Shipborne stirring station

A mixing station and ship-mounted technology, which is applied in the field of concrete production equipment, can solve the problems that concrete mixing equipment is not suitable for mobile feeding, the degree of automation of ship-borne mixing stations is low, and the safety and reliability cannot be guaranteed. Solve the problem of deviation, high degree of automation, and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

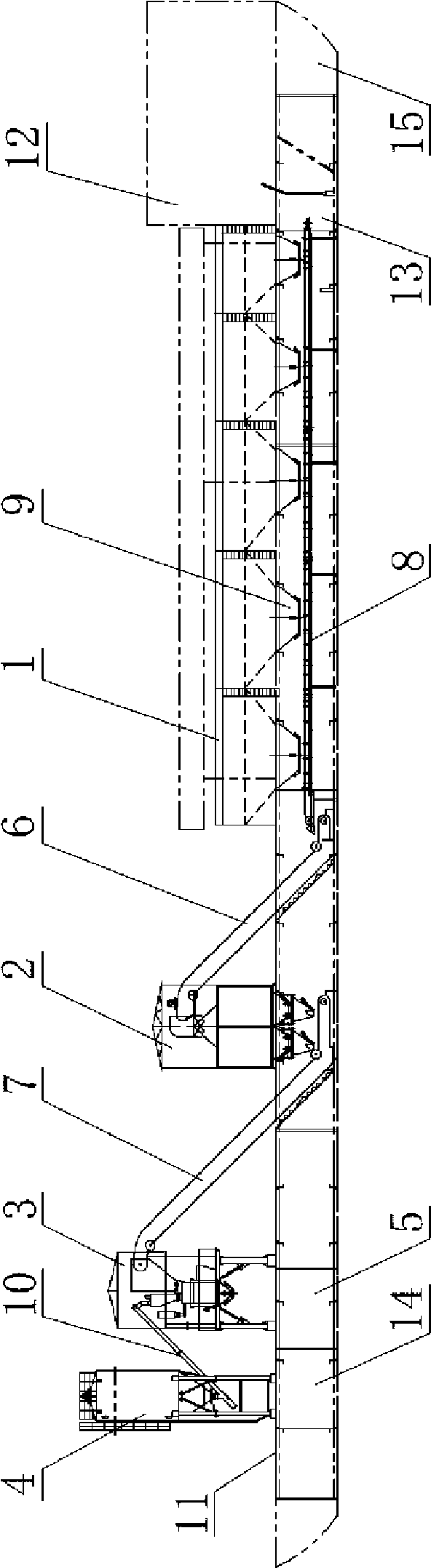

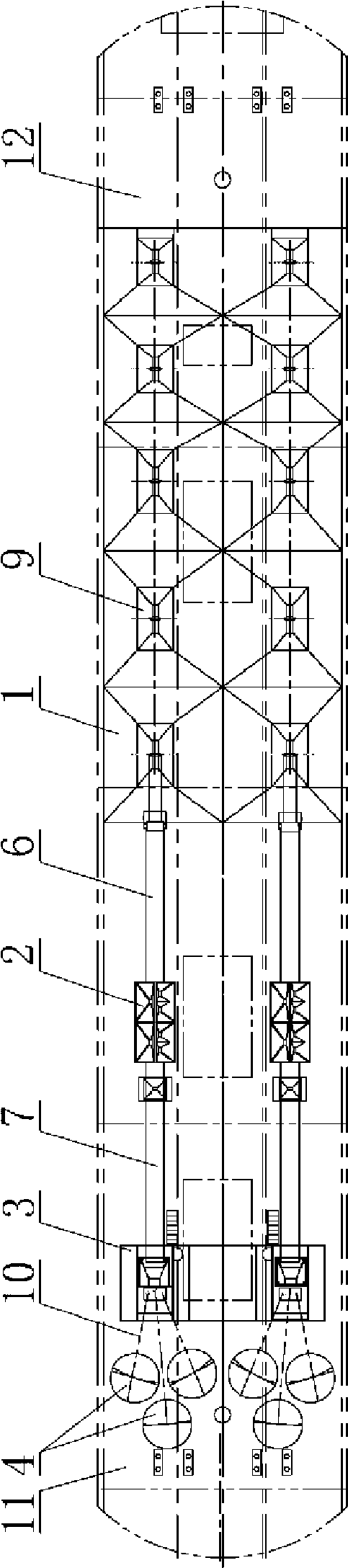

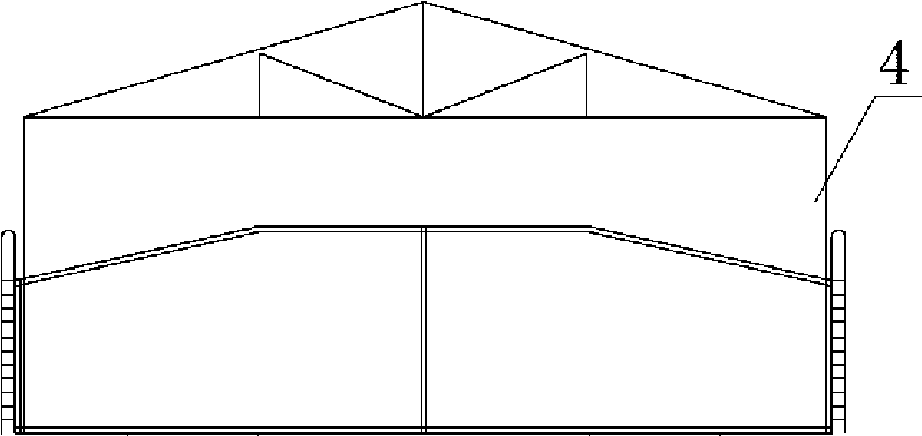

[0033] Examples see figure 1 , figure 2 As shown, this kind of ship-mounted mixing plant includes a hull 11 with a comprehensive chamber 12 and a mixing station located on the hull 11. There are two mixing plants on the hull 11, and the two mixing stations are in the longitudinal center of the hull. Axial symmetrical arrangement, each set of mixing station includes sand and gravel aggregate silo 1, batching building 2, mixing building 3 and powder silo 4 which are sequentially distributed along the longitudinal direction of the hull. Arranged longitudinally along the hull, each sand and gravel aggregate bin has a cylinder-controlled unloading hopper 9 in the middle. Below the unloading hopper, a horizontal conveying device 8 is fixed on the hull. The discharge end of the horizontal conveying device 8 and the primary lifting The feed end of the machine 6 is matched and connected, the discharge end of the primary hoist 6 is located at the inlet of the batching building 2, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com