Combined type construction site exit passageway

A technology for construction sites and safe passages, applied in construction, building structure, construction material processing and other directions, can solve problems such as a lot of time and manpower, potential safety hazards, and wastage of personnel, so as to improve construction efficiency, improve safety, and improve installation. Easy and quick disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

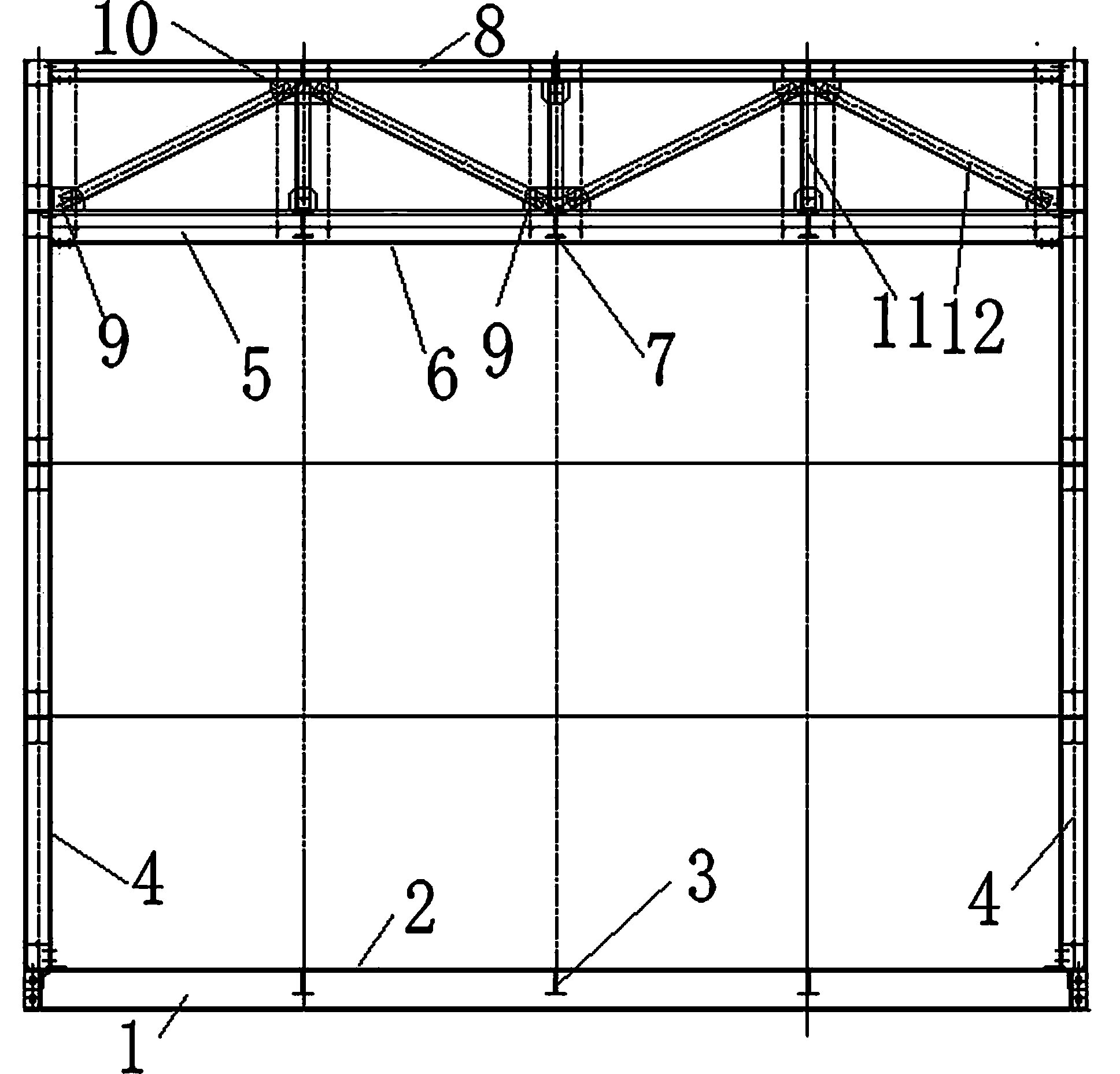

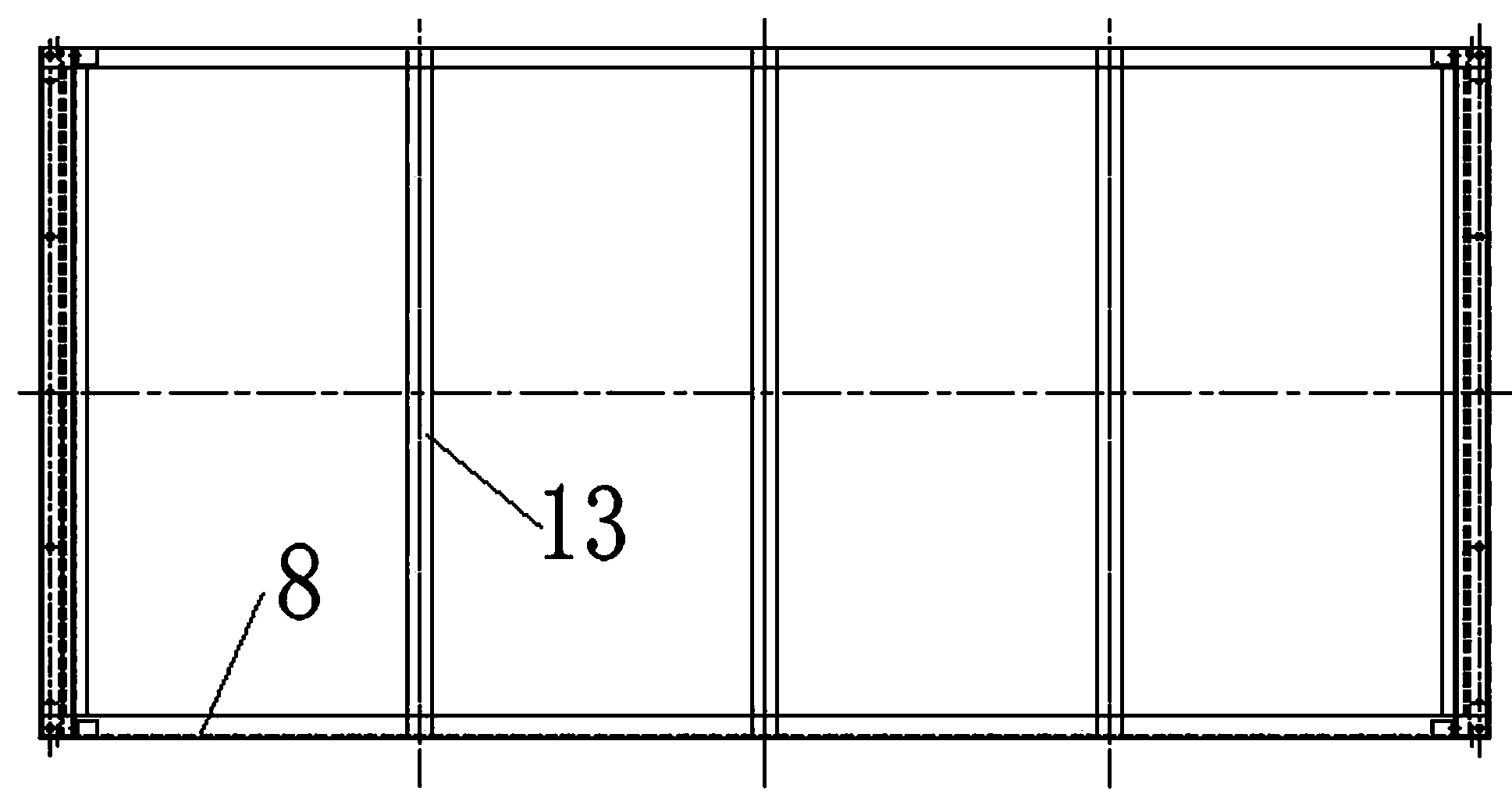

