A kind of coking process method

A process method and coke oven technology, which are applied in the field of coking process, can solve the problems of untight sealing walls of regenerators and ramps, small coke output, and low coke shrinkage rate, and achieve easy coke pushing and coke output. Great, improve the effect of tar quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

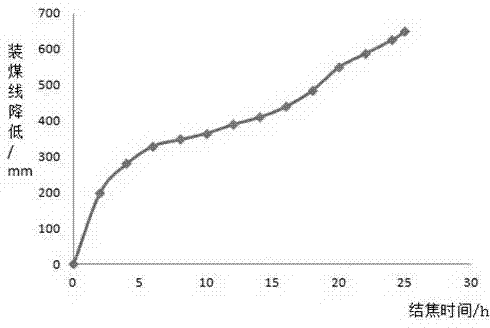

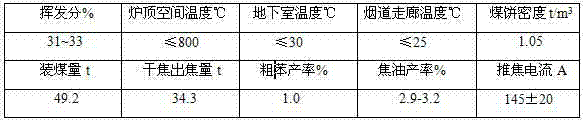

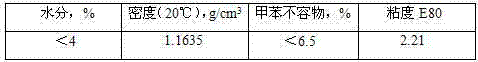

[0034] In the coking process, the total length of the carbonization chamber is 15980mm, and the effective length is 15100mm. The average width of the carbonization chamber is 620mm, the overall height is 5505mm, and the effective height is 5200mm. Taper 70mm. The center distance of the carbonization chamber is 1420mm, and the effective volume of the carbonization chamber is 44.7 cubic meters. The sealing wall of the regenerator and the furnace head of the chute are made of light clay insulation bricks, insulation coatings, calcium silicate slabs and insulation coatings on four layers from the inside to the outside. The main film-forming substance of thermal insulation coating is sepiolite, and the filler is expanded perlite. The heating level is 1100mm. The number of fire channels in each combustion chamber is 32. The center distance of the combustion chamber is 480mm, and the design coking time is 26h. The coke oven column is made of H-shaped steel. Bead bricks are laid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com