Woolen blanket, process for manufacturing same and loop velvet cutting machine for weaving woolen blanket

A wool and knitting machine technology, used in blankets, cut loops, textiles and papermaking, etc., can solve the problems of uneven color, wool length, uneven density, low density, etc., to achieve uniform color and length, comfortable touch, high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

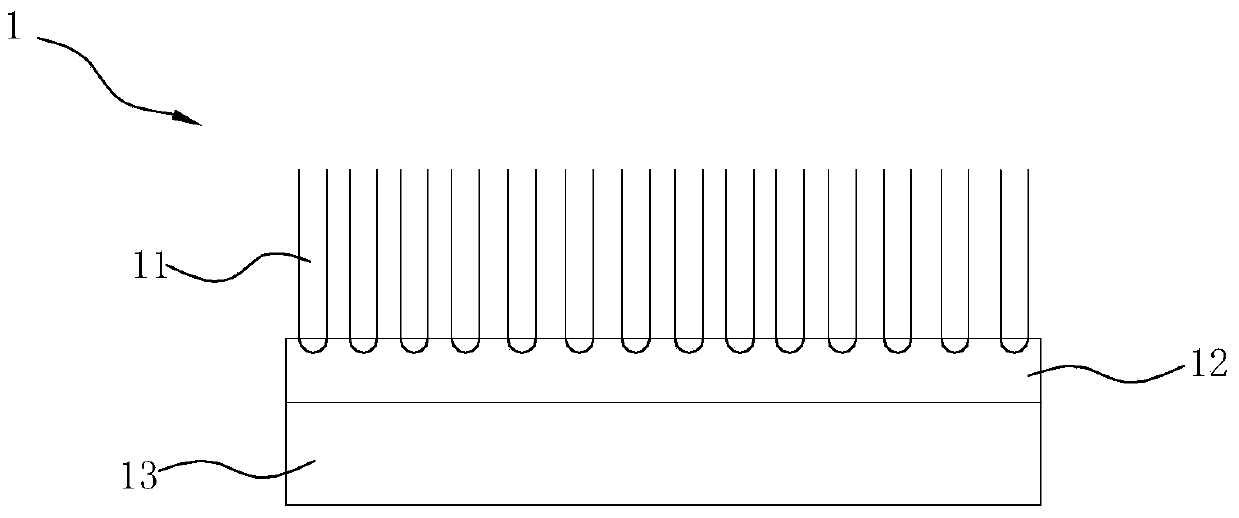

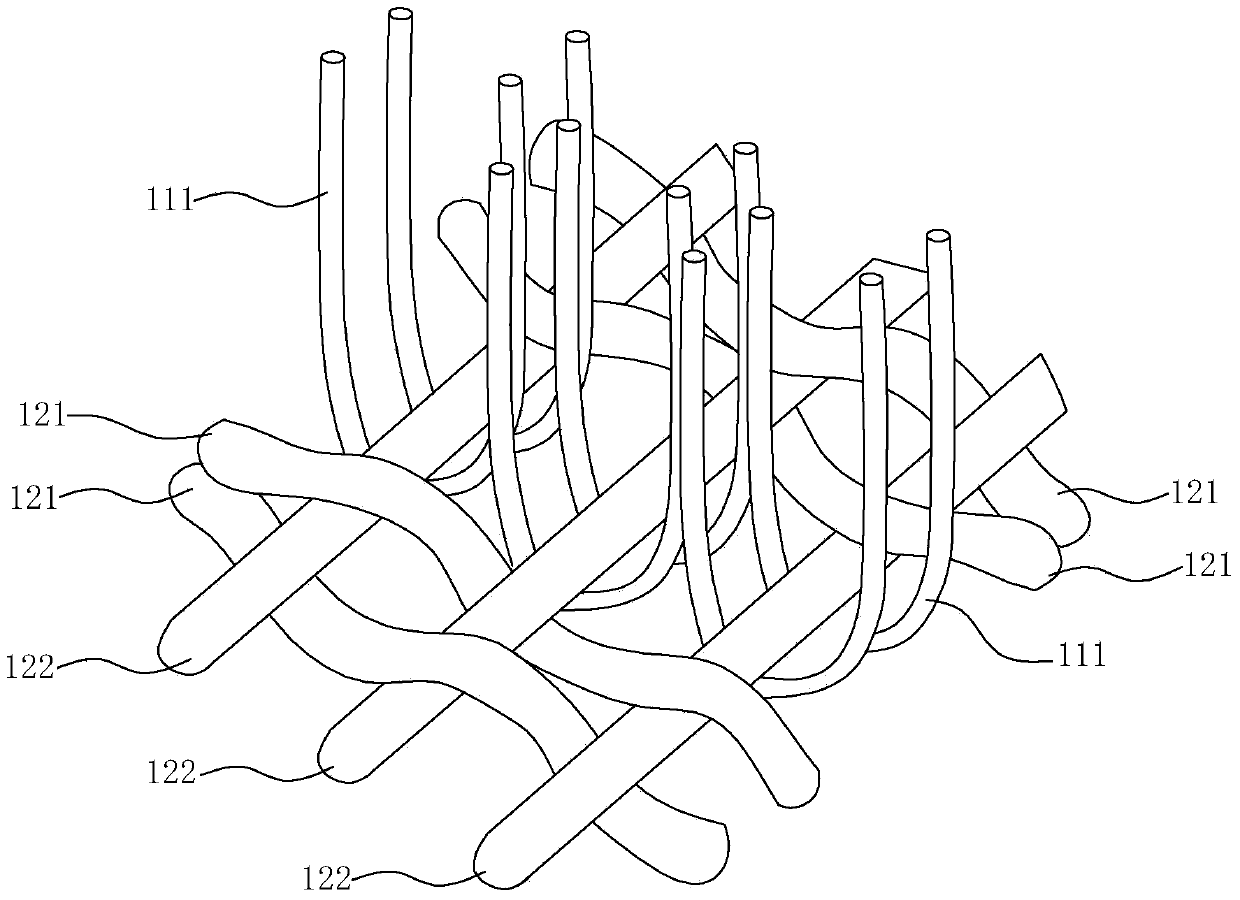

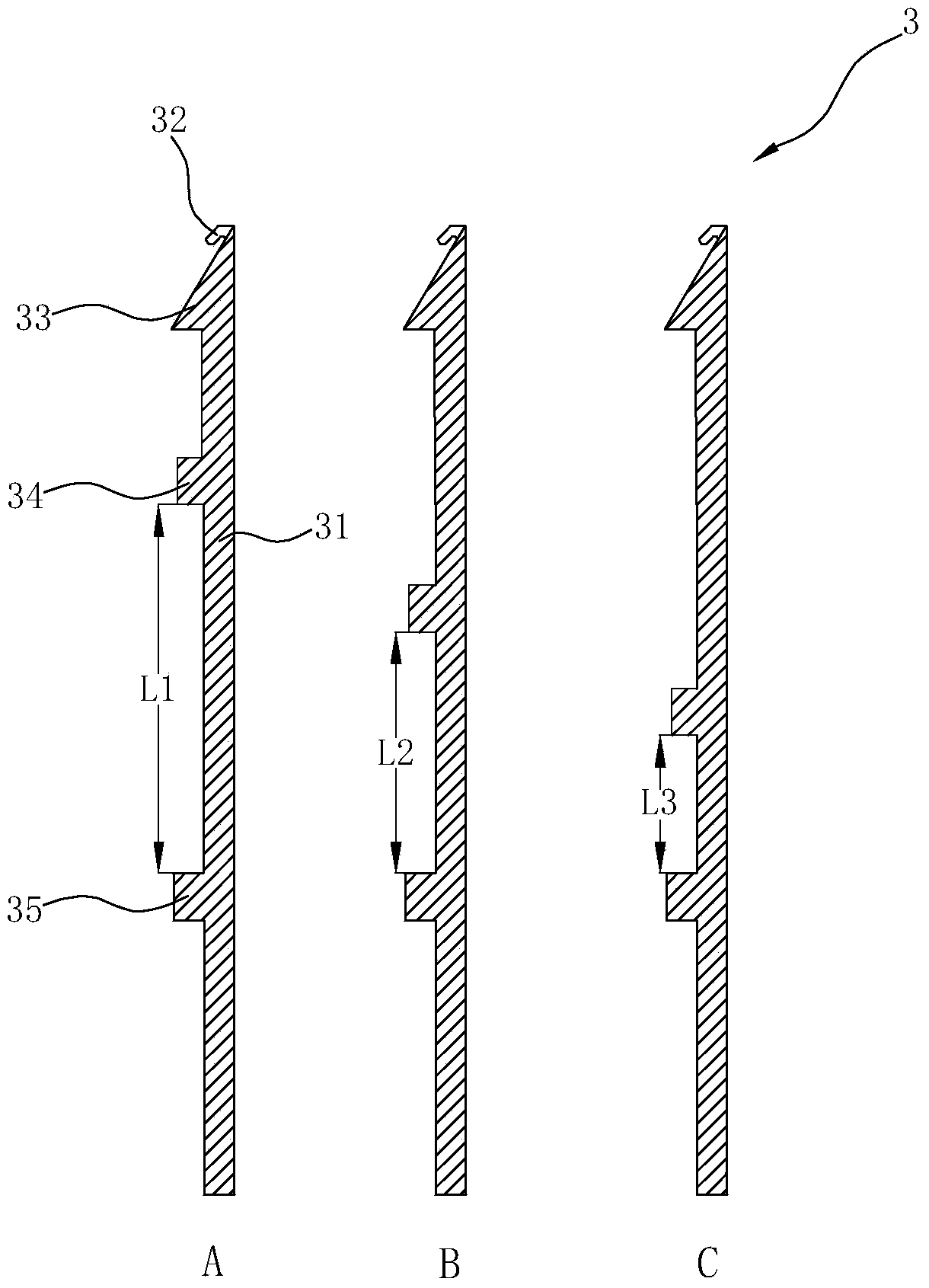

[0033] Such as figure 1 , 2 As shown, the fleece blanket 1 of the present embodiment includes a down layer 11, a polyester layer 12 and a composite skin layer 13, the thickness of the down layer 11 is 15 mm to 30 mm, and the down layer 11 is woven on the upper surface of the polyester layer 122, and the polyester layer 12 The lower surface is connected to the composite cortex, and the polyester layer 12 is woven from warp threads 121 and weft threads 122, and a pair of warp threads 121 are alternately woven into the top and bottom of each weft thread 122 in the form of plain weaving, and two adjacent pairs of warp threads 121 There are at least two U-shaped pile threads 111 woven on the weft threads 122 between them. In this embodiment, two U-shaped pile threads 111 are woven on the weft threads 122 between two adjacent pairs of warps 121, T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com