Adsorption device and vacuum adsorption equipment capable of adsorbing soft object

A technology of vacuum adsorption and adsorption device, applied in mechanical equipment, suction cups, connecting components, etc., can solve problems such as inconvenient detection, warping, wrinkling, and damage to the surface of the material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

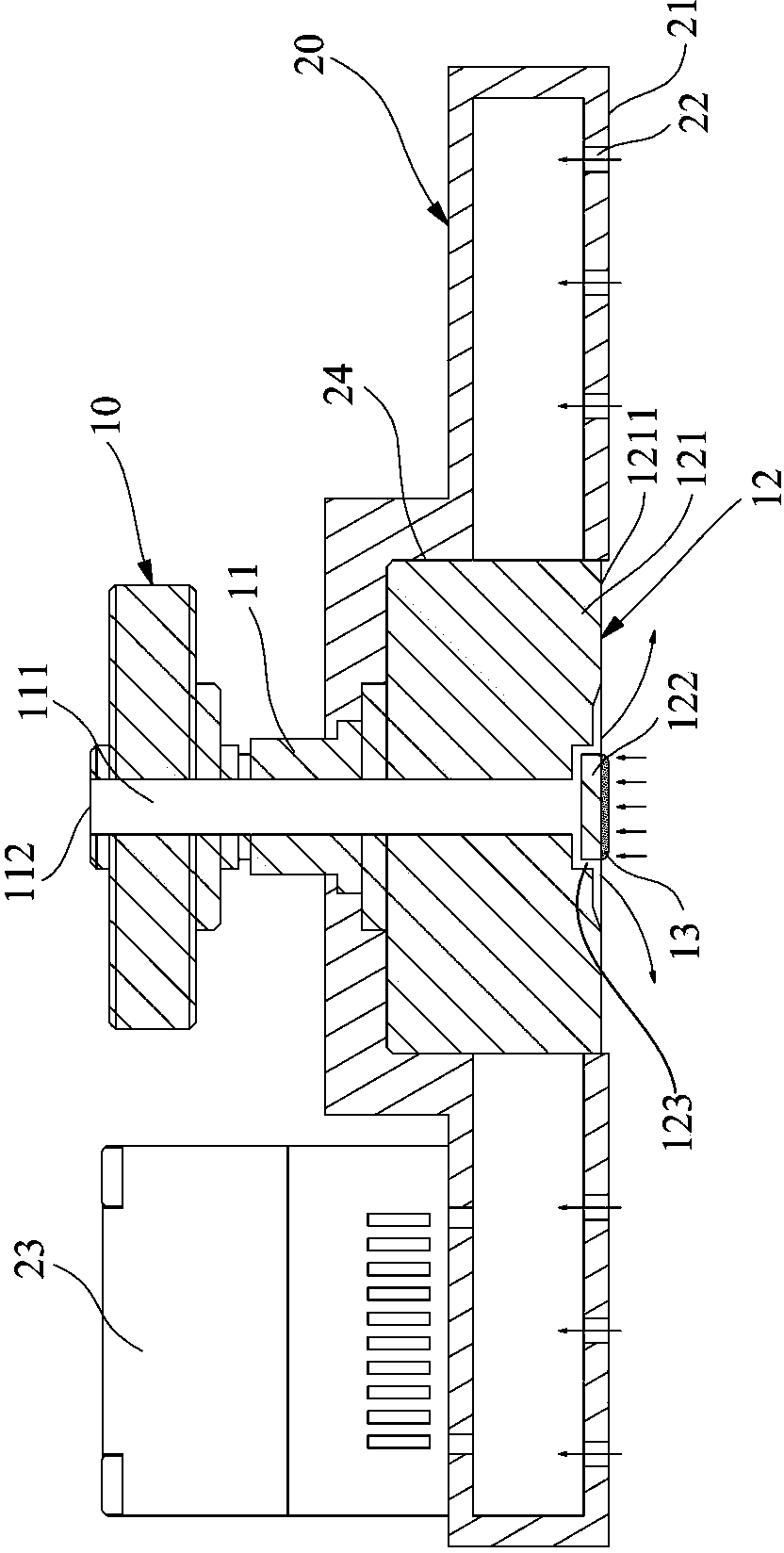

[0025] The structural features and operation methods of this case are hereby described in conjunction with illustrations for review reference. The drawings in the present invention are not necessarily drawn according to the actual scale but are exaggerated for convenience of description. These drawings and their proportions are not intended to limit the scope of the present invention.

