bidirectional gear motor

A two-way gear and motor technology, used in rotary piston engines, rotary or oscillating piston engines, machines/engines, etc., can solve the problem of inability to withstand radial forces and bending moments, increase the starting torque of gear motors, and difficult assembly of seals and other problems, to improve the working pressure and mechanical efficiency, improve the clearance of the axial fit, and improve the high-temperature starting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

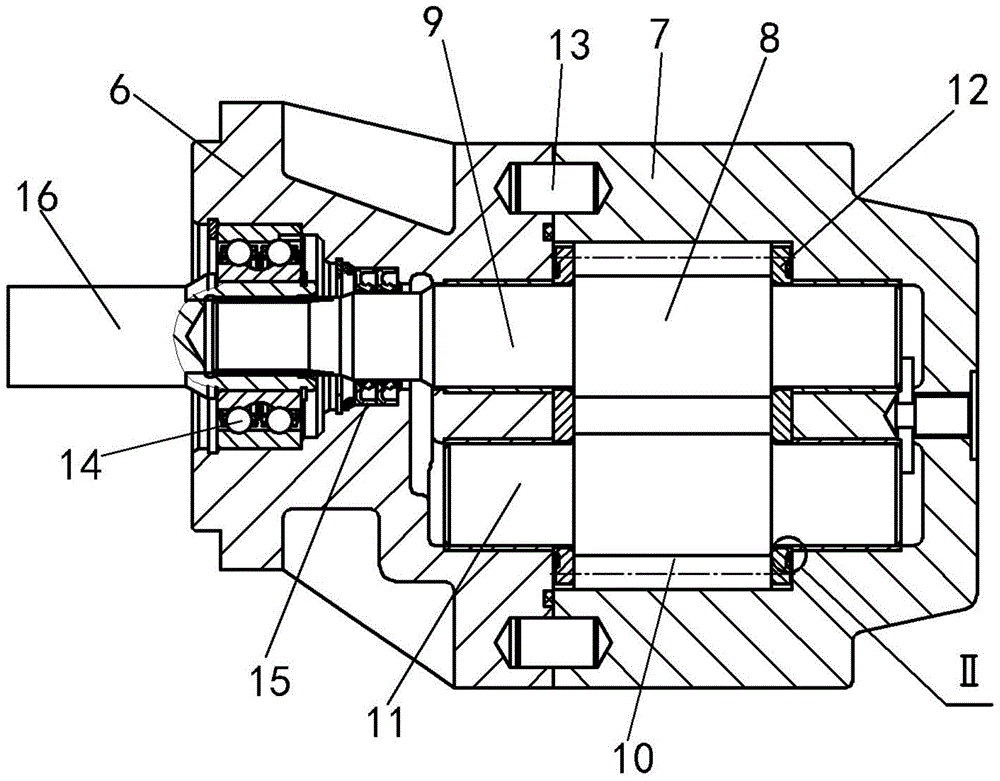

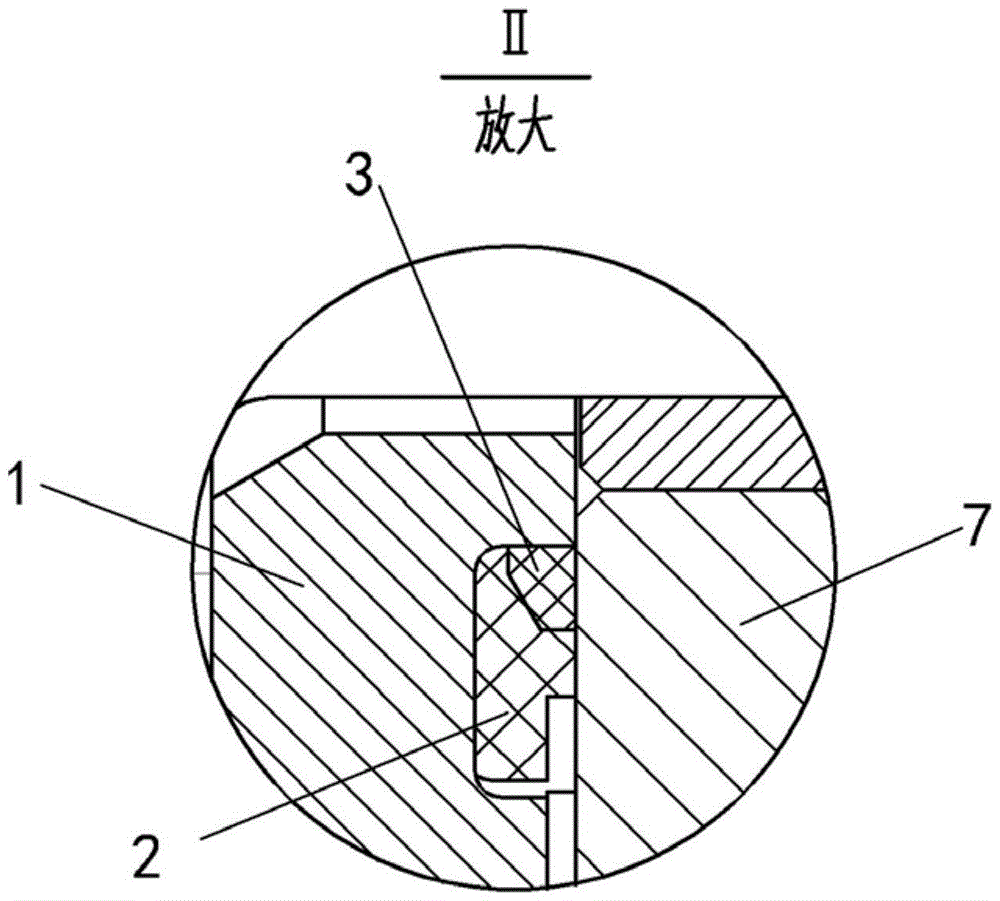

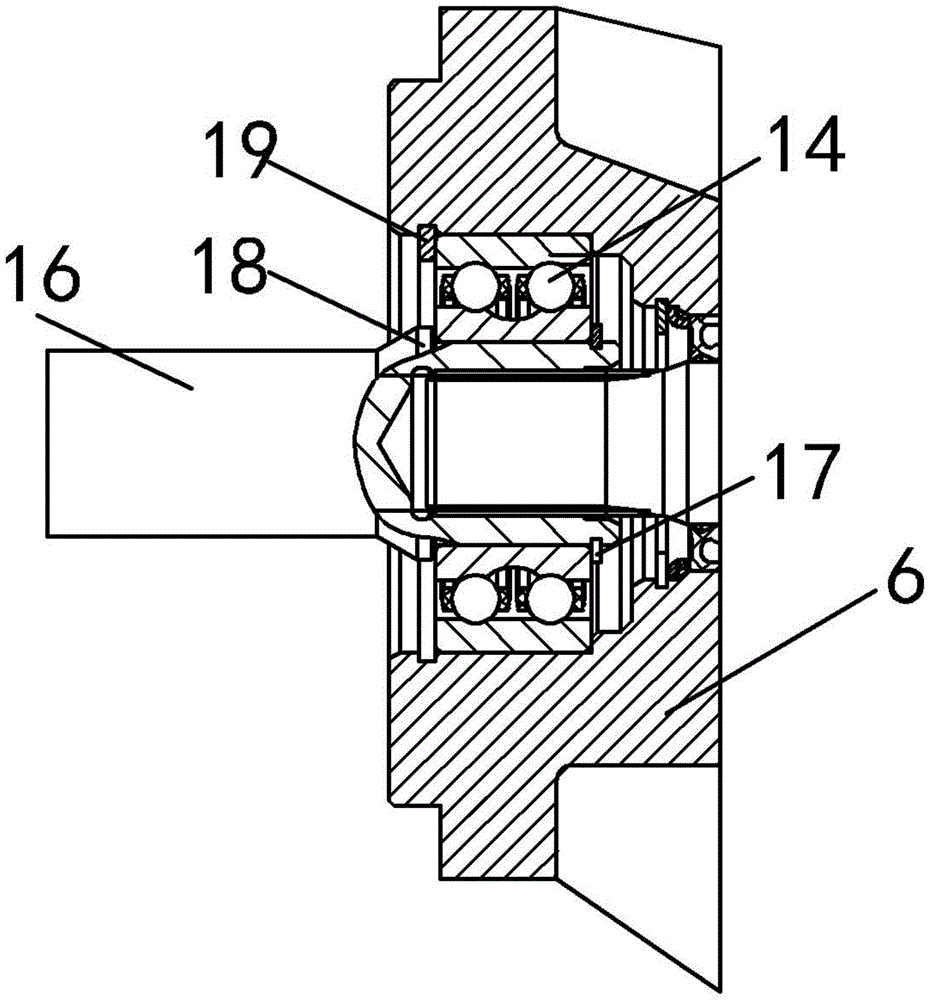

[0047] see attached picture figure 1 ~ attached Figure 9 , the bidirectional gear motor of the present invention includes a front cover 6, a housing 7, a driving gear 8, a driving gear shaft 9, a driven gear 10, a driven gear shaft 11 and a side plate 12; the housing 7 includes a left side An open trough cavity, the driving gear 8, the driving gear shaft 9, the driven gear 10, the driven gear shaft 11 and the side plate 12 are all arranged in the housing 7; the front cover 6 is fixedly arranged on the left end face of the housing 7, and close the left opening of the groove cavity; the left end of the driving gear shaft 9 passes through the front cover 6 and protrudes from the left end of the front cover 6 ; The front cover 6 is provided with a stepped inner cavity, and the driving gear shaft 9 passes through the stepped inner cavity; the left end cavity of the stepped inner cavity is set as a bearing cavity, and the stepped inner cavity The cavity at the right end of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com