Fluidization system of powder material transport vehicle and powder material transport vehicle

A technology of fluidization system and transportation vehicle, which is applied in the field of fluidization system and powder material transportation vehicle, and can solve the problems of increasing steel usage and welding workload, cracking of sliding plate steel or welding seam, and reducing the effective volume of the tank, etc. Achieve the effects of reducing welding workload, increasing tank volume, and reducing steel usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

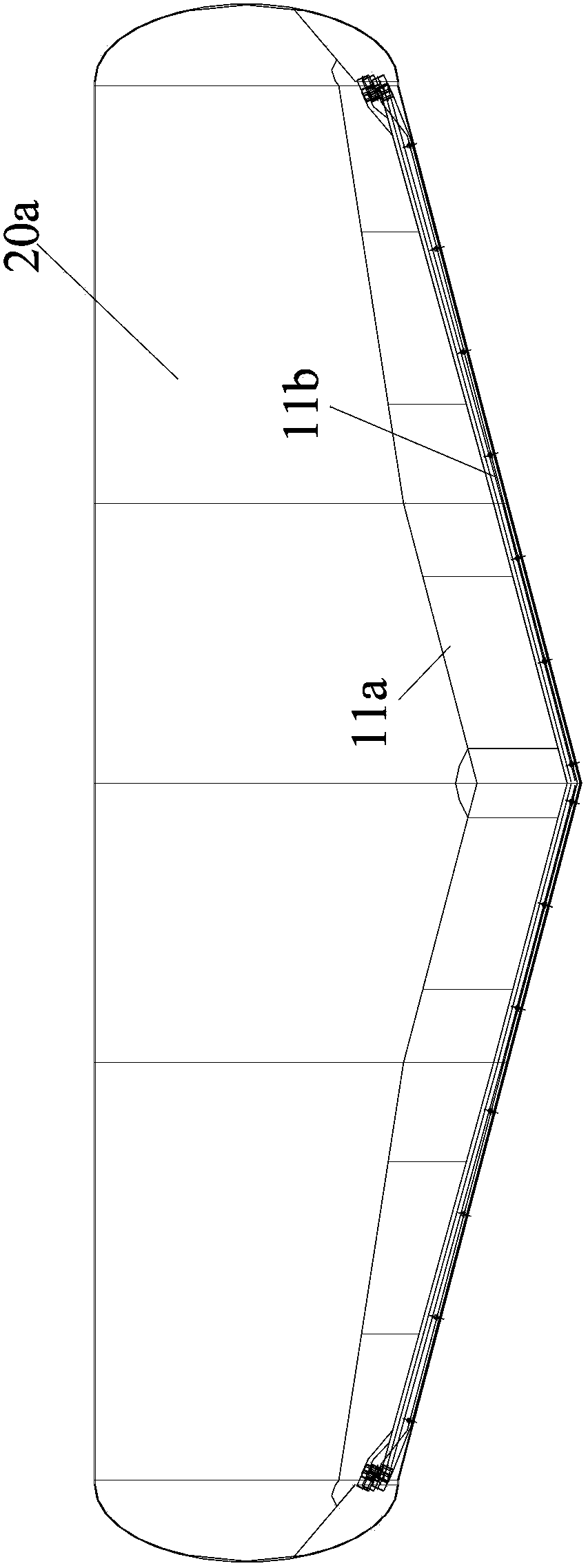

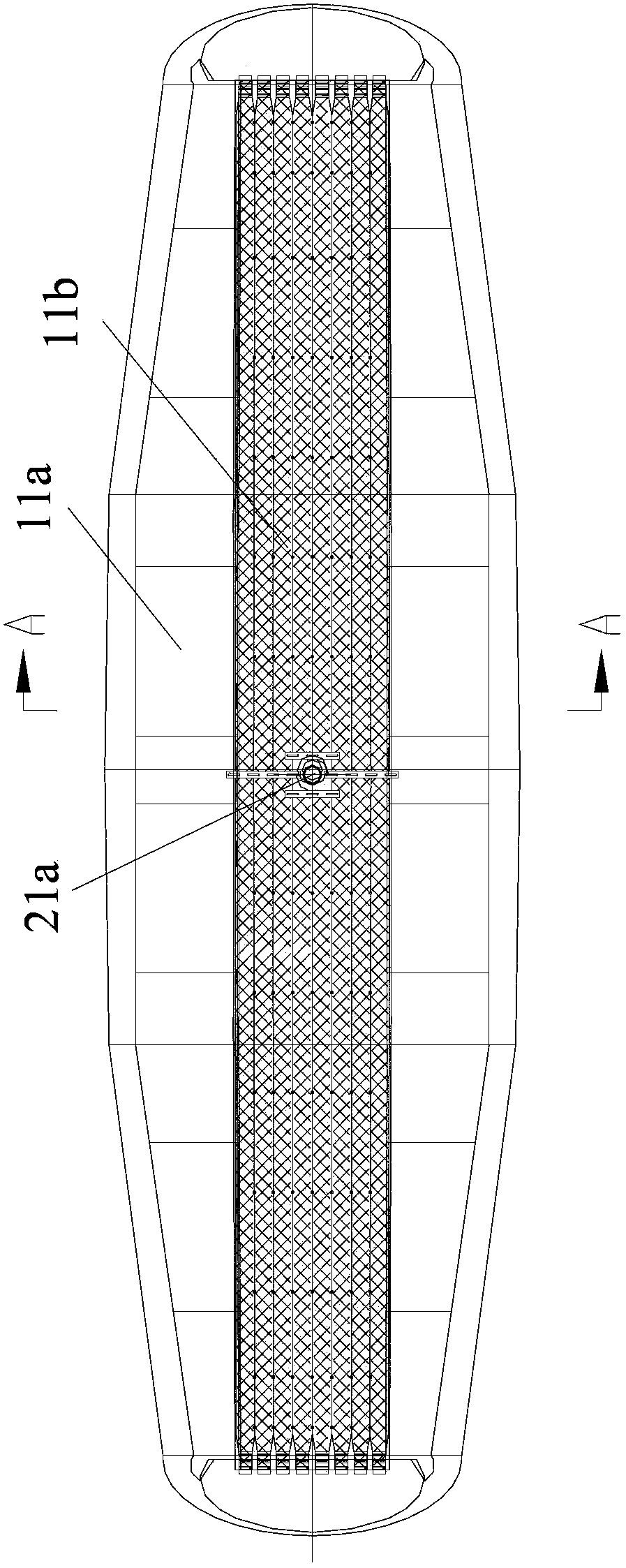

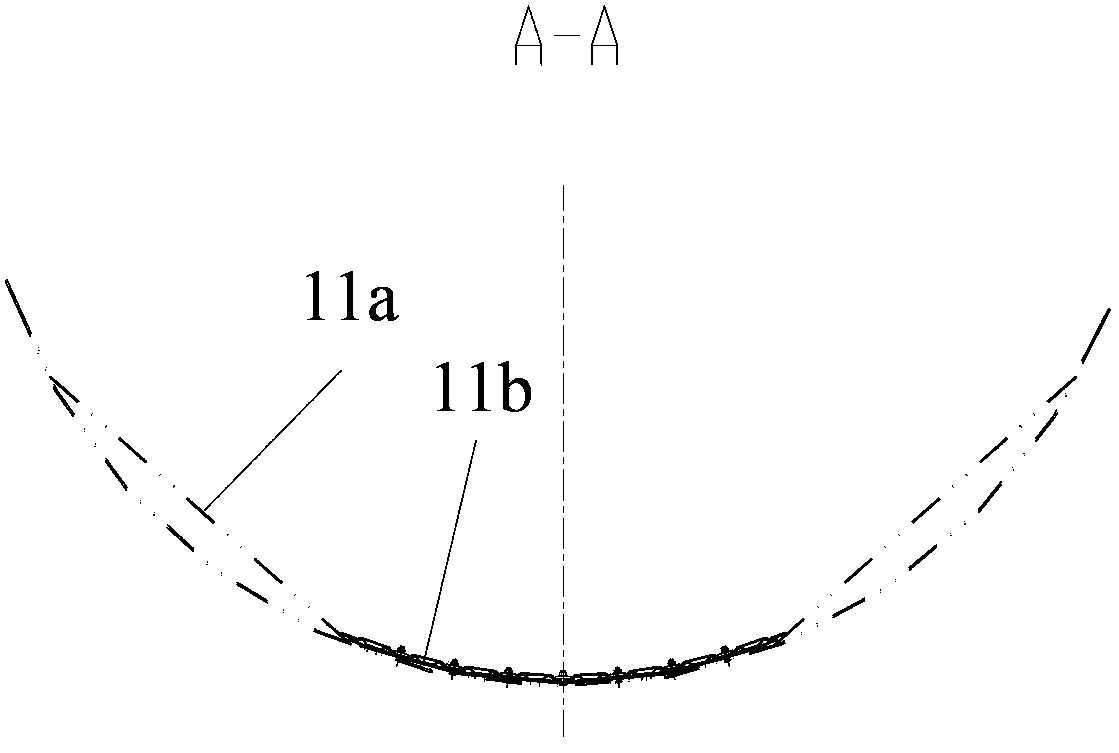

[0024] image 3 Shown is a schematic front view of the tank body and fluidization system of the powder material transport vehicle in an embodiment of the present invention. Figure 3A shown as image 3 A schematic top view of the tank and fluidization system of the transporter shown. Figure 3B shown along Figure 3A Schematic cross-section of line C-C in middle. Such as image 3 , Figure 3A and Figure 3B As shown, the powder material transportation vehicle includes a tank body 10 and a fluidization system 20 . The tank body 10 includes a body 12 and caps 11 disposed at two ends of the body 12 . The fluidization system 20 includes a plurality of air-permeable bags 21 located at the bottom of the tank body 10 , a plurality of pipe joints 22 respectively connected to each air-permeable bag 21 , and an end slide 23 arranged at the head 11 of the tank body 10 . The end slide plate 23 is arranged at the bottom of the head 11 and forms an air chamber 24 with the end head 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap