A method for treating the joint surface of plexiglass products with built-in three-dimensional objects

A plexiglass and processing method technology, applied in the field of plexiglass product processing, can solve the problems of product quality impact, easy generation of bubbles, low product authenticity rate, etc., and achieve the effect of improving enterprise economic benefits, improving quality, and no technical difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

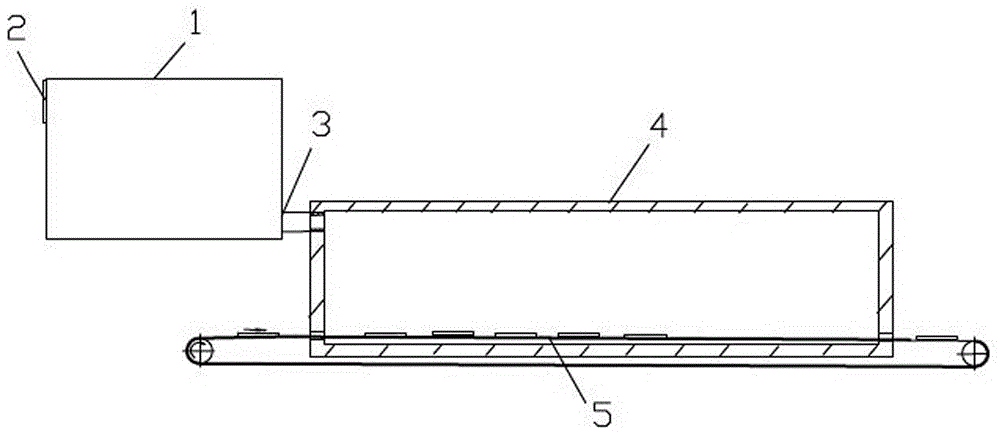

Image

Examples

Embodiment 1

[0021] A method for processing the bonding surface of a plexiglass product with a built-in three-dimensional object, comprising the following steps:

[0022] In the first step, an adhesive is coated on the cutting surface of the cut plexiglass block; the formula of the adhesive is, by weight, 15 parts of methylene chloride, 15 parts of acetic acid, and 140 parts of phenol.

[0023] In the second step, the plexiglass blocks treated in the first step are sent to the ozone treatment room for treatment. The ozone concentration in the ozone room is not less than 1 mg / dm3, and the temperature of the ozone room is 15-30°C for 3 minutes. ;

[0024] The third step is to send the plexiglass block treated in the second step into an oven and heat it to 180°C to soften the plexiglass block;

[0025] The fourth step is to place the built-in three-dimensional object in the accommodation space formed by at least two organic glass blocks, and pressurize the organic glass block as a whole, so ...

Embodiment 2

[0031] A method for processing the bonding surface of a plexiglass product with a built-in three-dimensional object, comprising the following steps:

[0032] In the first step, an adhesive is coated on the cutting surface of the cut plexiglass block; the formula of the adhesive is, by weight, 20 parts of methylene chloride, 20 parts of acetic acid, and 150 parts of phenol.

[0033] In the second step, the plexiglass blocks treated in the first step are sent to the ozone treatment room for treatment. The ozone concentration in the ozone room is not less than 1 mg / dm3, and the temperature of the ozone room is 15-30°C for 4 minutes. ;

[0034] The third step is to send the plexiglass block treated in the second step into an oven and heat it to 180°C to soften the plexiglass block;

[0035] The fourth step is to place the built-in three-dimensional object in the accommodation space formed by at least two organic glass blocks, and pressurize the organic glass block as a whole, so ...

Embodiment 3

[0041] A method for processing the bonding surface of a plexiglass product with a built-in three-dimensional object, comprising the following steps:

[0042] In the first step, an adhesive is coated on the cutting surface of the cut plexiglass block; the formula of the adhesive is, by weight, 25 parts of methylene chloride, 25 parts of acetic acid, and 160 parts of phenol.

[0043] In the second step, the plexiglass block treated in the first step is sent to the ozone treatment room for treatment. The ozone concentration in the ozone room is not less than 1 mg / dm3. After 5 minutes of treatment, the temperature of the ozone room is 15-30 ° C. ;

[0044] The third step is to send the plexiglass block treated in the second step into an oven and heat it to 180°C to soften the plexiglass block;

[0045] The fourth step is to place the built-in three-dimensional object in the accommodation space formed by at least two organic glass blocks, and pressurize the organic glass block as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com