Double-axle steering mechanism of electric bus

A technology of electric bus and steering mechanism, applied in the direction of power steering mechanism, steering mechanism, steering rod, etc., can solve the problems of heavy tire load, inconvenient seating and getting up of passengers, etc., to achieve less impact, easy to sit and get up, convenient and reasonable The effect of layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

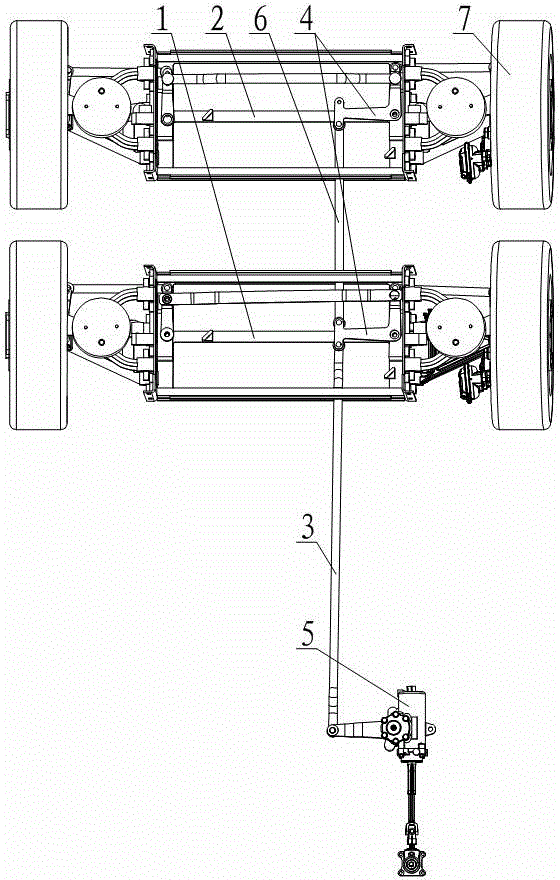

[0013] Such as figure 1 As shown, the double-bridge steering mechanism of an electric bus includes a first steering axle 1, a second steering axle 2, a longitudinal tie rod 3, a steering booster 5, and an intermediate tie rod 6, wherein the first steering axle 1 and the second steering axle 2 are arranged horizontally and parallel to each other, and both the first steering bridge 1 and the second steering bridge 2 are connected with a steering rocker arm 4. The longitudinal tie rod 3 and the intermediate tie rod 6 are arranged longitudinally and coaxially. The two ends of the longitudinal tie rod 3 are respectively connected to the steering booster 5 and the steering rocker arm 4 on the first steering axle 1, and the two ends of the intermediate tie rod 6 are respectively connected to the first steering axle The steering rocker arm 4 on 1 and the steering rocker arm 4 on the second steering axle 2. In this embodiment, a steering wheel 7 connected to the first steering bridge 1...

Embodiment 2

[0016] This embodiment further defines the following on the basis of embodiment 1: The steering rocker arm 4 of this embodiment includes a horizontal connecting plate and a longitudinal connecting plate, wherein the front end of the longitudinal connecting plate and the transverse connecting plate After connecting, the longitudinal connecting plate and the horizontal connecting plate form an "L" shape as a whole. In order to provide the structural strength of the steering rocker arm 4, in this embodiment, the horizontal connecting plate and the longitudinal connecting plate of the steering rocker arm 4 are integrated into one body. In this embodiment, the steering rocker arm 4 on the first steering bridge 1 is set on the first steering bridge 1 by a limit pin that passes through the connecting part of the transverse connecting plate and the longitudinal connecting plate, and the steering rocker arm on the second steering bridge 2 is 4 is set on the second steering bridge 2 by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com