An on-site detection method of pressure welding positioning defects for a strain clamp

A tension clamp, on-site detection technology, used in measuring devices, using sonic/ultrasonic/infrasonic waves to analyze solids, instruments, etc. Ensure the quality of crimping construction, light and durable equipment, simple and efficient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

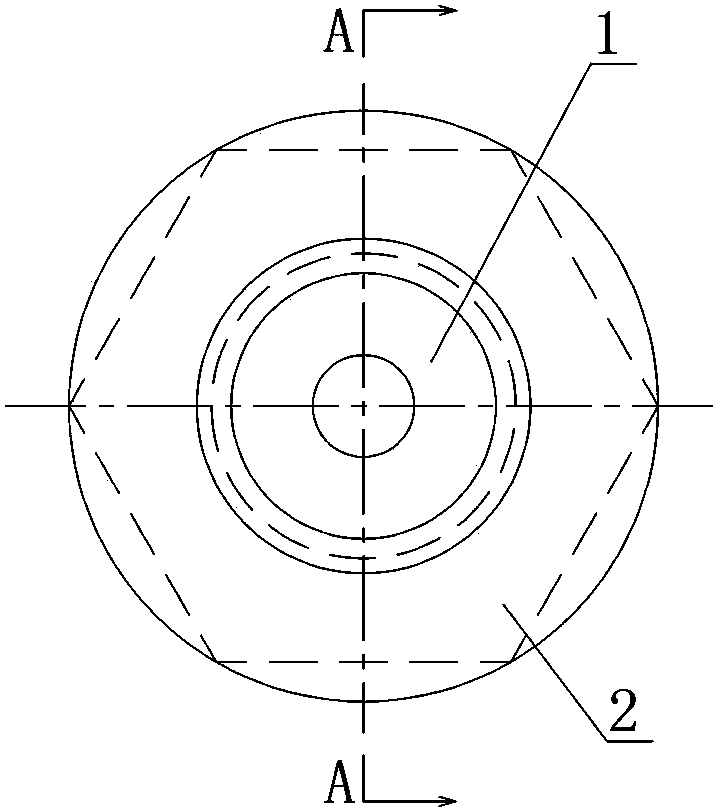

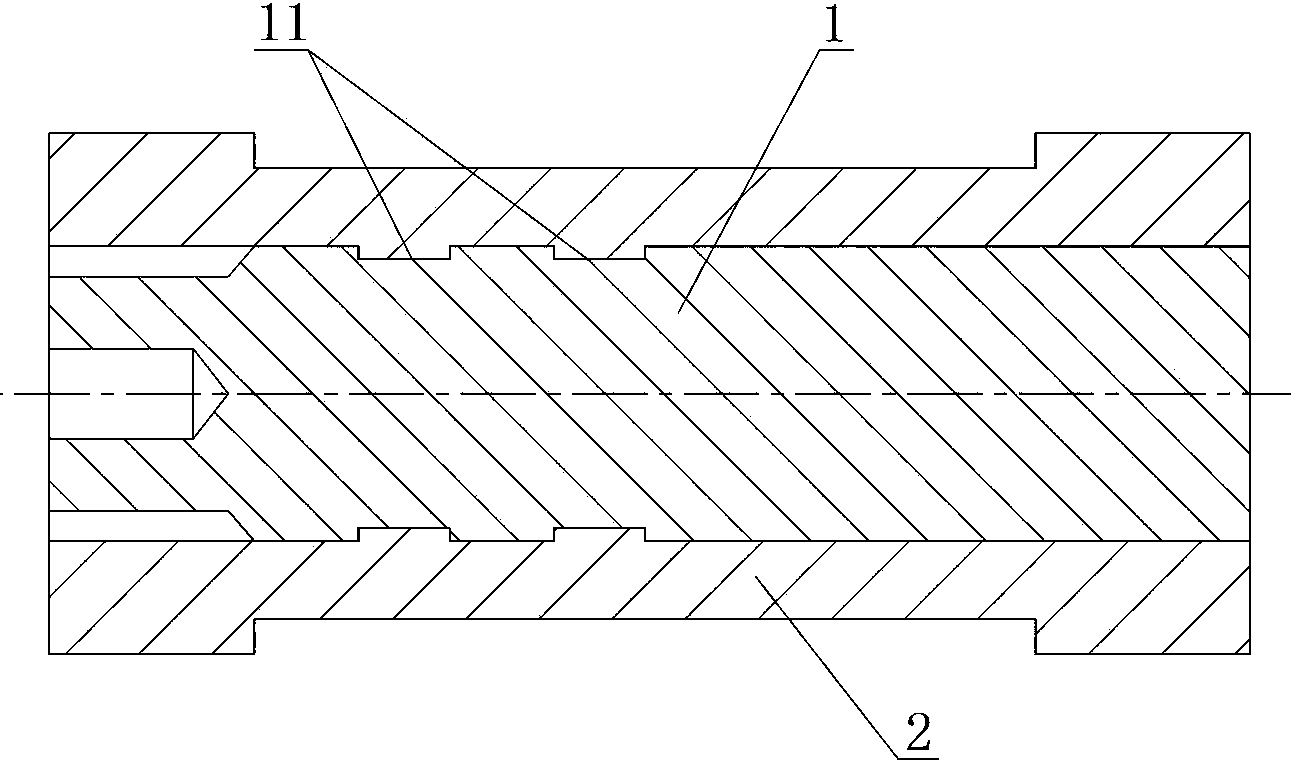

[0022] In this embodiment, a 110kV line in Hunan Power Grid is selected for inspection and implementation at the maintenance site of the tension section. There are six crimp planes.

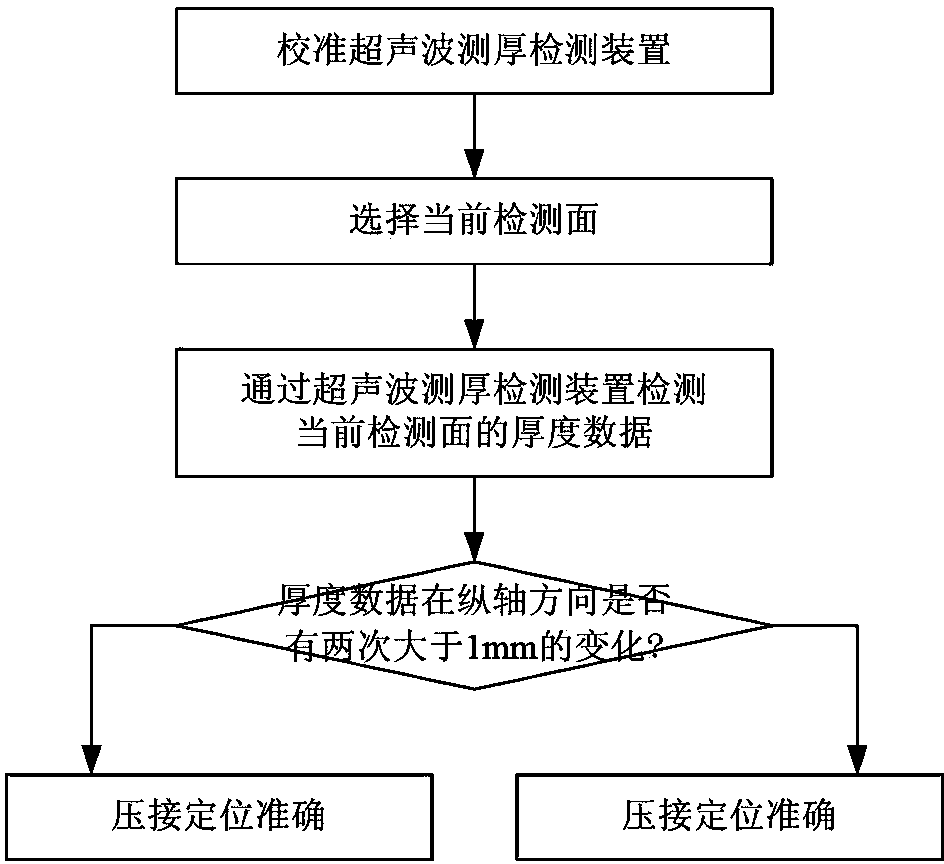

[0023] Such as image 3 As shown, the implementation steps of the on-site detection method for crimping positioning defects of tension clamps in this embodiment are as follows:

[0024] 1) Calibrate the ultrasonic thickness measurement device;

[0025] 2) Align the tension clamp to be detected for detection, select a crimping plane of the tension clamp to be detected as the current detection surface, and use the ultrasonic thickness measurement device to detect the thickness data of the current detection surface in the direction of the vertical axis Whether there are two changes equal to the depth of the groove on the steel anchor in the tension clamp, if so, it is determined that the crimping positioning of the tension clamp is accurate, otherwise it is determined that there is a crimping posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com