Motorcycle tail lamp assembly and motorcycle with same

A technology for motorcycles and taillights, which is applied to bicycle accessories, transportation and packaging, and optical signals. It can solve the problems of increasing the number of taillight parts, difficulty in ensuring relative position accuracy, and uneven gaps, so as to improve relative position accuracy and improve The effect of commercial appearance and uniform connection gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

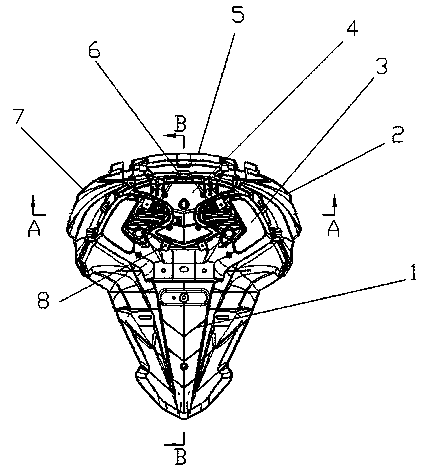

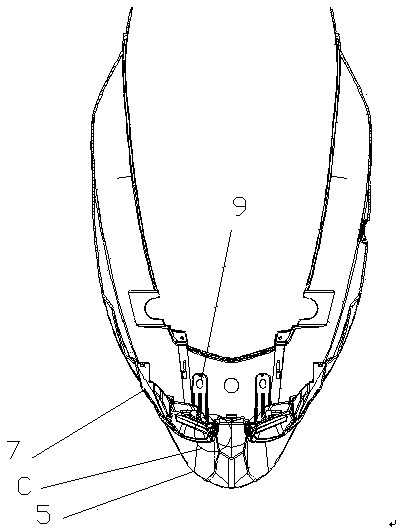

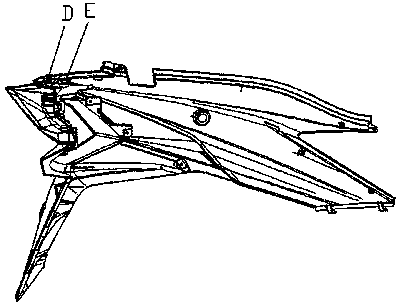

[0021] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 The cross-sectional view at A; image 3 for figure 1 Sectional view at B. As shown in the figure, the motorcycle tail light assembly in this embodiment includes a tail light assembly and a tail assembly that is arranged around the tail light assembly and is detachably fixedly connected to the tail light assembly. The tail assembly is a related component around the tail light assembly, such as : tail cover 5, left tail cover 2, right tail cover 7, fender 1, etc., the edge of the tail light assembly is detachably fixedly connected with the tail assembly to form a tail light assembly, and then fixedly connected with the rear of the car body. In terms of motorcycle taillights and their related components being fixedly connected to the vehicle frame through brackets, the present invention first fixes the taillight assembly and the peripheral tail assembly to form a tailligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com