Sealing ring quick installation machine

A sealing ring and installation machine technology, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems of difficulty in returning to the original shape, low production efficiency of the sealing ring, and increased processing steps, so as to reduce the operation labor intensity and reduce the manufacturing cost. , reduce the effect of shaping operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

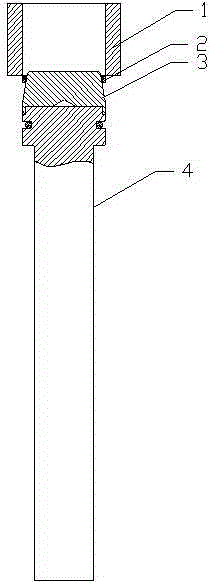

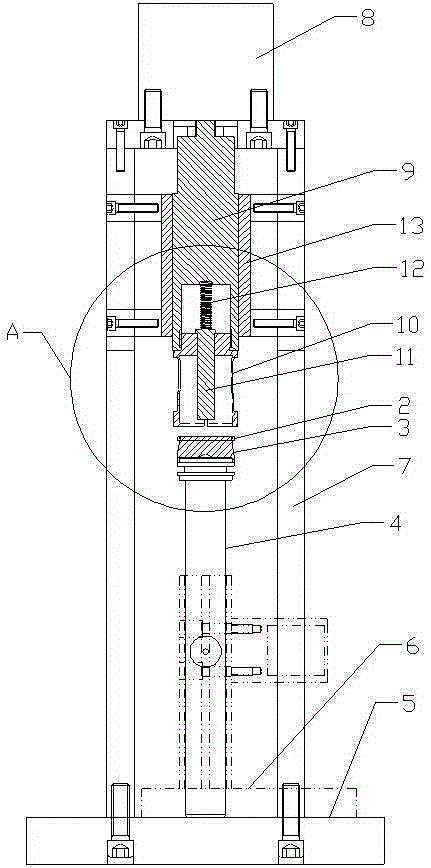

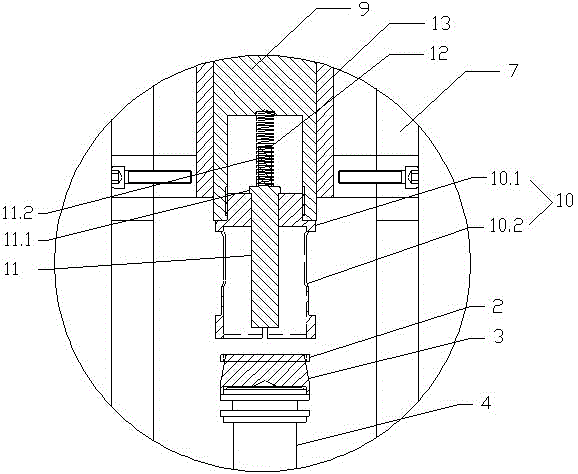

[0028] see figure 2 and image 3 , a sealing ring quick installation machine related to the present invention, which includes a machine platform 5, a part mounting seat 6 is arranged on the machine platform 5, the part 4 is vertically arranged on the part mounting seat 6, and the part mounting seat 6 includes a V-shaped block and quick change clips. The top of part 4 is provided with expansion ring 3, the outer edge size of expansion ring 3 gradually increases from top to bottom, sealing ring 2 is placed on expansion ring 3, the sealing groove of part 4 is located under expansion ring 3, and machine platform 5 is set There is a frame 7, the top of the frame 7 is provided with a downward cylinder 8, the telescopic end of the cylinder 8 is connected with a connecting shaft 9 downward, the lower end of the connecting shaft 9 is connected with a pressure sleeve 10, and the frame 7 is provided with an upper and lower direction guide sleeve 13, the connecting shaft 9 is located i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com