Fluid filter

A filter and fluid technology, applied in the field of filters, can solve the problems of reduced filter performance, material waste, and affecting the service life of filters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

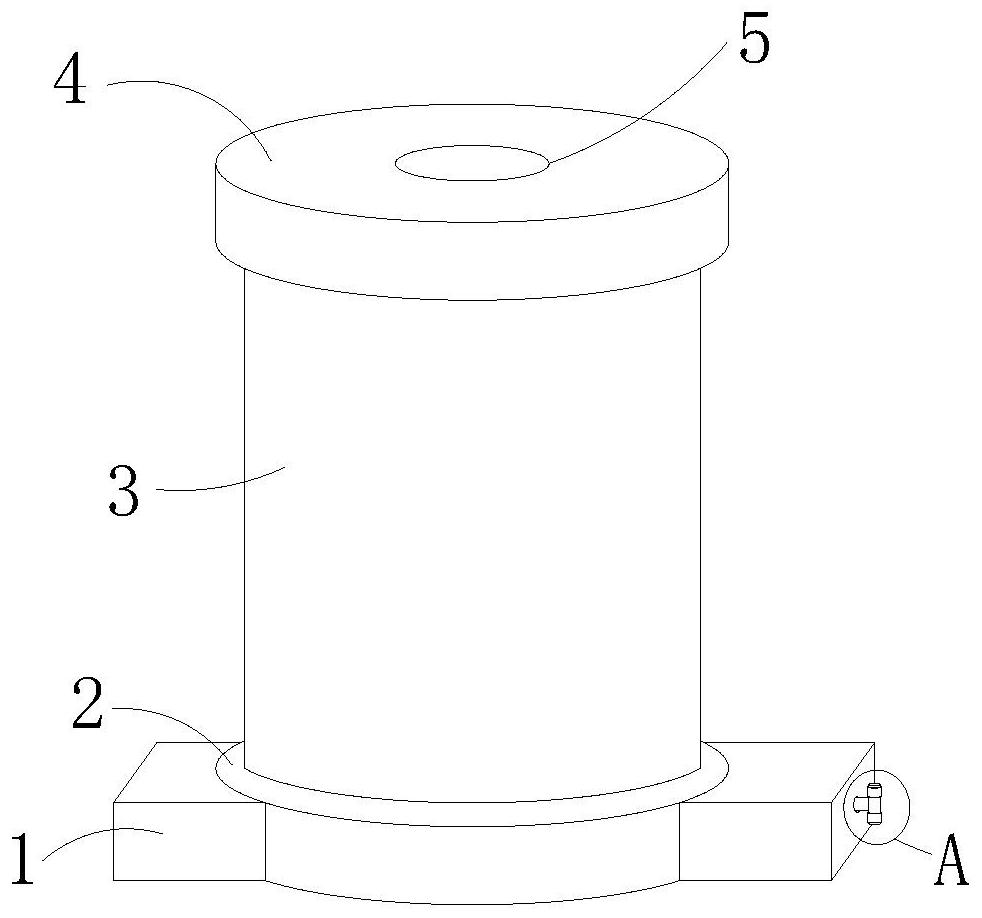

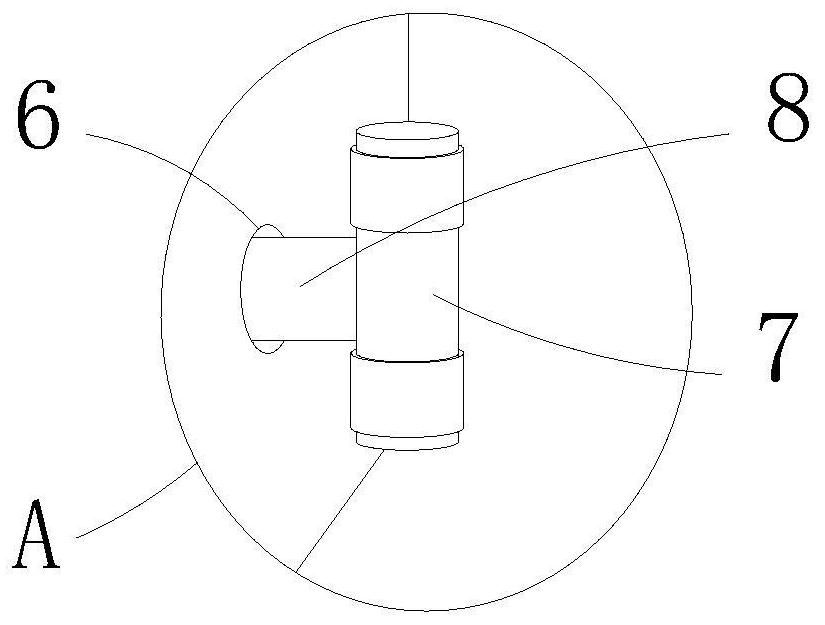

Image

Examples

Embodiment approach

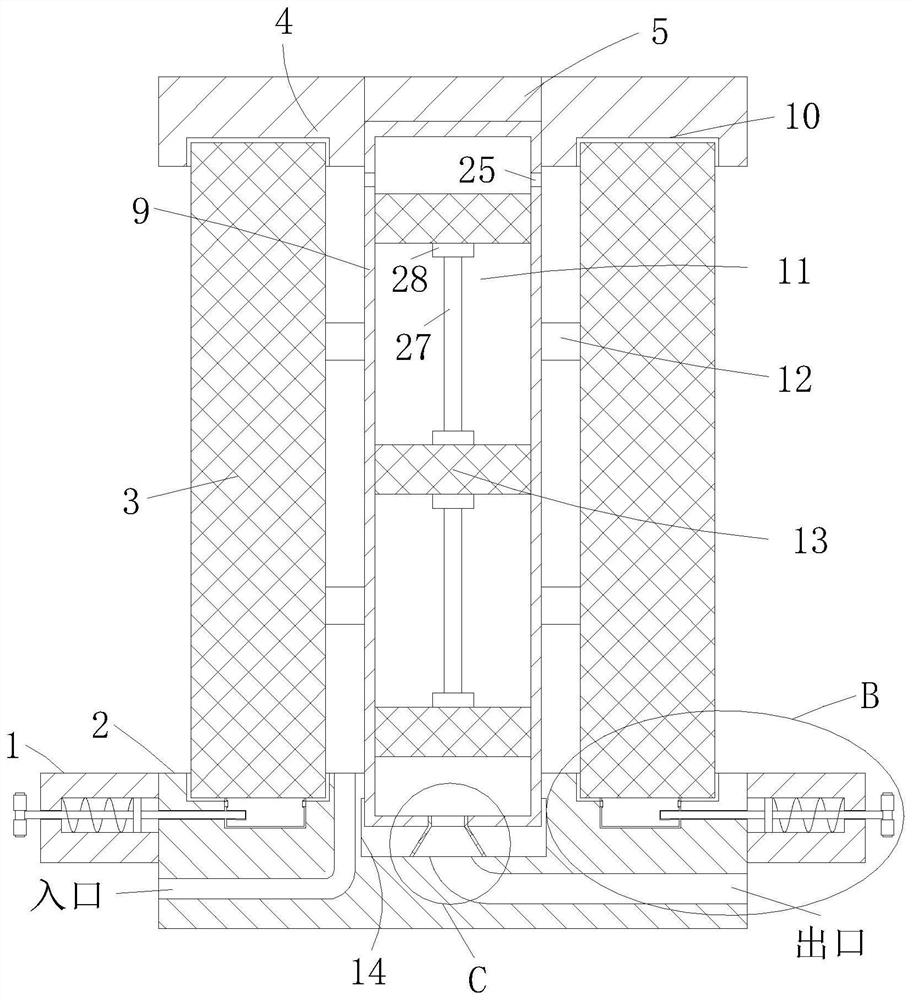

[0024] As an embodiment of the present invention, a number of filter chambers 11 are provided on the side of the connecting body 9; at least three matching filter screens 13 are installed in the filter chamber 11, and the top of the filter chamber 11 A group of first through holes 25 are provided, and a second through hole 26 is provided at the lower end of the filter chamber 11; the second through holes 26 communicate with the outlet; cavity; the number of meshes of the filter gauze 13 gradually increases from top to bottom. When working, when the fluid medium with a certain pressure passes through the filter element 3, due to the resistance of the filter element 3, a pressure difference will be generated on the inner and outer walls of the filter element 3, and the pressure difference will cause a small amount of broken fibers in the filter element 3 to flow out with the fluid medium. The filtering effect of the filter, and through opening a number of filtering through cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com