Tool deflection modeling method for multi-axis machining system

A technology of multi-axis machining and modeling method, applied in general control system, control/adjustment system, simulator, etc., can solve the problem of aggravated tool wear and even edge chipping, is not suitable for attitude-changing machining, and does not fully consider multi-axis machining systems issues of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

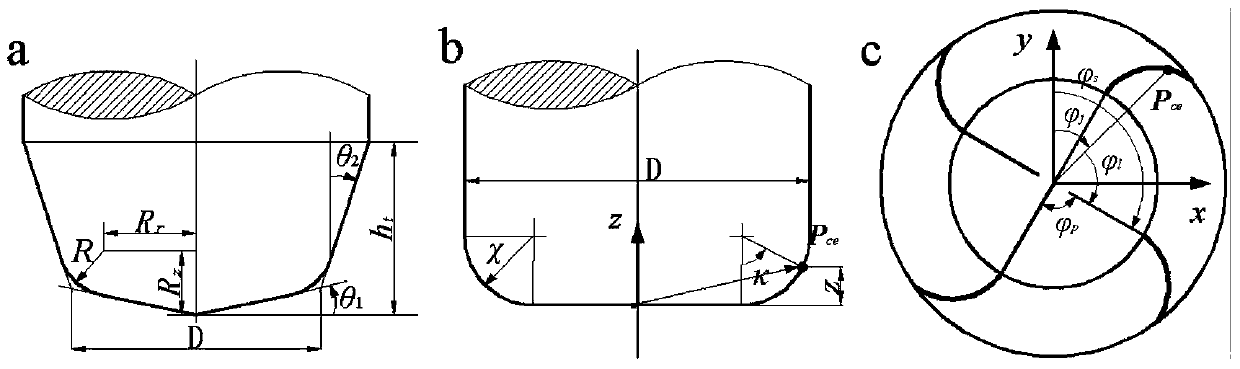

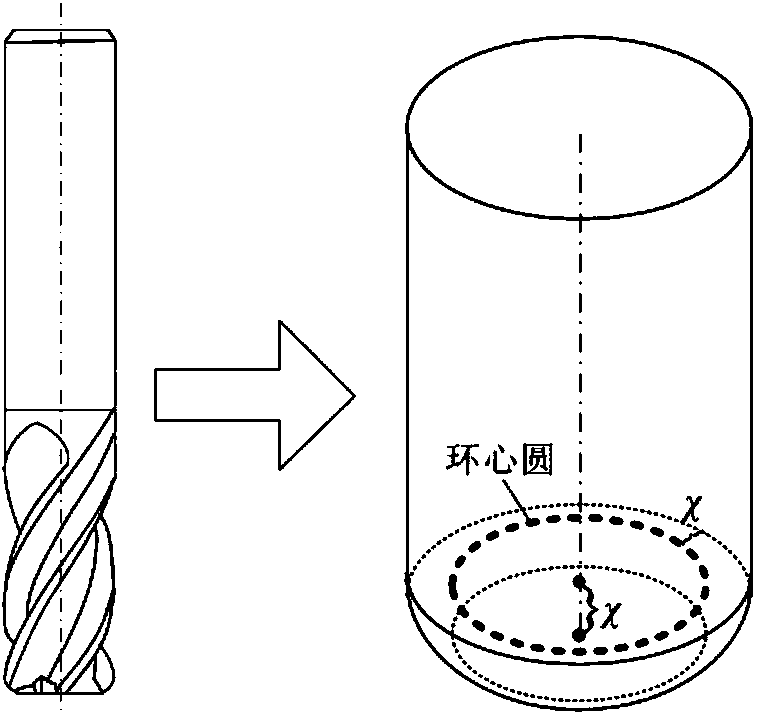

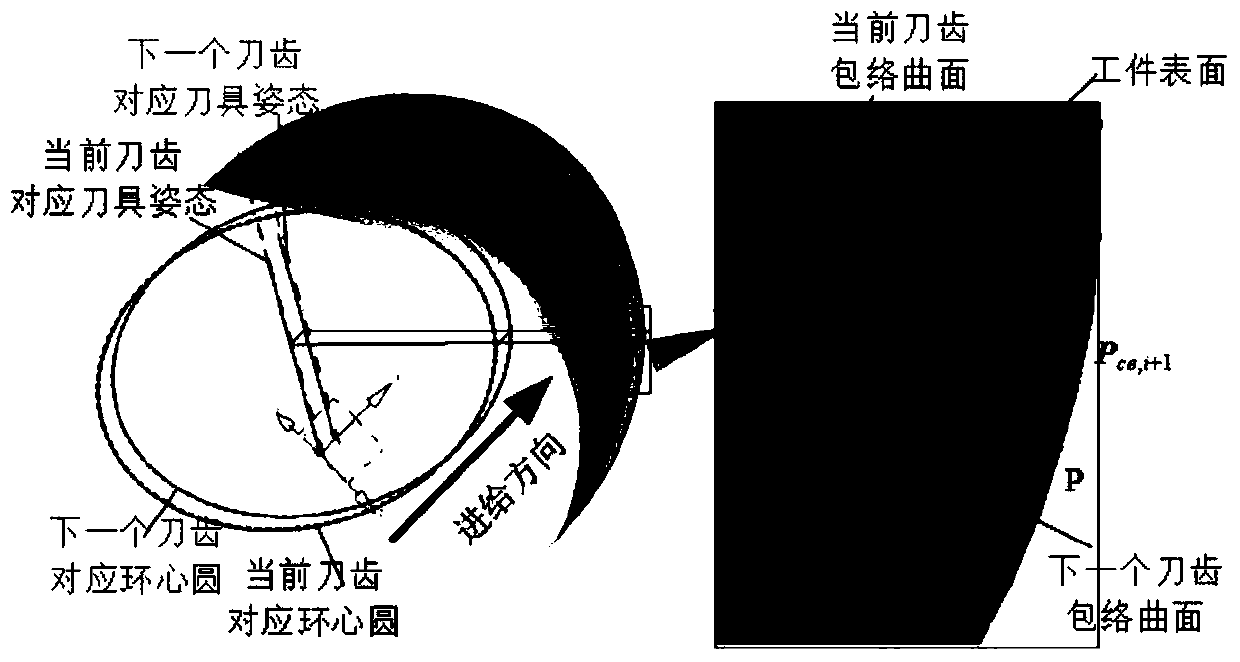

[0085] The tool deviation modeling method of the multi-axis machining system provided by the present invention includes five coordinate systems: tool coordinate system (t), machine tool coordinate system (m), tool contact local coordinate system (p), ellipsoid Coordinate system (e), workpiece coordinate system (w), different algebraic quantities or physical quantities are respectively established in their relevant coordinate systems, but in further derivation to be expressed in other coordinate systems, it needs to be transformed to In other coordinate systems, therefore, the modeling method of the present invention includes multiple coordinate transformations.

[0086] The method for modeling the tool deviation of the multi-axis machining system provided by the present invention includes the following steps S1-S10:

[0087] S1: Establish the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com