Silo center discharging machine driven by internal motors

A central unloading, motor-driven technology, applied in the direction of conveyor objects, loading/unloading, cleaning devices, etc., can solve problems such as high equipment costs, silo blockage, sticking, knotting, and unloading machine leakage. Achieve effective use of internal space, occupy less space, and reduce equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific drawings.

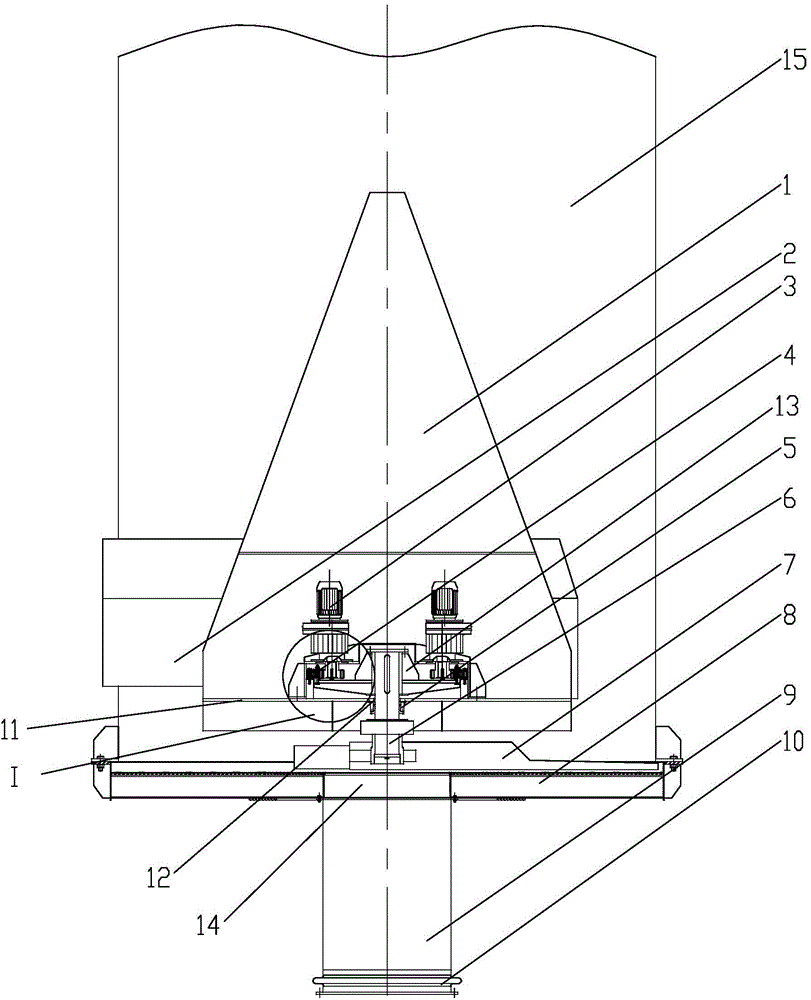

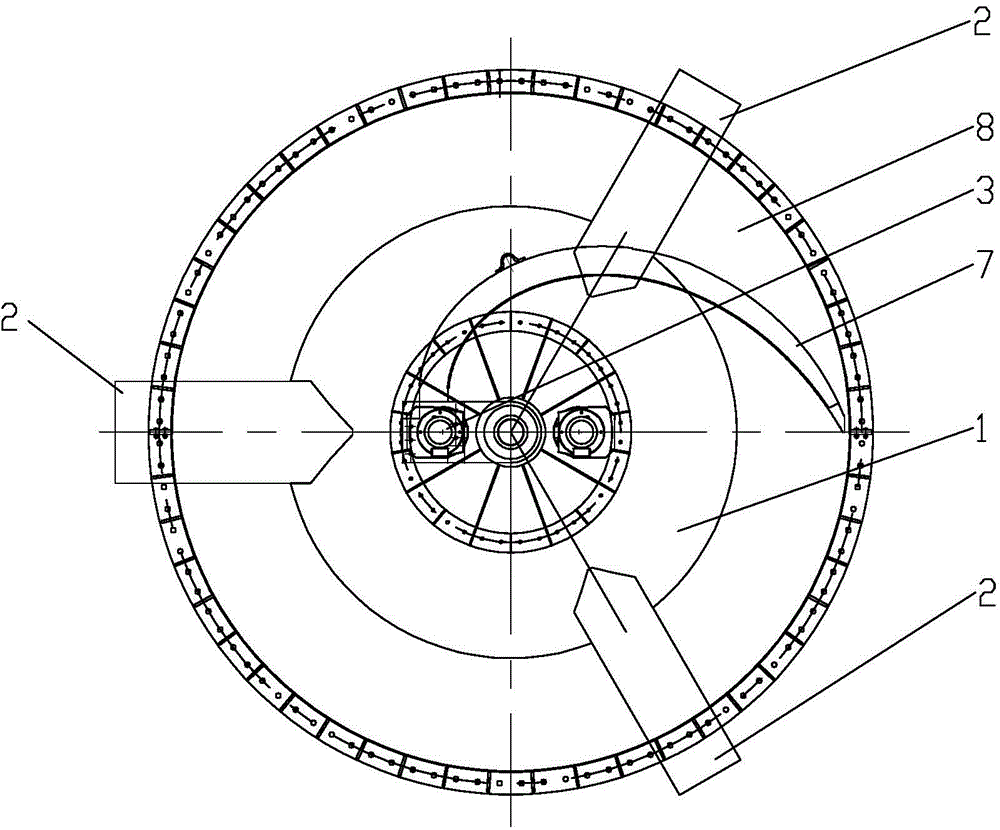

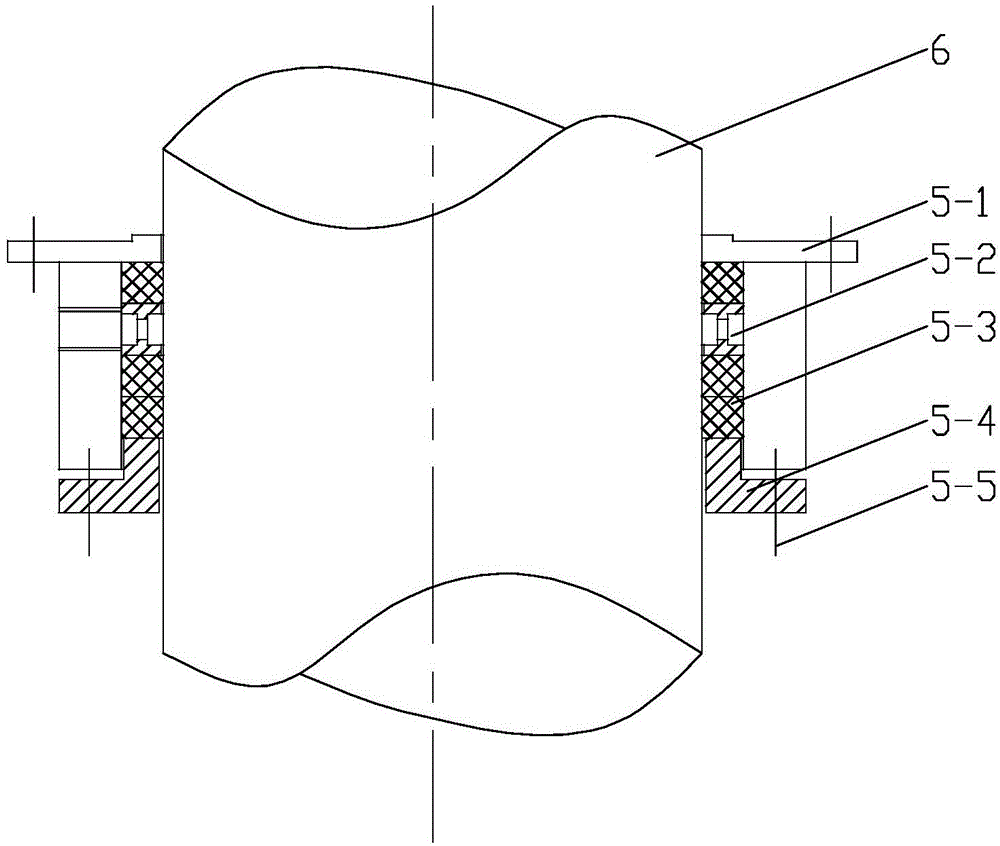

[0015] like Figure 1-Figure 4 As shown: the silo center unloader driven by an internal motor includes a decompression cone 1, a support beam 2, a drive motor 3, a slewing support 4, a shaft seal device 5, a seal seat 5-1, an air ring 5-2, Forming filler 5-3, gland 5-4, compression bolt 5-5, main shaft 6, discharge arm 7, chassis 8, drop pipe 9, compensator 10, bottom plate 11, through hole 12, bushing 13, Outlet 14, silo 15, etc.

[0016] like figure 1 , figure 2 As shown, the present invention includes a decompression cone 1 arranged inside the silo 15. The decompression cone 1 is erected at the bottom center of the silo 15 through a support beam 2. The decompression cone 1 is a hollow structure, and the cone top of the decompression cone 1 Upward, the bottom of the cone is provided with a bottom plate 11, the bottom plate 11 inside the decompression cone 1 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com