The Method of Measuring the Relative Displacement of Butt-jointed Parts by Reflecting Conical Surface

A technology of reflection cone and relative displacement, which is applied to measurement devices, instruments, optical devices, etc., can solve the problems of complicated installation and operation and high cost, and achieve the effect of simple data processing, simple operation and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The method of measuring the relative displacement of the butt joint by reflecting the conical surface is realized through the following steps:

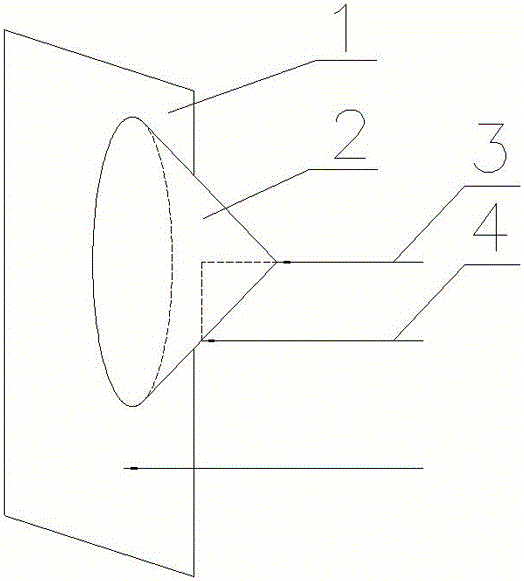

[0014] 1) Set a reflective plane 1 perpendicular to the docking axis on one of the docking parts, and set a reflective conical surface 2 whose busbar forms an angle θ with the reflecting plane 1 on the side of the reflecting plane 1 facing the other docking part;

[0015] 2) Set the first laser displacement sensor and the second laser displacement sensor on the other docking part; the light emitted by the first laser displacement sensor is perpendicular to the reflection plane 1, and the light emitted by the second laser displacement sensor is parallel to The light emitted by the first laser displacement sensor is directed to the apex of the reflective conical surface 2, and the readings of the two laser sensors are set to 0 at this time;

[0016] 3) When the axial or / and radial relative displacement occurs between the two dock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com