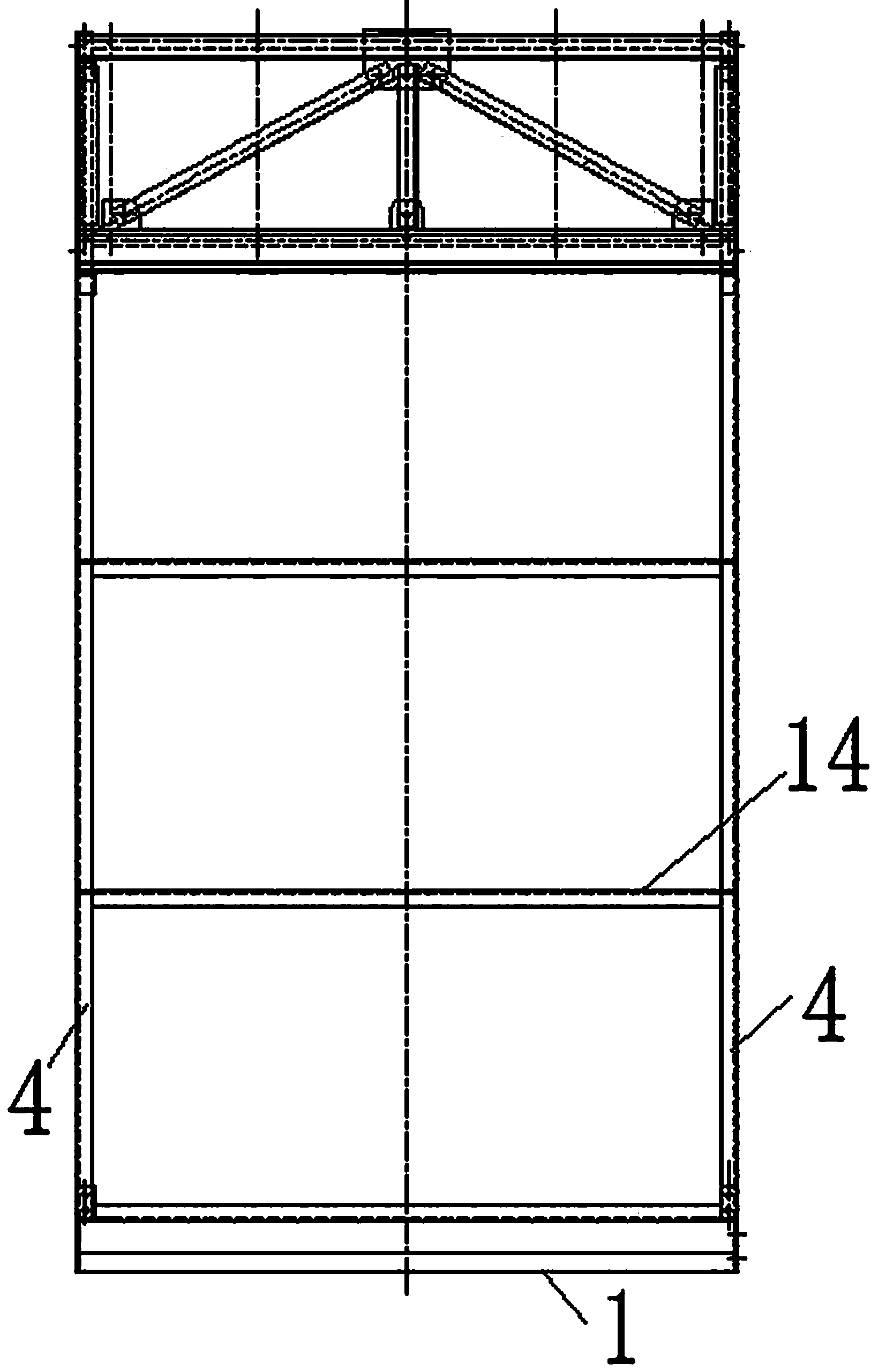

[0014] Attached below figure 1 , attached figure 2 , attached image 3 The present invention will be further described.

[0015] The combined construction site safety passage includes a rectangular bottom frame 1 formed by four I-shaped steels connected by bolts, a vertical pole 4 vertically fixed to the four corners of the bottom frame 1 by bolts, and four I-shaped steel Steel is connected by bolts to form a rectangular protective frame 5. The outer dimensions of the protective frame 5 are consistent with those of the bottom frame 1. The tops of the four vertical rods 4 are fixed on the four corners of the bottom of the protective frame 5 by bolts. , the bottom frame 1 is covered and fixed with a checkered steel plate 2 , and the protective frame 5 is covered and fixed with a steel plate 6 . The protective frame 5 can effectively block the falling objects through the steel plate 6, prevent the falling objects from injuring the construction personnel, and improve the safet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com