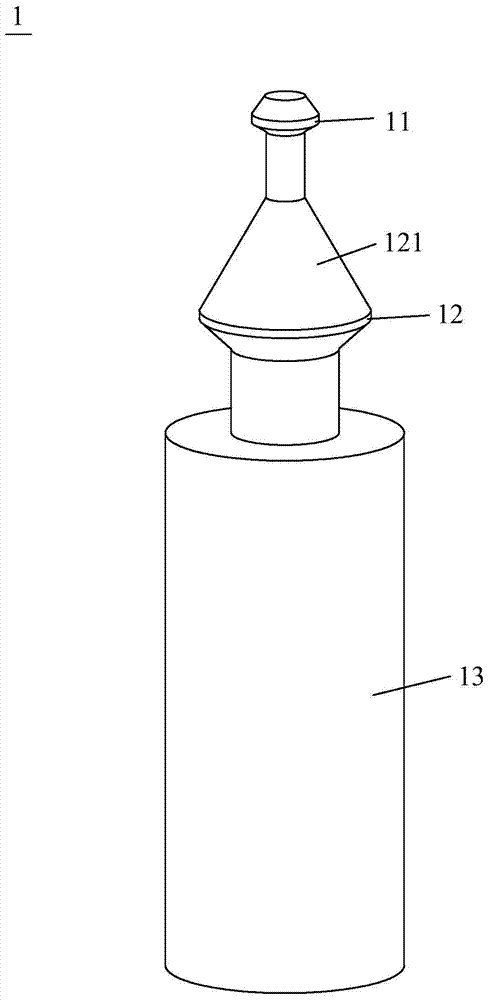

Control rod drive mechanism and its connection with control rods

A driving mechanism and control rod technology, which is used in the control of nuclear reactions, reactors, and greenhouse gas reduction, etc., can solve the problems of tripping, the disconnection of the control rod and the end of the detachable joint, etc., to ensure stable clamping and reduce accidents. The effect of the risk of tripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

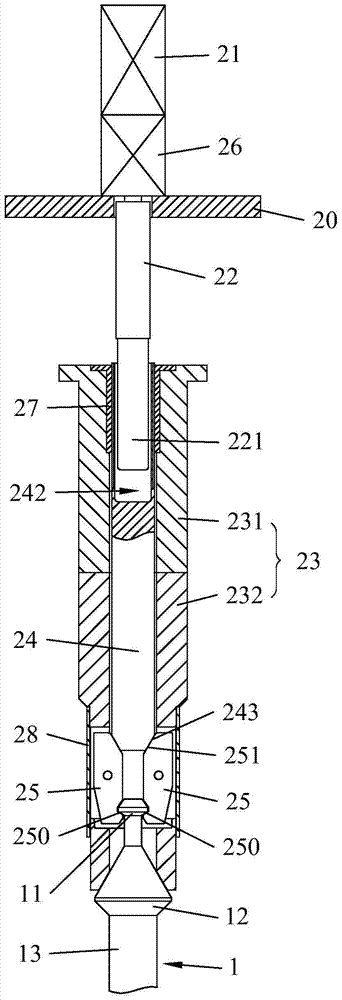

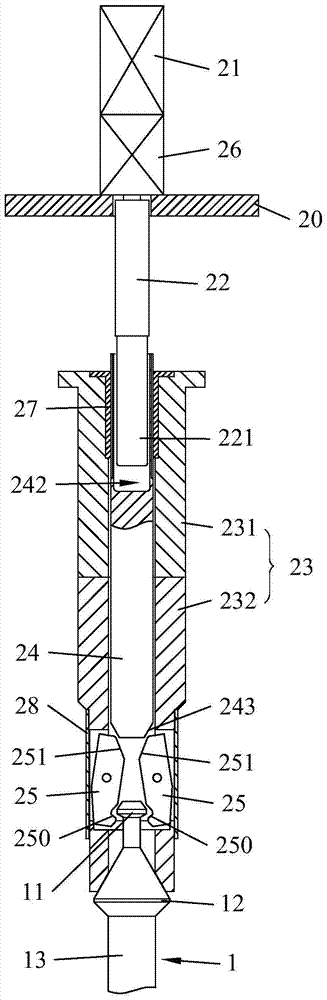

[0031] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0032] like figure 2As shown, the present invention provides a control rod drive mechanism, including a machine base 20, a motor 21, a transmission rod 22, a hollow shaft 23, a push rod 24 and at least three grippers 25; the hollow shaft 23 and the The base 20 is fixedly connected, the inner wall of the hollow shaft 23 is provided with a threaded area, the side wall of the push rod 24 is provided with external threads, and the push rod 24 is accommodated in the hollow shaft 23 and connected to the The threaded area is threaded, the motor 21 is fixed on the base 20 and drives the transmission rod 22 to rotate, the lower end of the transmission rod 22 extends into the hollow shaft 23 and is in contact with the push rod 24 The handle 25 is pivotally connected to the side wall of the hollow shaft 23, and the lower end of the handle 25 forms a hook su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com