Operation method of an injection molding machine

An operation method and injection molding machine technology, applied in the field of injection molding machine equipment, can solve the problems of large damage, large vibration and noise, and long energy consumption of various parts of the injection molding machine, so as to reduce deformation time, reduce vibration and noise, and increase service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following embodiments are combined with the accompanying drawings to illustrate the present invention in detail. And define the direction from the fixed template to the movable template as the direction from front to back.

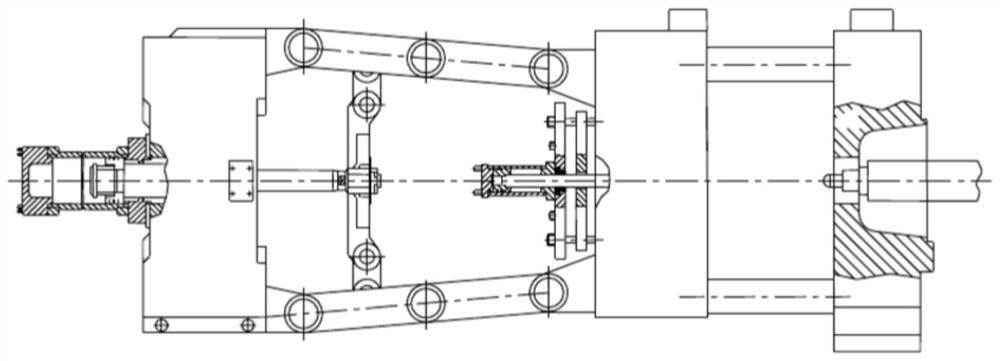

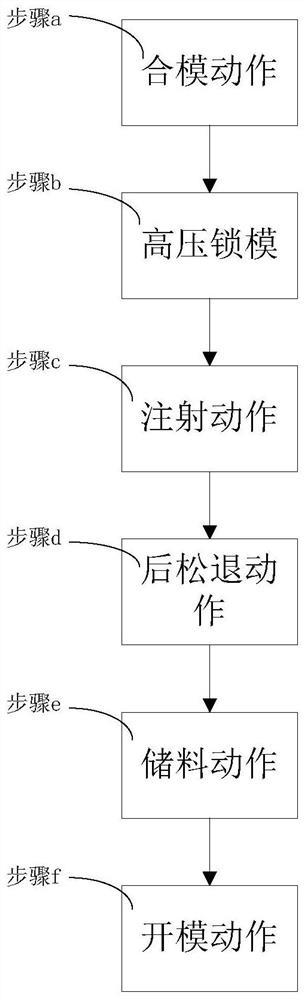

[0021] refer to figure 2 As shown in , in the operation method of the injection molding machine provided by the present invention, the injection molding machine includes a mold opening and closing cylinder, an injection assembly, a fixed platen, a movable platen, a rear platen, and a mold located between the fixed platen and the movable platen. There is a connecting cross thrust seat and connecting rod between the formwork and the rear formwork, and the piston end of the mold opening and closing cylinder passes through the back formwork to connect to the cross thrust seat, and the two ends of the connecting rod are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com