Die for producing poly(tetrafluoroethylene) plug cock and preparation method of plug cock

A polytetrafluoroethylene and mold technology, which is applied in the field of mold and the preparation of the cock, can solve the problems of cumbersome manufacturing process, waste, and difficulty in forming, and achieve the effects of increasing the output qualification rate, reducing production costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

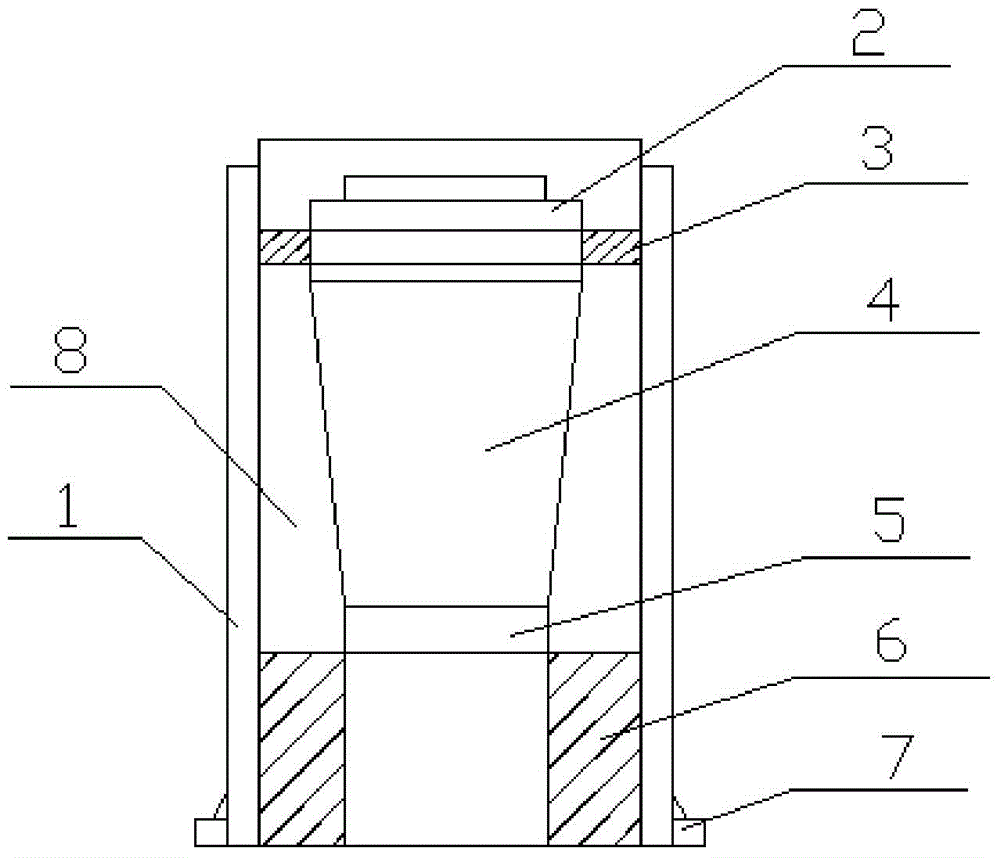

[0030] A kind of method utilizing above-mentioned mold to prepare polytetrafluoroethylene cock, raw material selects polytetrafluoroethylene suspension resin, comprises the following steps:

[0031] (1) Add the polytetrafluoroethylene suspension resin into the cavity 8, install the upper die 3, pressurize downwards, pre-press the polytetrafluoroethylene suspension resin, the pressure is 15MPA, and the pressure holding time is 5min;

[0032] (2) Two-way molding is used after holding the pressure, that is, the upper die 3 and the lower die 6 are pressurized at the same time, the pressure reaches 25MPA, and the holding time is 10min;

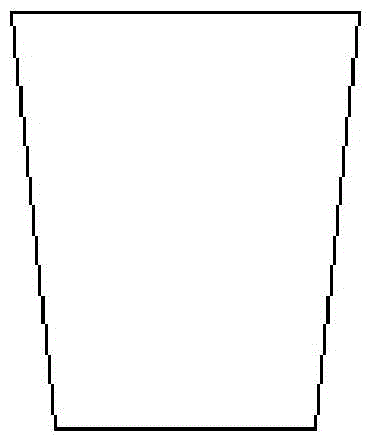

[0033] (3) Pressurize upwards on the lower die 6 again, the pressure is 15MPA, and the pressure holding time is 5min, after the pressure holding finishes, the mold is ejected, and the tapered tubular blank is made;

[0034] (4) Put the conical tubular blank on the outside of the plastic pile with the same shape and size as the central core 4, put i...

Embodiment 2

[0037] A kind of method utilizing above-mentioned mold to prepare polytetrafluoroethylene cock, raw material selects polytetrafluoroethylene suspension resin, comprises the following steps:

[0038] (1) Add the polytetrafluoroethylene suspension resin into the cavity 8, install the upper die 3, pressurize downwards, pre-press the polytetrafluoroethylene suspension resin, the pressure is 20MPA, and the holding time is 5min;

[0039] (2) Two-way molding is used after holding the pressure, that is, the upper die 3 and the lower die 6 are pressurized at the same time, the pressure reaches 35MPA, and the holding time is 10min;

[0040] (3) Pressurize upwards on the lower die 6 again, the pressure is 20MPA, and the pressure holding time is 5min, after the pressure holding is finished, the mold is ejected, and the tapered tubular blank is made;

[0041] (4) Put the conical tubular blank on the plastic pile with the same shape and size as the central core 4, and put it into the sinter...

Embodiment 3

[0044] A kind of method utilizing above-mentioned mold to prepare polytetrafluoroethylene cock, raw material selects polytetrafluoroethylene suspension resin, comprises the following steps:

[0045] (1) Add the polytetrafluoroethylene suspension resin into the cavity 8, install the upper die 3, pressurize downward, and pre-press the polytetrafluoroethylene suspension resin, the pressure is 1MPA, and the holding time is 15min;

[0046] (2) Two-way molding is used after the pressure holding, that is, the upper die 3 and the lower die 6 are simultaneously pressurized, the pressure reaches 40MPA, and the holding time is 1min;

[0047] (3) Pressurize upwards on the lower die 6 again, the pressure is 1MPA, and the pressure holding time is 15min, after the pressure holding finishes, the mold is ejected to make a tapered tubular blank;

[0048] (4) Put the conical tubular blank on the plastic pile with the same shape and size as the central core 4, and put it into the sintering furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com