Passenger car frame clamp

A frame and fixture technology, which is applied to vehicle parts, manufacturing tools, auxiliary devices, etc., can solve the problems that affect the welding efficiency, the fixture cannot be adjusted in real time, and cannot meet the requirements, so as to achieve the effect of ensuring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

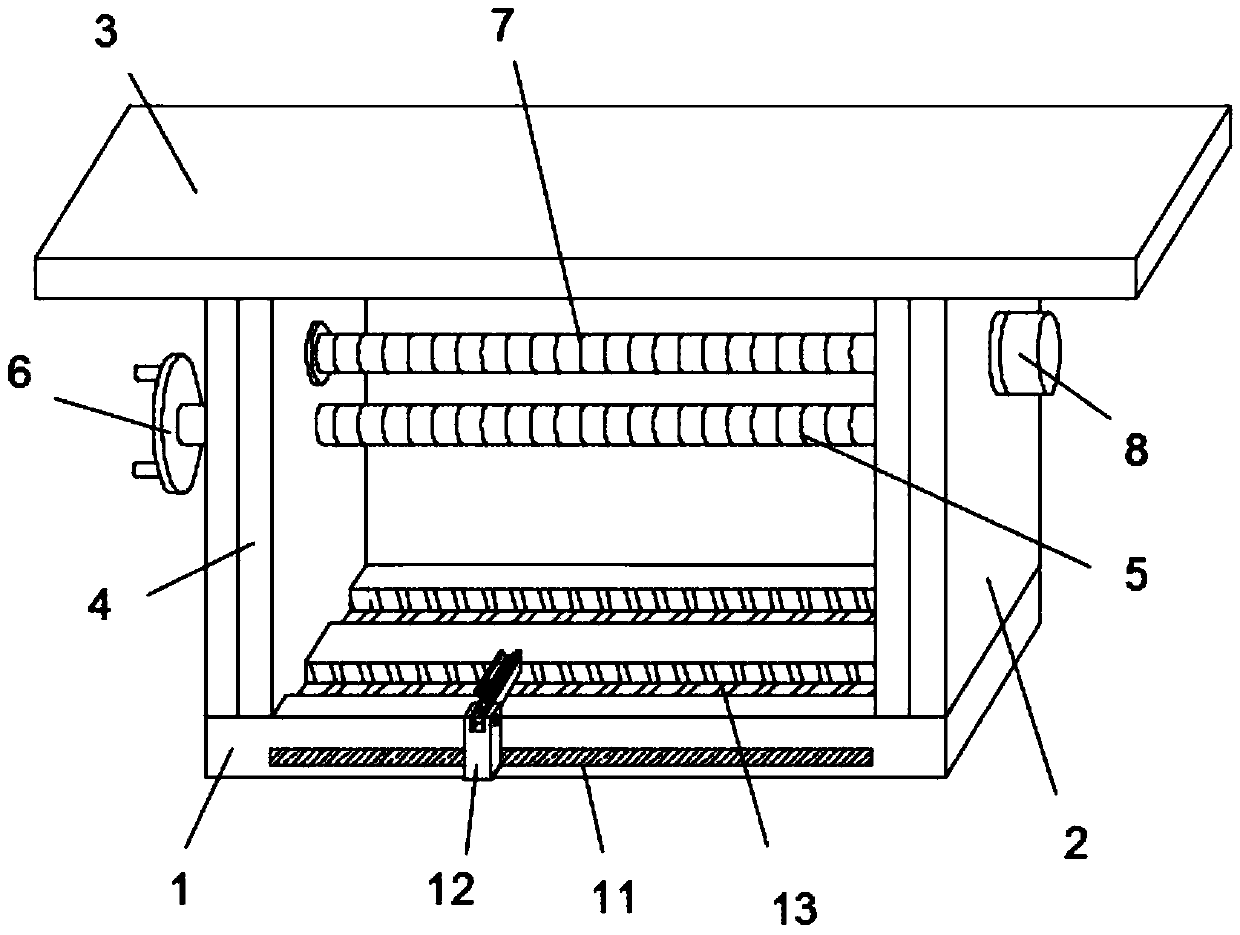

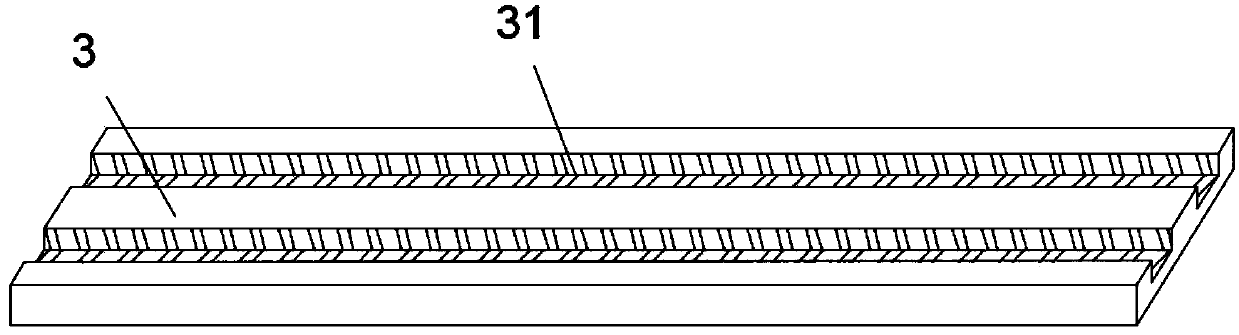

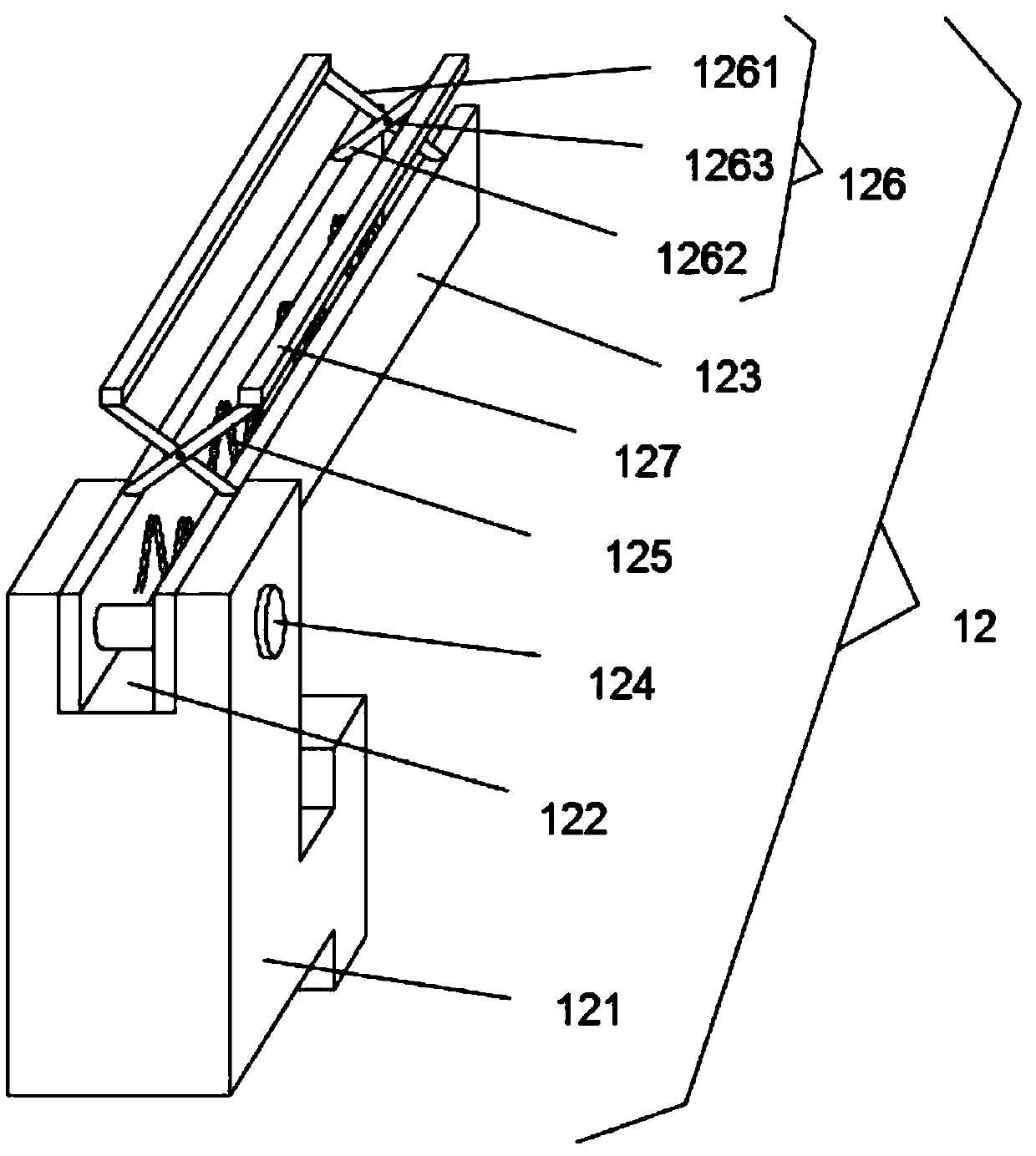

[0023] A passenger car frame clamp, comprising a base 1, a bar-shaped chute 11 is opened on the lower side of the front surface of the pedestal 1, and a positioning device 12 is slidably installed inside the bar-shaped chute 11, the base The upper surface of the base 1 is uniformly and horizontally provided with two first slide grooves 13, and the left and right sides of the upper surface of the base 1 are fixedly equipped with support plates 2, and the upper surface of the support plate 2 is fixedly equipped with a top plate 3, so The lower surface of the top plate 3 is provided with two second chute 31, and the two second chute 31 corresponds to the position of the two first chute 13 up and down, the first chute 13 and the second chute 31 There are two clamping plates 4 slidingly installed between them, and the outer surfaces of the two clamping plates 4 are closely attached to the support plate 2 on the same side, and the clamping plates 4 on both sides are used to clamp the...

Embodiment 2

[0029]A passenger car frame clamp, comprising a base 1, a bar-shaped chute 11 is opened on the lower side of the front surface of the pedestal 1, and a positioning device 12 is slidably installed inside the bar-shaped chute 11, the base The upper surface of the base 1 is uniformly and horizontally provided with two first slide grooves 13, and the left and right sides of the upper surface of the base 1 are fixedly equipped with support plates 2, and the upper surface of the support plate 2 is fixedly equipped with a top plate 3, so The lower surface of the top plate 3 is provided with two second chute 31, and the two second chute 31 corresponds to the position of the two first chute 13 up and down, the first chute 13 and the second chute 31 There are two clamping plates 4 slidingly installed between them, and the outer surfaces of the two clamping plates 4 are closely attached to the support plate 2 on the same side, and the clamping plates 4 on both sides are used to clamp the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com