Disc type steel ball temperature control isothermal quenching device

A isothermal quenching, disc-type technology, applied in quenching device, heat treatment process control, heat treatment equipment, etc., can solve the problems of different temperature of steel balls, clustering, and mixing, etc., and achieve the effect of improving quenching quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

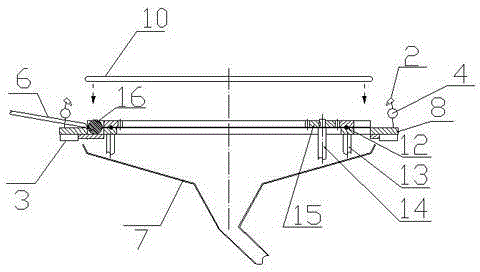

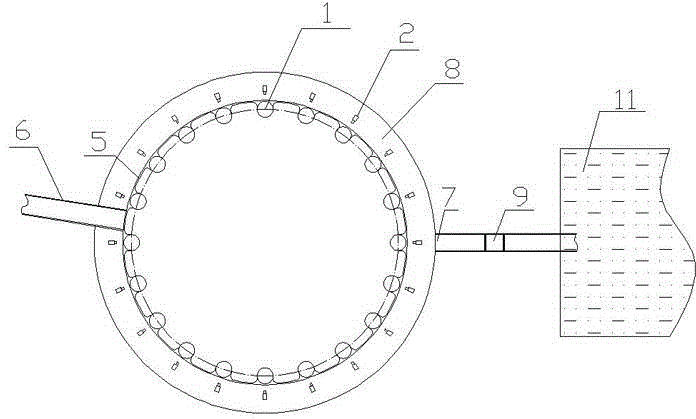

[0016] As shown in the figure, the disc-type steel ball temperature-controlled isothermal quenching device consists of an annular chassis 8, a turntable 5, a steel ball conveyor 6, a pallet-type steel ball track 7, an infrared temperature probe 2, an intelligent temperature control switch 4, and a telescopic device 3 and the quenching pool 11, the annular chassis 8 is fixed on the foundation by the bracket 13, the annular chassis 8 is evenly provided with a number of ball drop holes 1 in the circumferential direction, the turntable 5 is an internal gear, and the turntable 5 is driven to rotate by the gear 15, and the turntable 5 A number of circular arc grooves are uniformly arranged on the outer peripheral surface of the circular arc groove in the upper direction, the radius of curvature of the circular arc groove is the same as the radius of the ball drop hole 1, and the center line of the arc groove and the center line of the ball drop hole 1 are on the same cylindrical surfa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap