Warp feeding device of rapier loom

A rapier loom and warp let-off technology, which is applied in looms, textiles, textiles, and papermaking, can solve problems such as lack of tension and production impact, and achieve the effects of reducing procedures, improving work efficiency, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

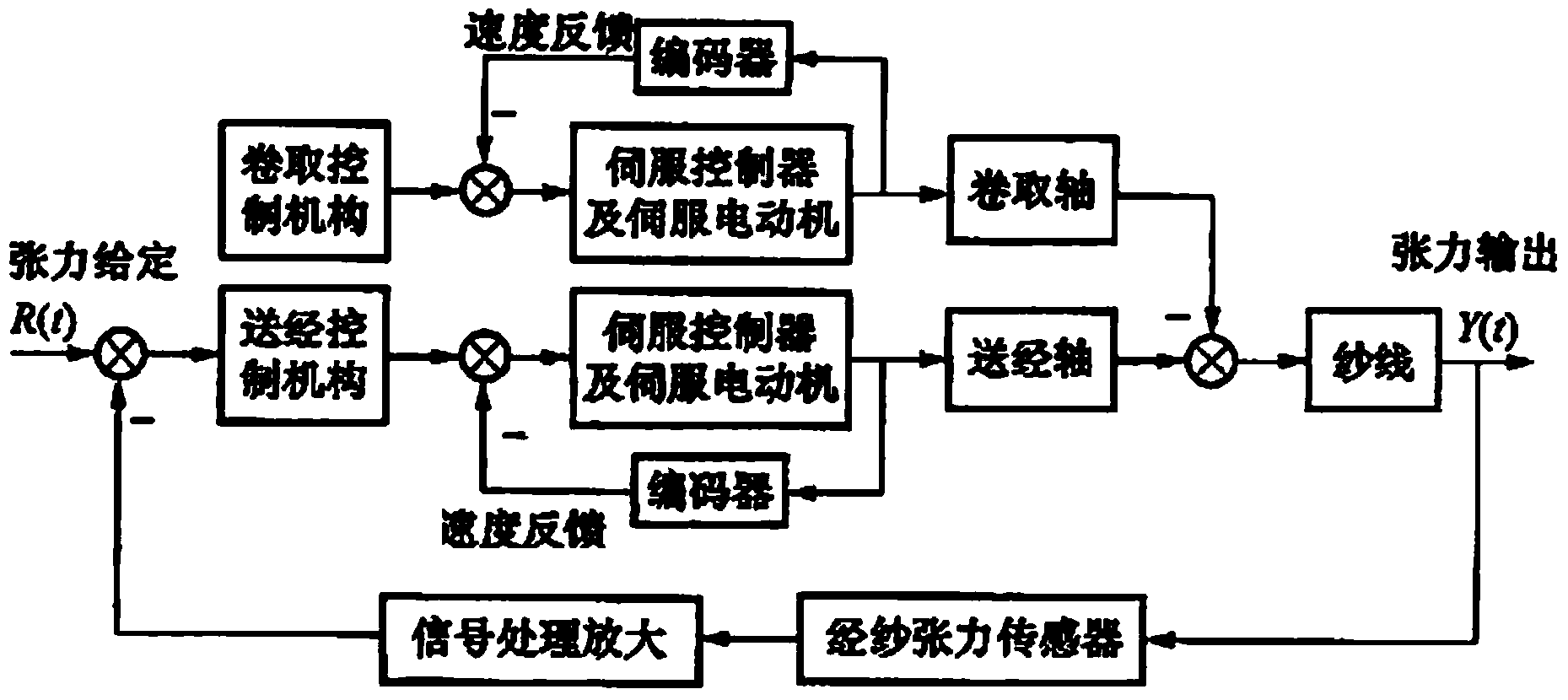

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

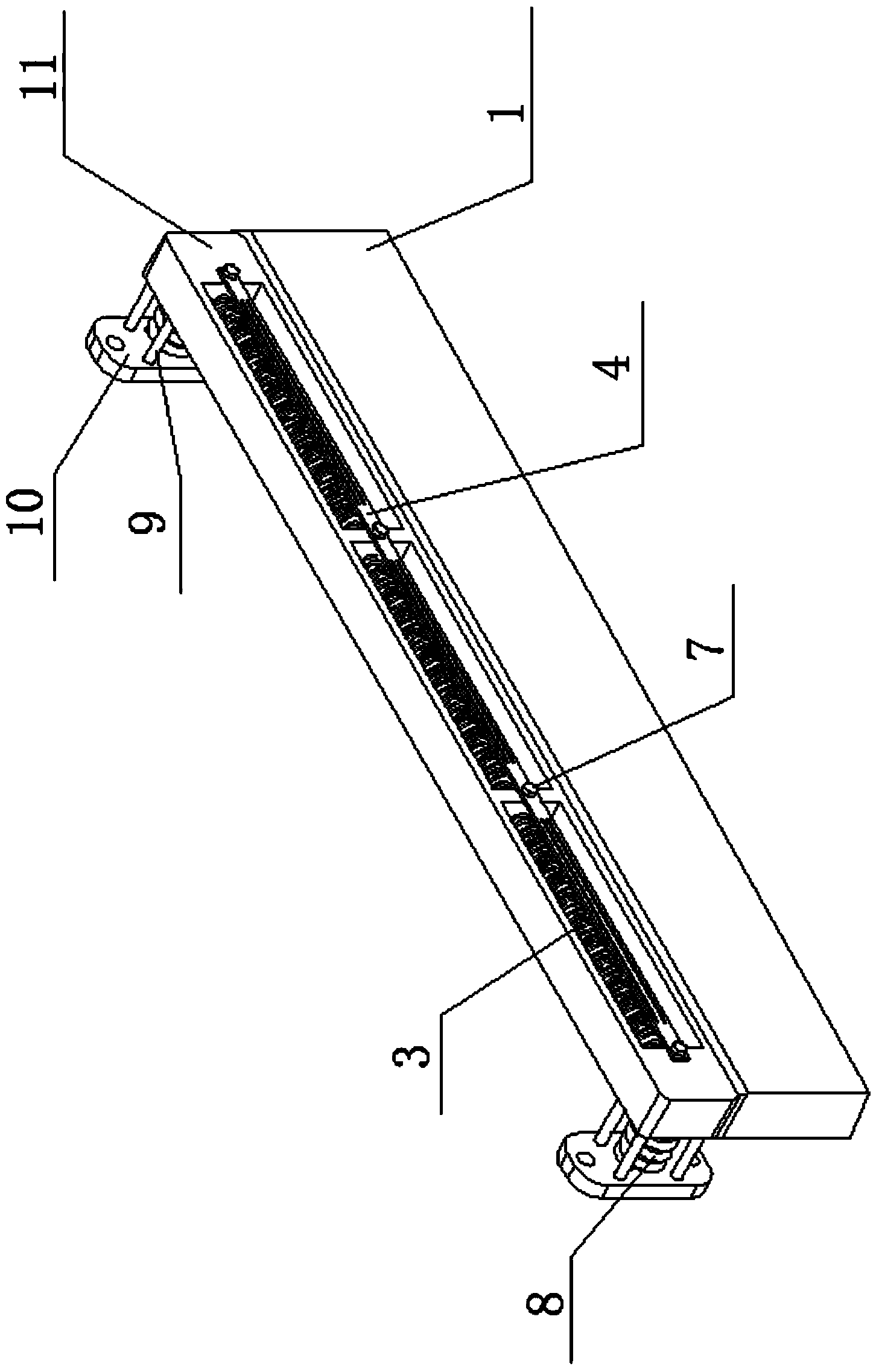

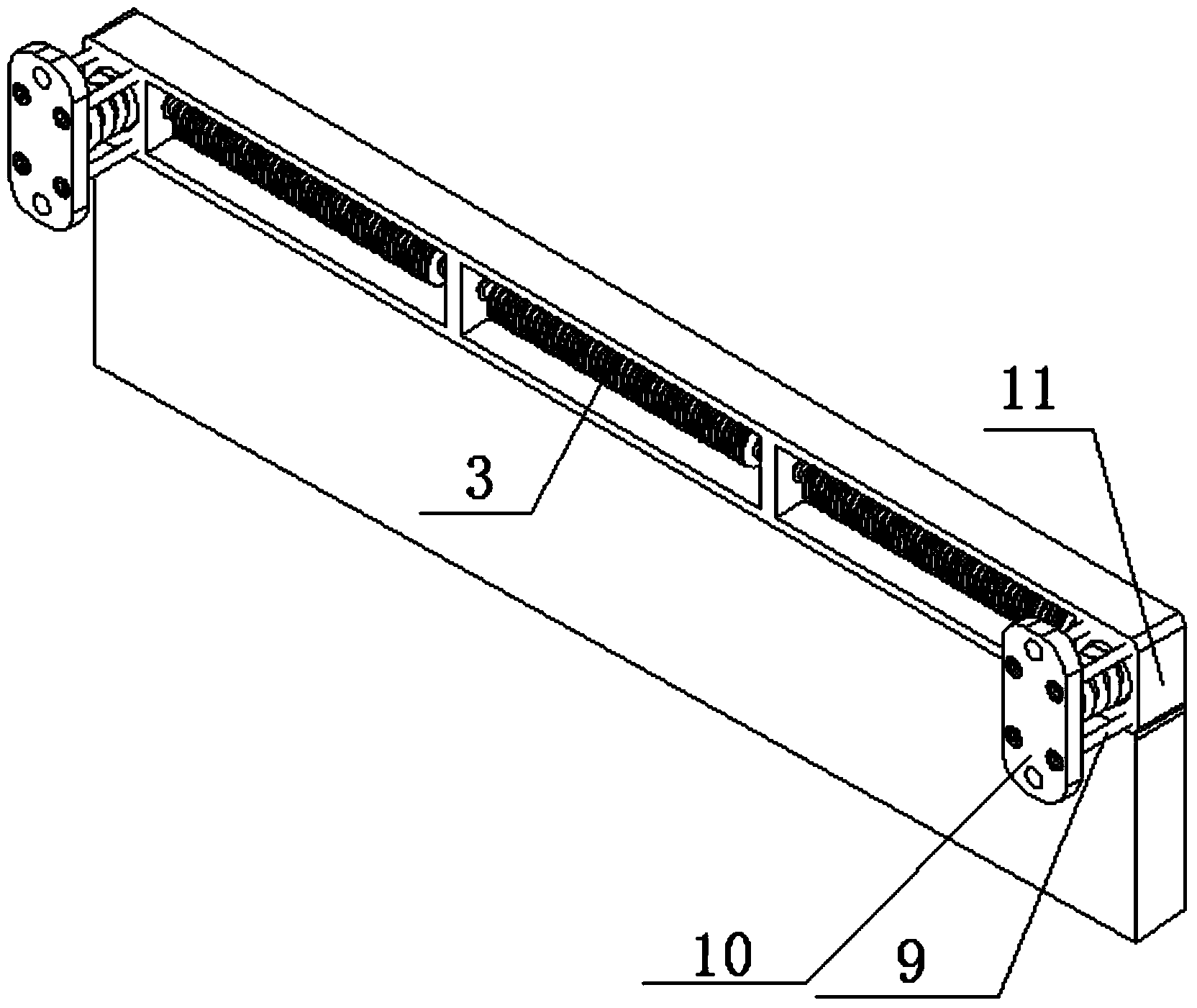

[0032] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] A let-off device of a rapier loom, such as Figure 2-7 As shown, it includes a support base 1 and a fixing device 10. The upper surface of the support base 1 is slidably connected to several supports 11, and a mandrel 2 is installed between two adjacent supports 11. Distributed clamping pieces 3, between the outermost clamping piece 3 and its adjacent bracket 11, an adjusting gasket 6 and a first spring 5 are arranged in sequence; The sheet 4 is provided with horizontal elongated through holes arranged in parallel up and down, for guiding the direction of the warp 12, and ensuring that the warp 12 will not come out from between the clamping sheets 3 during work;

[0034] The distance between two adjacent clamping pieces 3 can only pass through two warps 12, and the warp 12 contacts the adjacent clamping pieces 3 to generate friction, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com