Electric-leakage circuit breaker with reverse-wiring structure

A leakage circuit breaker and reverse wiring technology, applied in the direction of circuits, electric switches, electrical components, etc., can solve the problems of reduced service life, damage to leakage release coils, etc., and achieve the effect of ensuring normal use and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

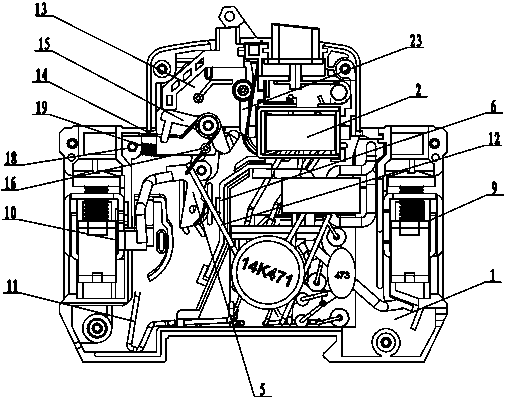

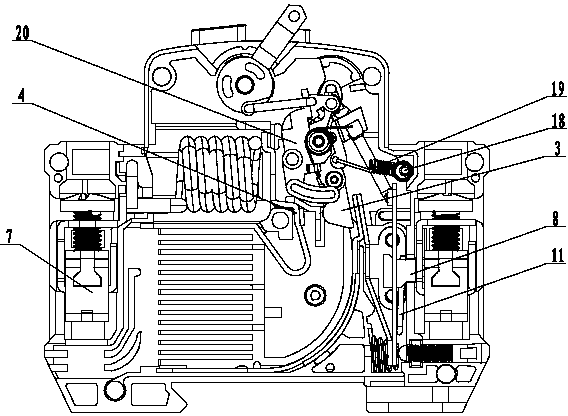

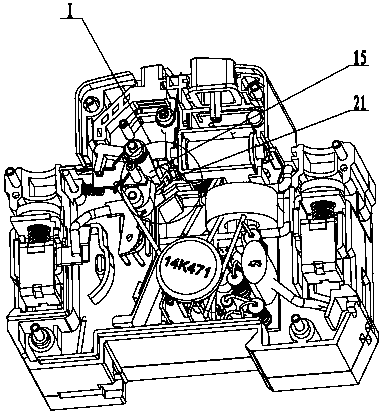

[0018] Embodiments of the present invention will be further described below with reference to the accompanying drawings:

[0019] As shown in the figure, a leakage circuit breaker with a reverse wiring structure includes a housing 1, an operating mechanism, a contact mechanism, a leakage release 2, and terminals. The contact mechanism includes L-pole movable contacts 3, L The pole static contact 4, the N pole moving contact 5 and the N pole static contact 6, the L pole moving contact 3 and the N pole moving contact 5 are connected in linkage, and the connecting terminals include the L pole incoming terminal 7, The L pole outgoing line terminal 8, the N pole incoming line terminal 9 and the N pole outgoing line terminal 10 also include a live wire 11 and a neutral wire 12, and one end of the live wire 11 and the neutral wire 12 is connected to the leakage release 2 respectively, and the The other end of the live wire 11 is electrically connected to the L-pole outlet terminal 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com