Corrugated case print fluting machine with adjustable tool distance

A corrugated box and slotting machine technology, applied in papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve the problems of no waste discharge device, large labor force, affecting production efficiency, etc., to achieve labor saving, convenient operation, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

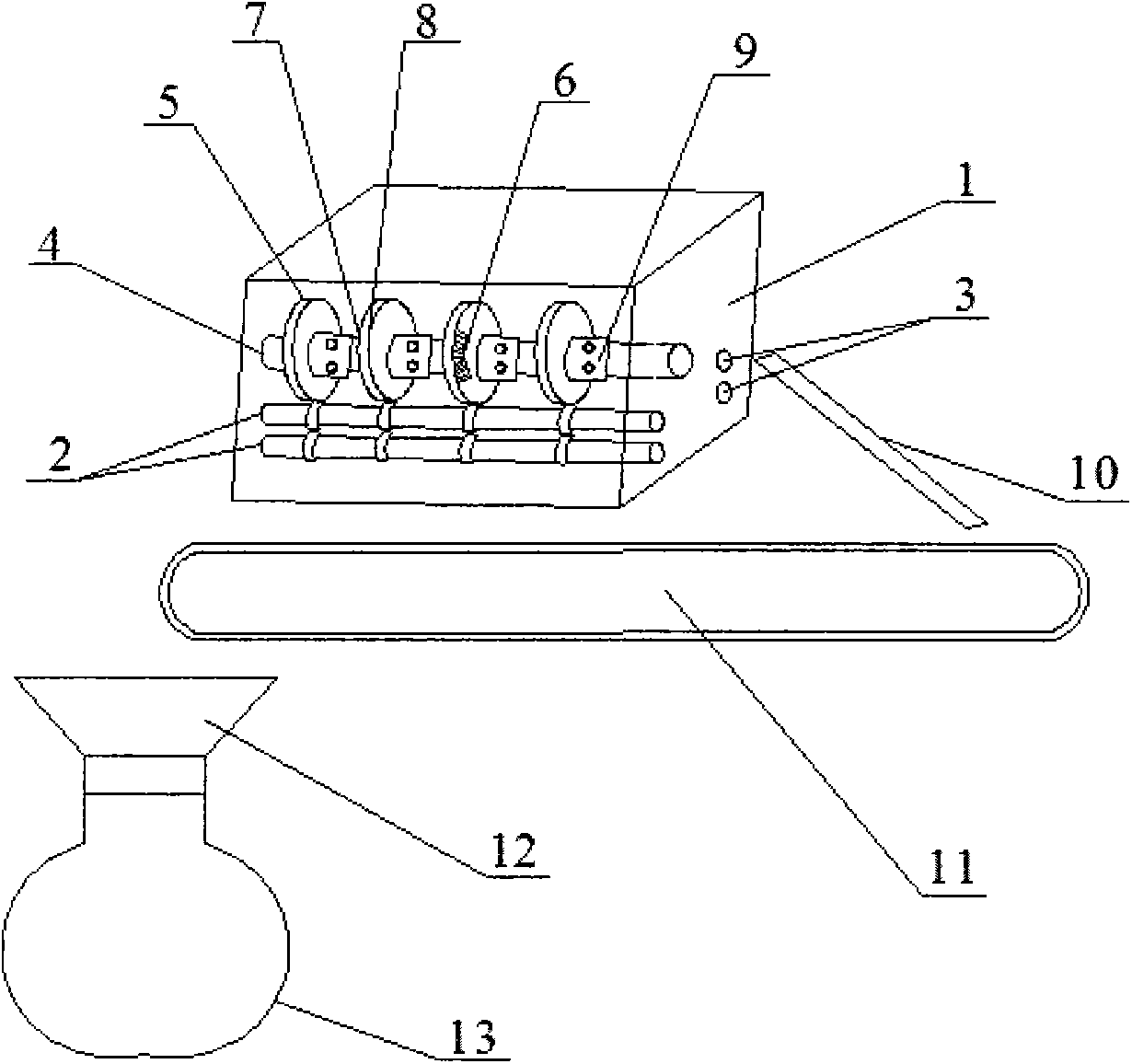

[0015] Such as figure 1 As shown, a corrugated box printing and slotting machine with adjustable knife distance of the present invention comprises a frame 1 on which a first transmission wheel 2 and a second transmission wheel 3 are arranged, and the first transmission wheel 2 and the second transmission wheel 3 Pressing roller 4 is arranged between the second driving wheel 3, and knife rest 5 is arranged on pressing roller 4, and dial 6 is provided on knife rest 5, and it can be seen that first blade 7 and second blade are arranged on knife rest 5 8. The distance between the first blade 7 and the second blade 8 can be measured through the dial 6. The blades of the first blade 7 and the second blade 8 are provided with serrations, so that the slotting operation of the carton can be performed more qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com