Connecting structure of heavy-load GRC curtain wall system and all-steel main structure

A technology of main structure and connection structure, applied in the direction of building structure, construction, etc., can solve the problems of large force load at the connection point, difficult construction, complex connection between the curtain wall and the main structure, etc., to improve the firmness and construction. Efficiency, ensuring the effect of a single chip area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0028] Example

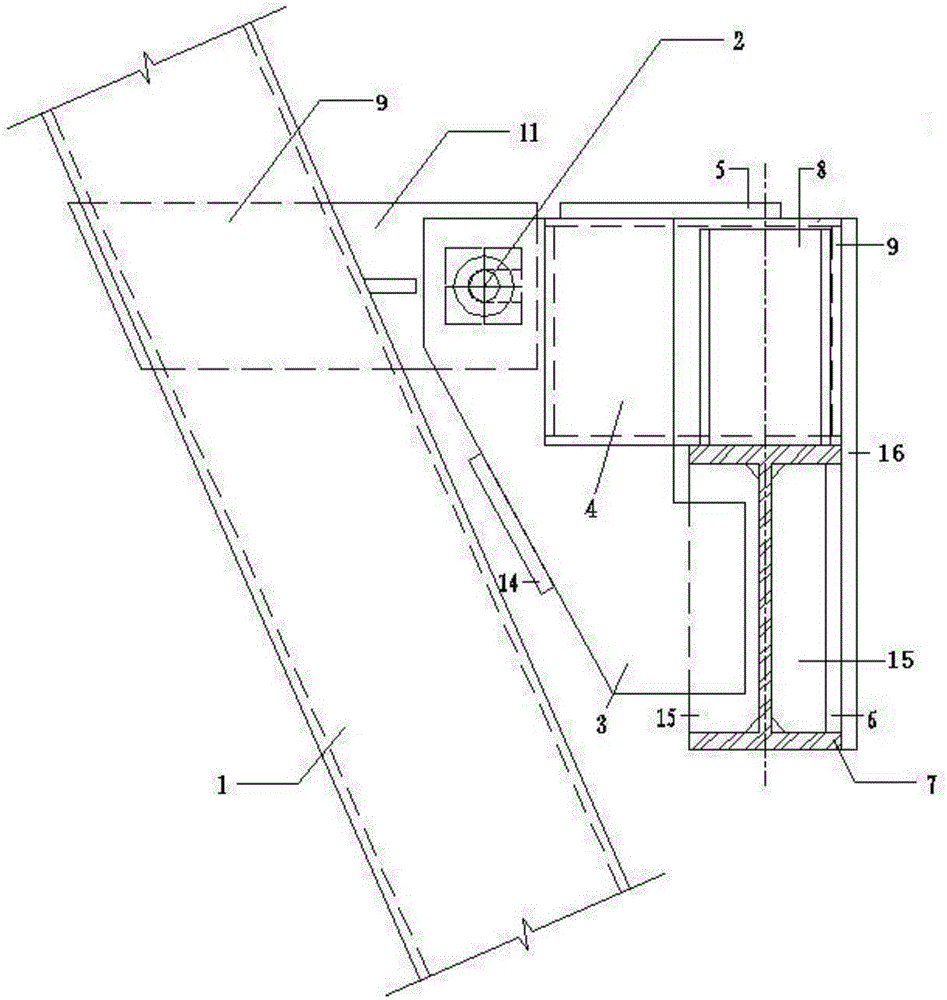

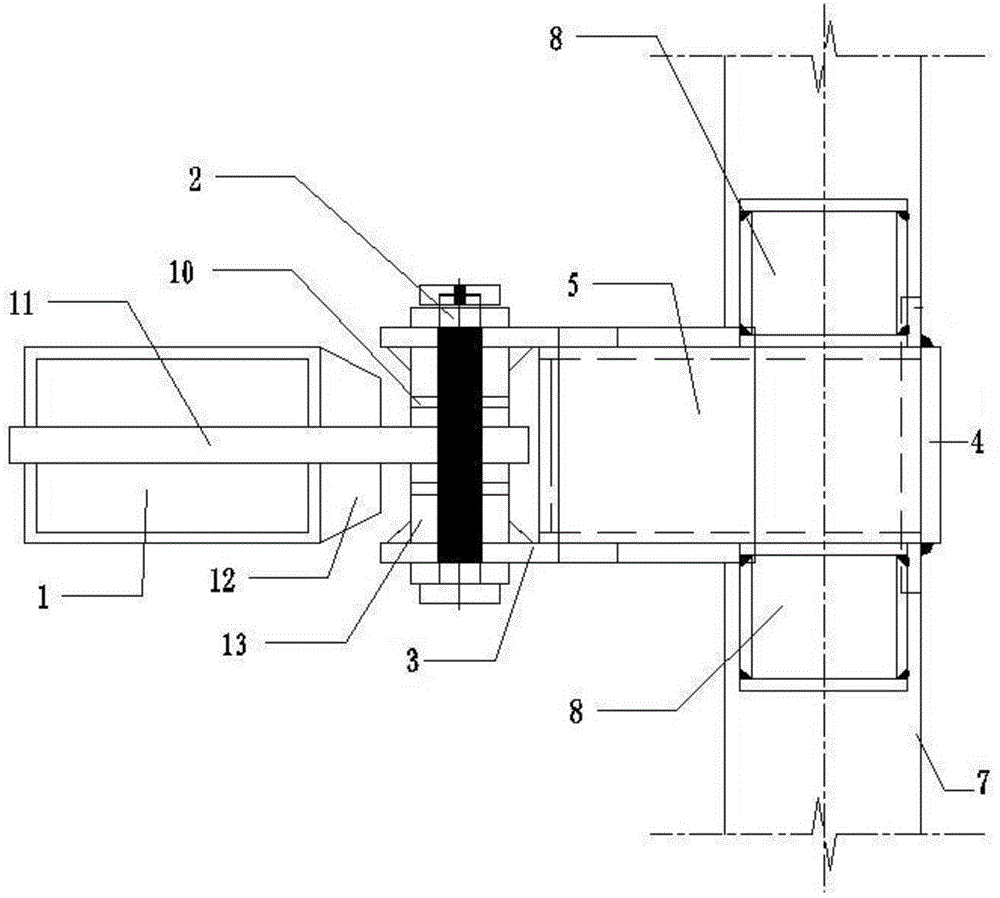

[0029] The connection structure between the heavy-load GRC curtain wall system and the all-steel main structure in this embodiment is suitable for the reliable connection between the heavy-load GRC curtain wall and the all-steel main structure, where the cantilever length of the connecting corbel is less than or equal to 400mm. The connection method of buried steel connection corbel + pin shaft ensures the connection reliability of the GRC curtain wall structure with large single-piece area and heavy load and the all-steel main structure.

[0030] The connection structure between the heavy-load GRC curtain wall system and the all-steel main structure in this embodiment includes steel beams 7 of the all-steel main structure, secondary steel members 1, connecting corbels 4, two return-type connectors 8, two pieces of corbels Leg side connecting support plate 3, connecting ear plate 11, pin shaft 2, second stiffening plate 12, third stiffening plate 14, steel bea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap