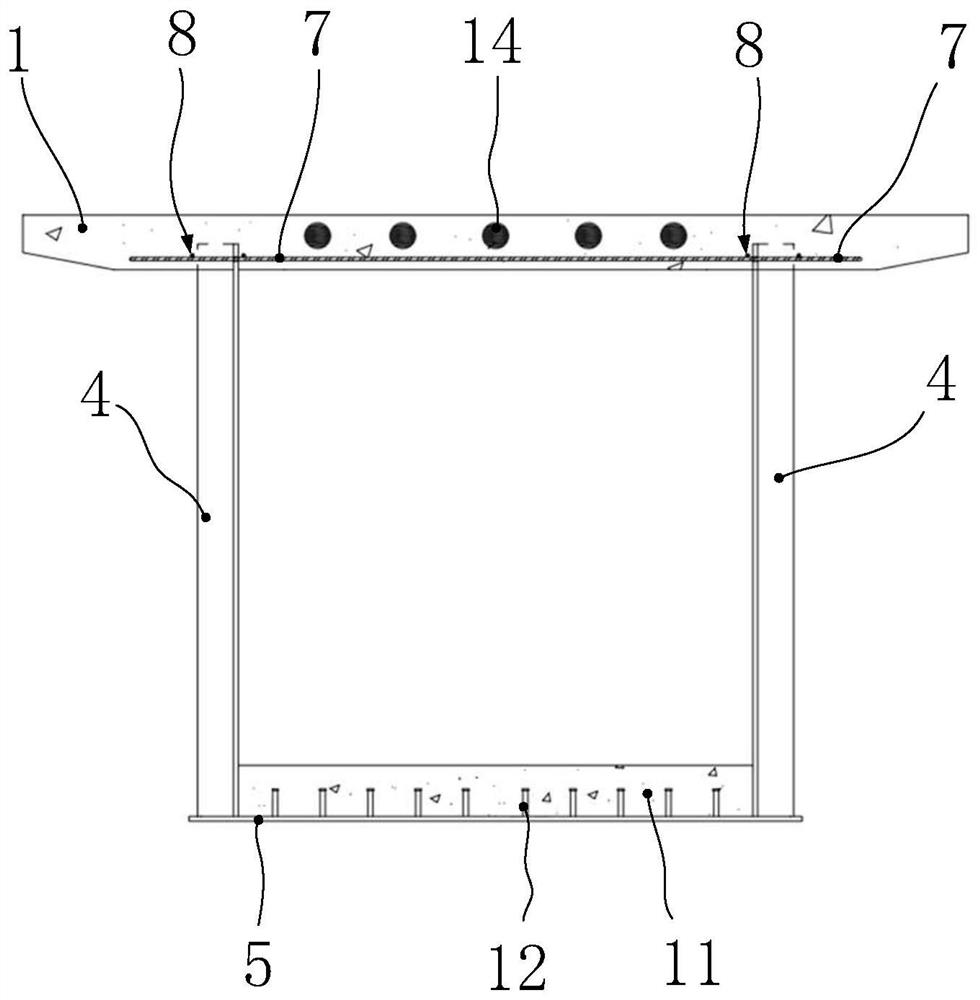

[0032] In order to facilitate the understanding of the present invention, the present invention will be described more fully below with reference to the associated drawings.

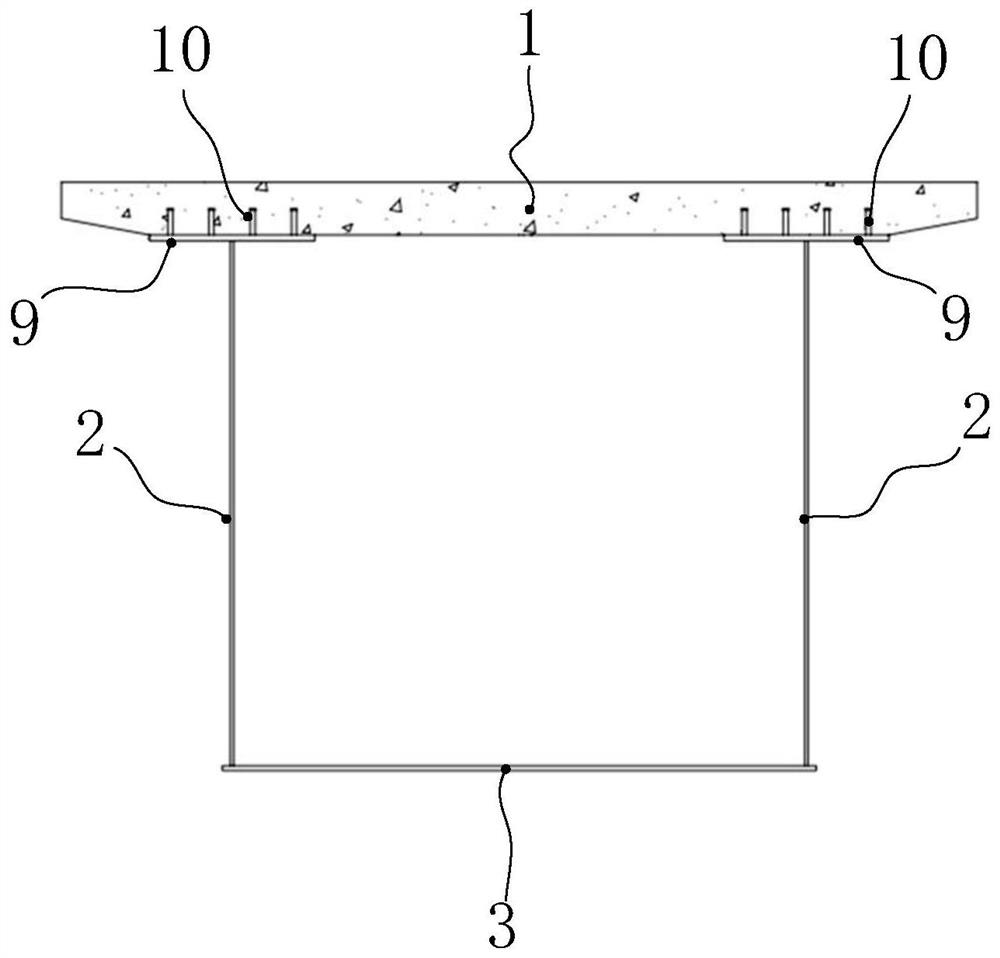

[0033] Such as Figure 1-7 As shown, a continuous box girder with steel-concrete composite structure includes a concrete roof 1, a steel box in the positive moment zone located in the mid-span region of the continuous beam, a steel box in the negative moment zone spanning the middle fulcrum of the continuous beam, and a steel box Connection plate 13. The steel box in the negative bending moment area is set in the negative bending moment area of the middle fulcrum, and the steel box in the positive bending moment area is connected to both ends of the steel box in the negative bending moment area.

[0034] Specifically, see figure 2 , the steel box in the positive bending moment area includes two flat steel webs 2 arranged in parallel, the first bottom plate 3 welded on the bottom of the two flat stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com