Tea leaf baker

A technology of roasting machine and tea leaves, which is applied in the direction of tea processing before extraction, can solve the problems of low utilization rate of heat energy and high energy consumption, and achieve the effects of uniform heat, reduced transfer and uniform heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The following describes the embodiments of the present invention in further detail with reference to the accompanying drawings:

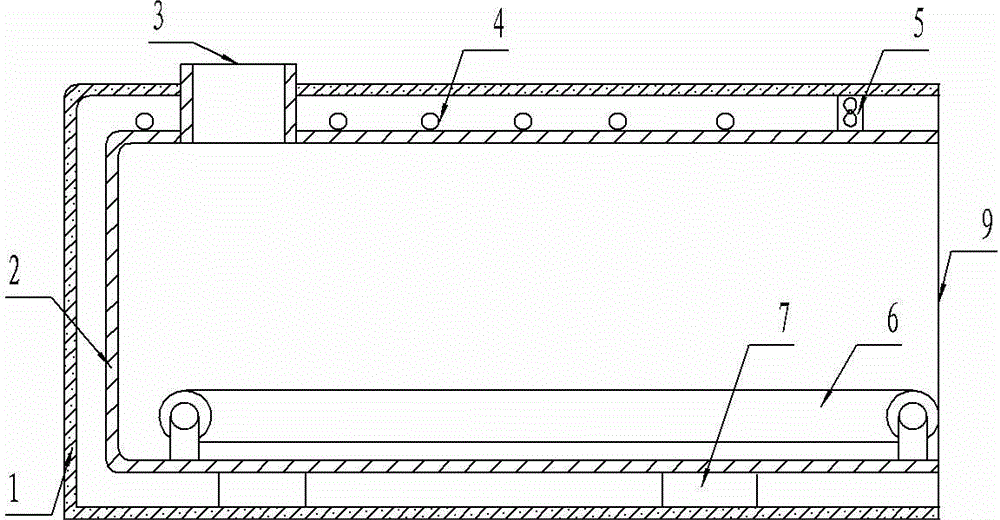

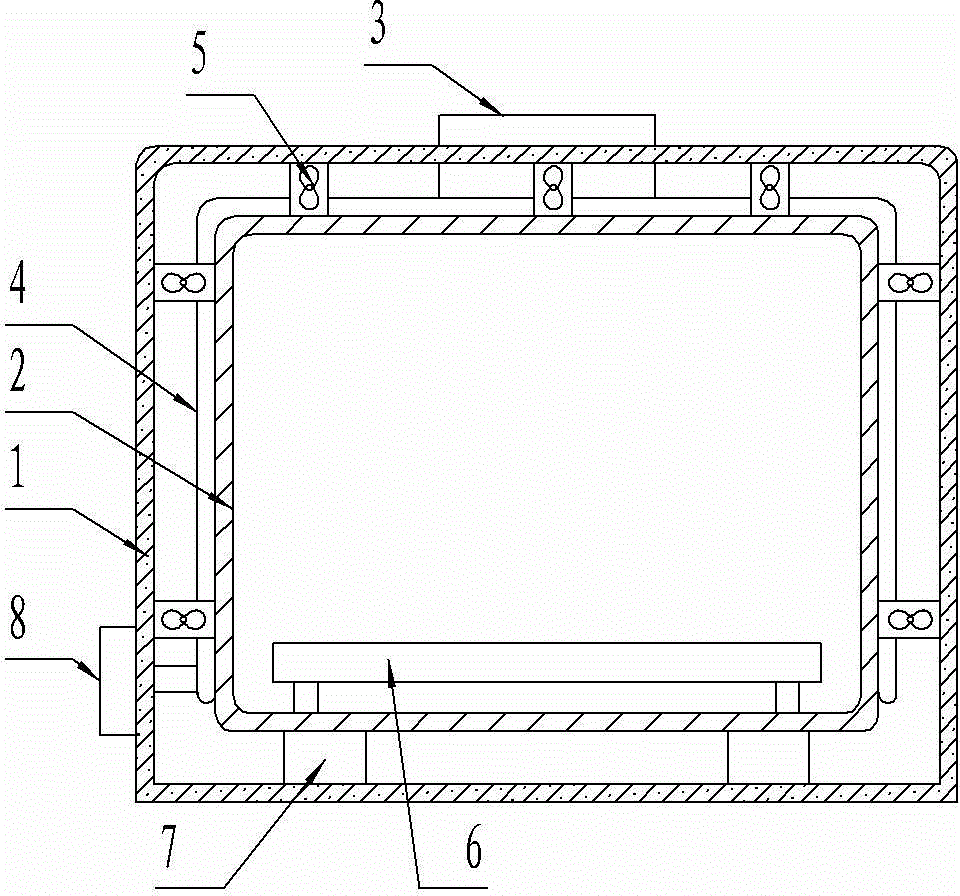

[0010] Such as figure 1 , figure 2 The tea roasting machine shown includes a box with an inlet 3 and an outlet 9. An electric heater is arranged in the box, and a conveyor belt 6 for placing tea is also arranged in the box. The inlet 3 is opened at On the top of the box body, the discharge port 9 is opened on one side of the box body, so that the heat energy is not easily taken away by the wind express of the conveyor belt. The box body is provided with an inner wall 2 and an outer wall 1. The electric heater is an electric heating tube 4. The electric heating tube 4 is evenly arranged between the inner wall 2 and the outer wall 1. The part of the electric heating tube 4 where the electrode extends out of the outer wall 1 is provided with a power switch . The box is designed as a hollow structure, which greatly reduces the transfer of heat en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com