Fully automatic car unloading system

A fully automatic, automotive technology, applied in the field of automobile cargo unloading system, can solve the problems of incomplete unloading of materials, influence of the connection fastness of the trailer body and the flap platform, etc., to achieve good use effect, low labor intensity, and easy operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the drawings and specific implementations:

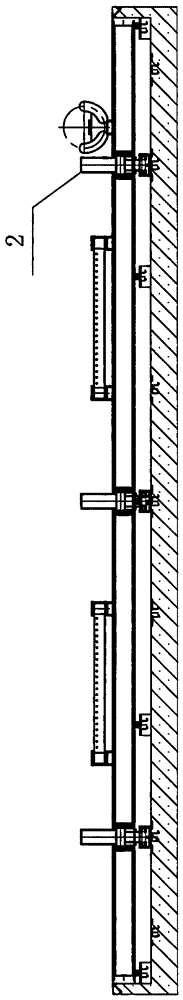

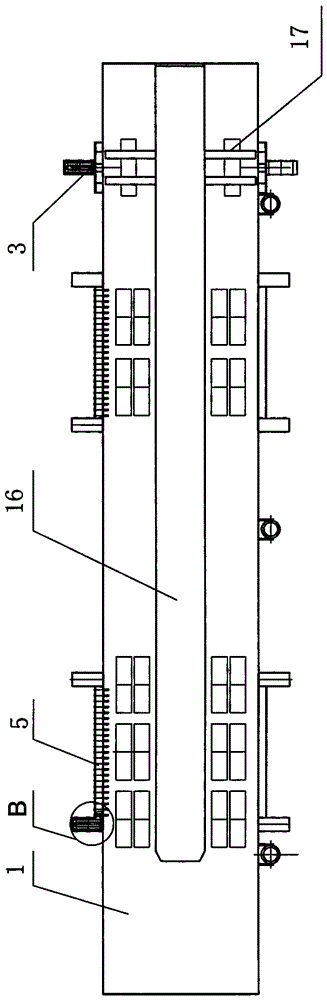

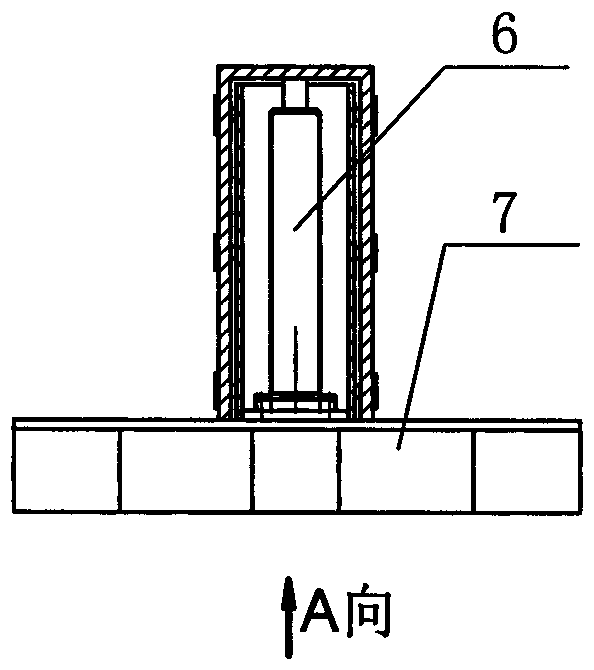

[0023] Such as Figure 1 to Figure 5 Shown: the present invention includes a flap platform 1, a lifting cylinder 2 connected to the flap platform 1, and an anti-rollover device. The anti-rollover device includes a front wheel locking mechanism 3 and The rear wheel lock mechanism 5 corresponding to the position of the rear wheels. The front wheel lock mechanism 3 includes a lateral drive 6 and a gear ring 7 fixedly connected to the output end of the lateral drive 6. The shape and size of the gear ring 7 and the shape of the tire In accordance with the size, the lateral drive 6 in the front wheel locking mechanism 3 is a hydraulic cylinder or cylinder; the rear wheel locking mechanism 5 includes a lateral drive 8, a gear beam 9 fixedly connected to the output end of the lateral drive 8, and The multiple sets of pinch wheel assemblies on the crossb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com