Building block type dummy body structure of punching bag

A technology of building blocks and piles, which is applied in the field of building block pile structures, can solve the problems of unfavorable packaging, storage and transportation, redundant piles, high storage and transportation costs, and achieve the effect of saving transportation costs and facilitating storage and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

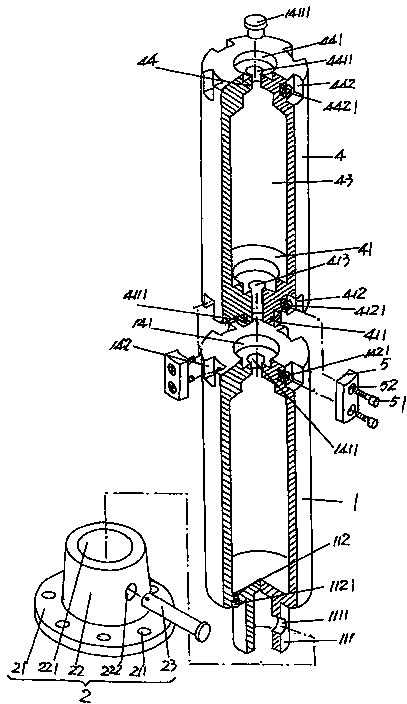

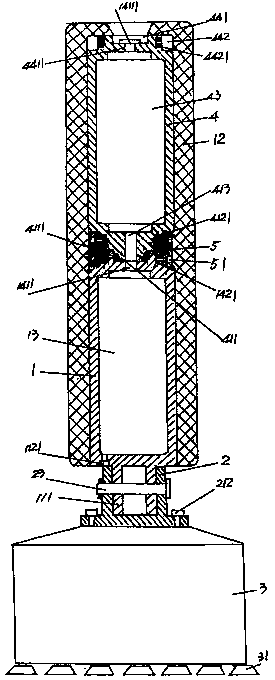

[0021] See figure 1 and figure 2 , shows a pile body 1 made of plastic, in the use state of the bottom wall 11 of the pile body 1, there extends toward the middle position of the lower side with a diameter smaller than the diameter of the pile body 1 and connected to the bottom The wall 11 forms a base joint 111 in a vertical relationship, and a striking layer 12 is integrated on the outer wall of the pile body 1 and around the periphery of the pile body 1 .

[0022] As the technical points of the technical solution of the present invention: the aforementioned pile body 1 forms a pile body cavity 13, on the top wall 14 of the pile body 1 and at the center of the side of the top wall 14 facing away from the pile body cavity 13 The position constitutes an additional pile body connection seat standby cavity 141 depressed on the surface of the top wall 14, and a central position at the bottom of the additional pile body connection seat standby cavity 141 is provided with a pile ...

Embodiment 2

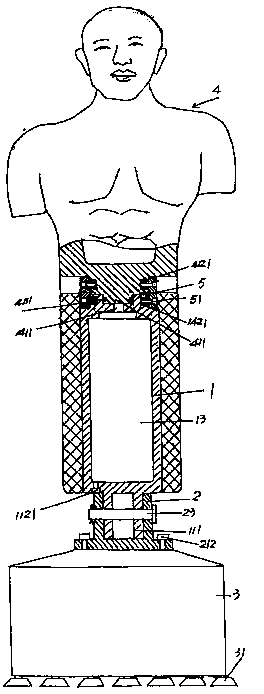

[0035] See image 3 , just change the shape of the first-level additional pile body 4 into the shape of the mannequin (other similar shapes can also be arranged), and all the other are the same as the description of embodiment 1.

Embodiment 3

[0037] See Figure 4 Add a second-level additional pile body 6 that is identical in structure to the first-level additional pile body 4 on the top of the first-level additional pile body 4, and change the base 3 into a plate-shaped structure, and the pile body 1, The height of the first-level additional pile 4 and the height of the second-level additional pile 6 is selected as 0.5m, and the connection between the second-level additional pile 6 and the first-level additional pile 4 is the same as the connection between the first-level additional pile 4 and the pile body 1. Description of the connection, and the striking layer 12 extends to the outer wall of the secondary additional pile body 6, the opening and closing cover 4111 of the medium introduction hole is transferred to the top of the secondary additional pile body 5, and the rest of the content not mentioned is the same as that of embodiment 1 description of.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com