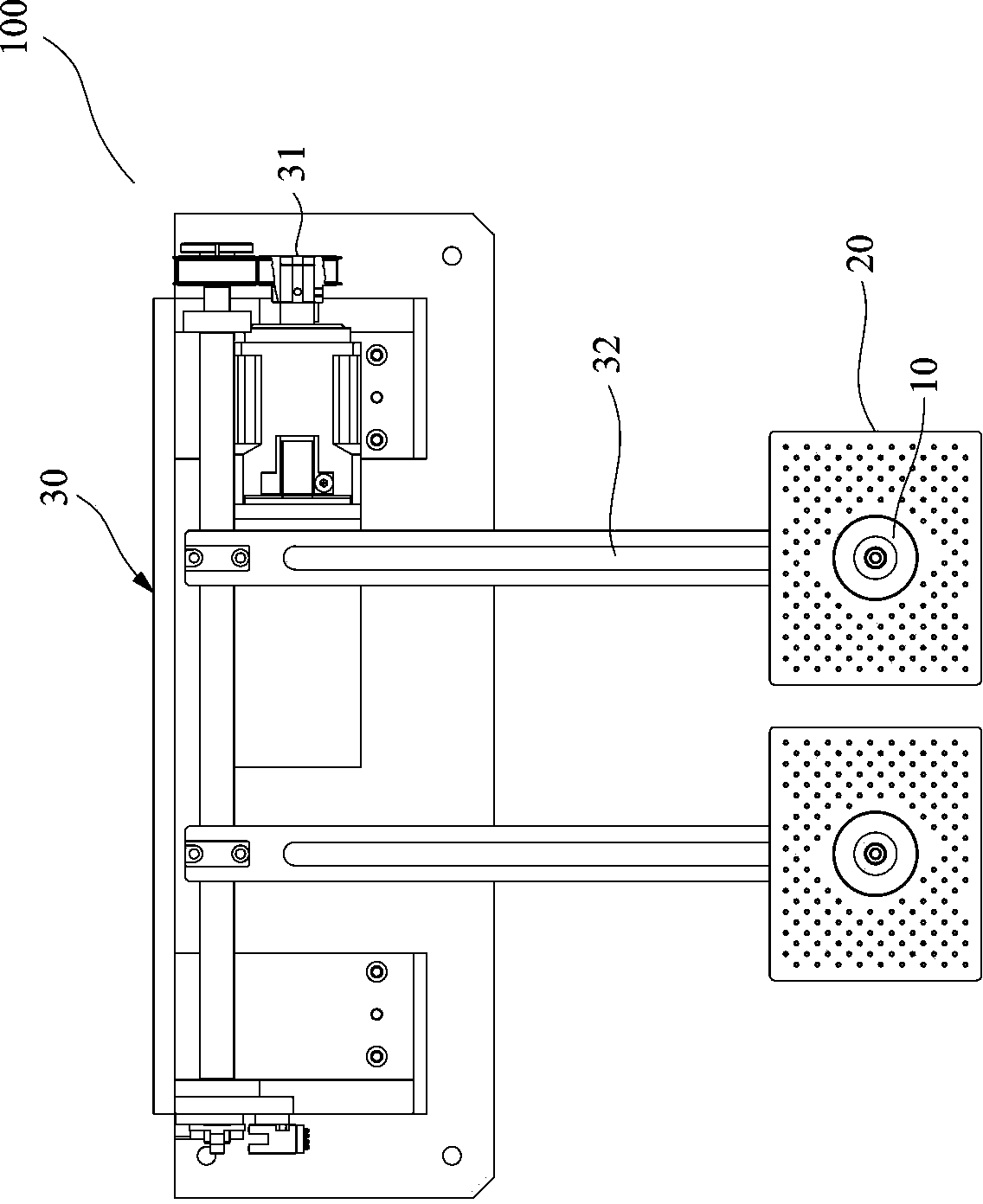

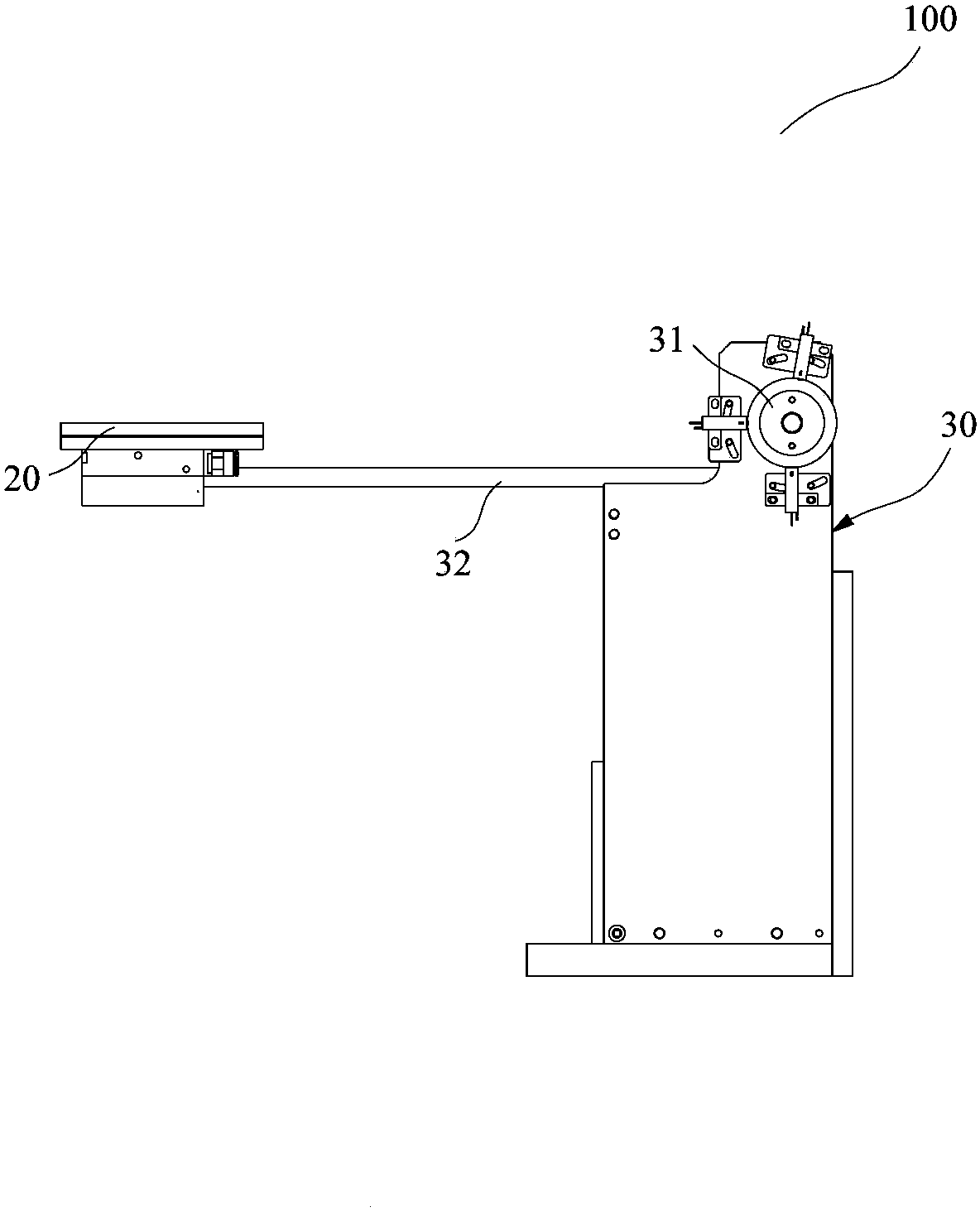

[0026] Please refer to this invention figure 1 and figure 2 , the schematic appearance of the vacuum adsorption equipment of the present invention Figure 1 , two ,as the picture shows:

[0027] The present invention provides a vacuum adsorption device 100 capable of absorbing soft objects, which is used for absorbing material sheets to achieve the purposes of transferring, flipping, and testing. The main structure of the vacuum suction device 100 includes a moving device 30 , a planar suction plate 20 connected to the moving device 30 , and a suction device 10 arranged on the planar suct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com