Spiral type vertical conveying device

A conveying device and screw-type technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of low work efficiency, poor continuous operation ability, and consistent production line rhythm, so as to save the space occupied by equipment, Improve work efficiency and facilitate the effect of reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

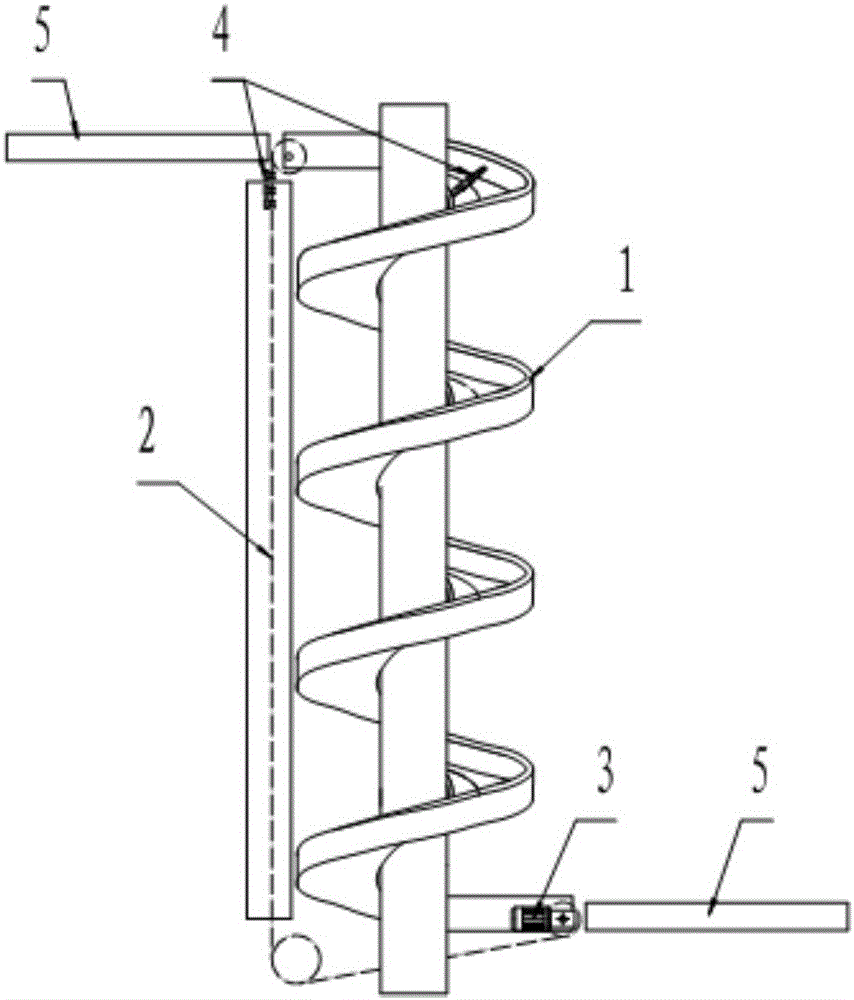

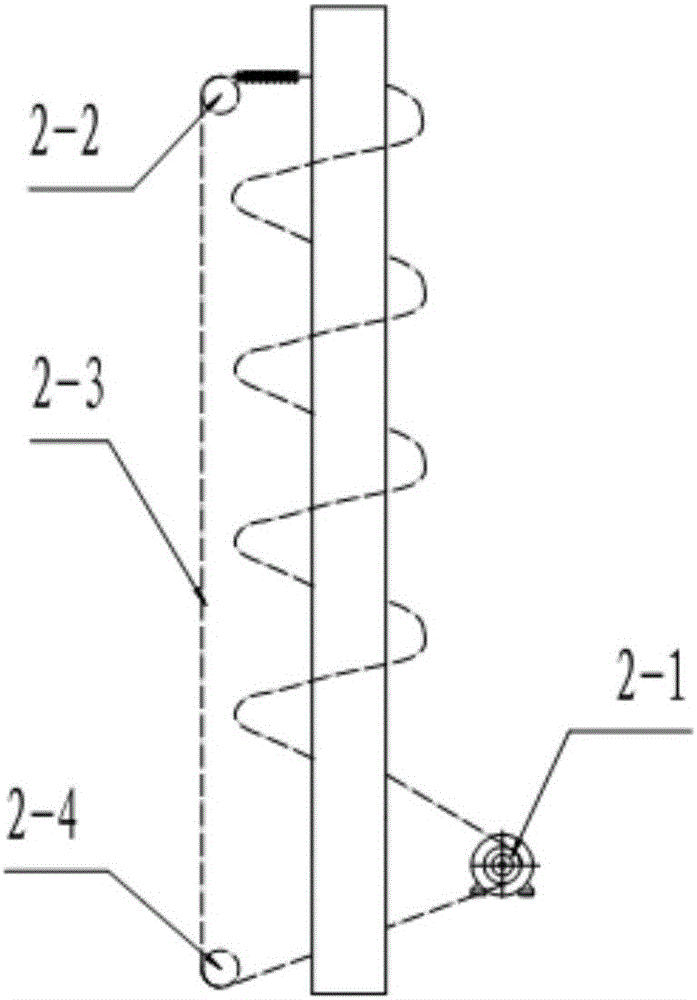

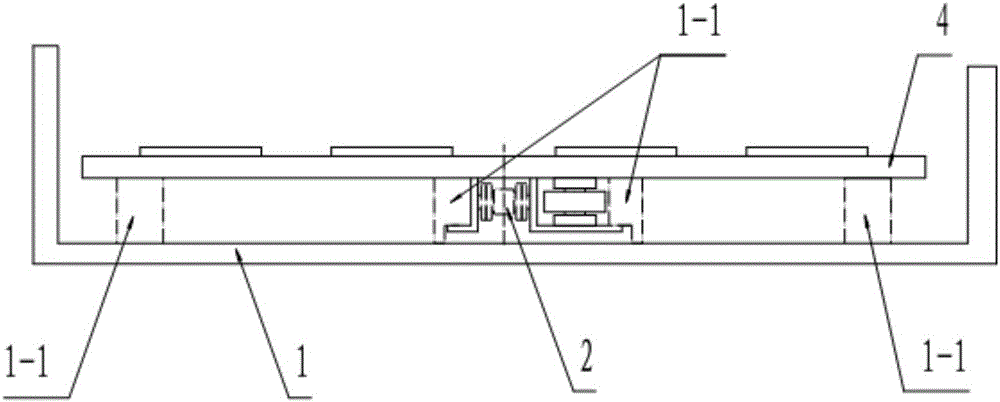

[0021] see figure 1 , figure 2 , image 3 , the present invention is a spiral vertical conveying device, comprising a spiral track 1, a blade conveyor belt 4, a drive mechanism 3 and a chain drive mechanism 2; A group of guide rails 1-1 are arranged along the direction of the centerline on the spiral track 1; the driving mechanism 3 is fixed on the upper or lower end of the spiral track 1, and the driving mechanism 3 adopts a geared motor assembly for driving the chain transmission mechanism 2 Running; the blade conveyor belt 4 is installed on the chain drive mechanism 2 .

[0022] see image 3 , Figure 4 , Figure 5 , in the spiral vertical conveying device according to the present invention, the blade conveyor belt 4 is composed of a group of blades 4-1 whose number matches the length of the chain transmission mechanism 2, and the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com